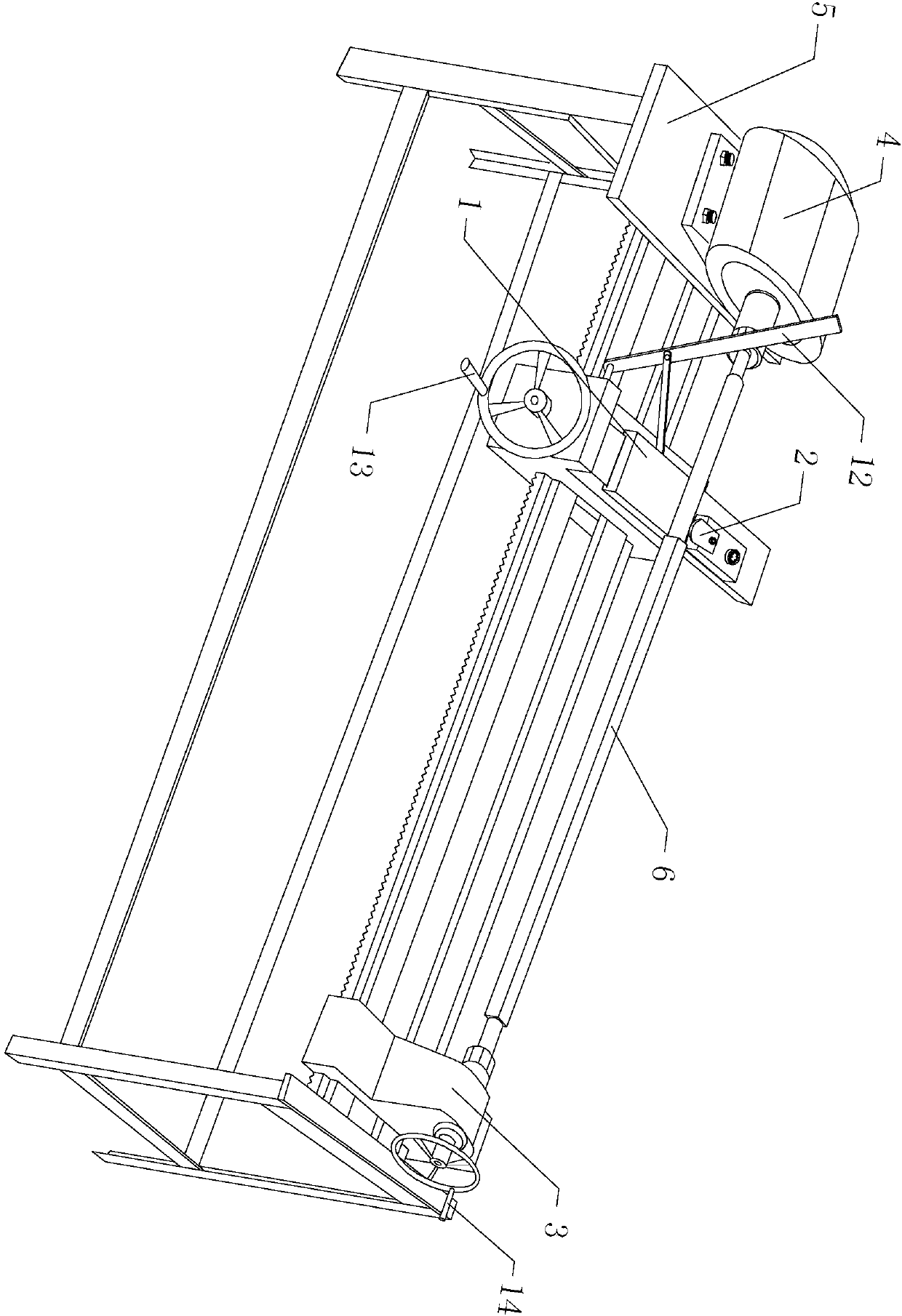

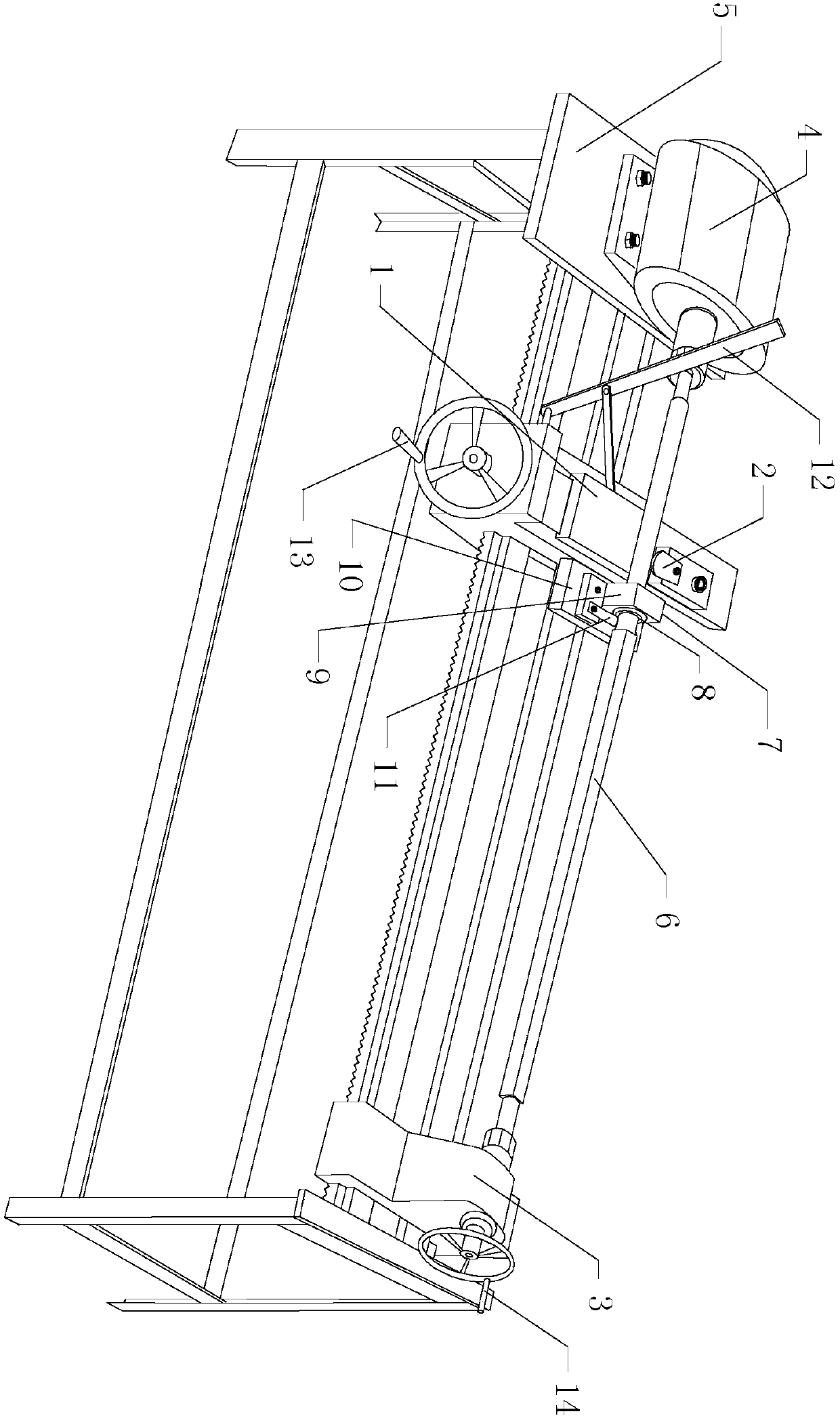

Long wood handle turning and fixing device

A technology of fixing device and wooden handle, used in woodworking lathes, wood processing appliances, manufacturing tools, etc., can solve the problems of increased impact strength of turning tool bits, increased turning depth of turning tool bits, large surface differences, etc. Product qualification rate, avoid strong impact, prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention. Apparently, the described embodiments are only some of the embodiments of the present invention, but not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention.

[0019] In order to understand the content of the present invention more easily, the following definitions are made: taking the observer as a reference, the observer faces the drawing, the front in the content is the part far away from the observer in the figure, and the back in the content is the part close to the observer in the figure The left part of the content is the left part of the observer in the figure, and the right part of the content is the right ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap