Straw storing structure based on straw extracted dietary fibers

A dietary fiber and straw technology, applied in the field of straw, can solve the problems of inconvenient operation, low efficiency, stacking of straw, etc., and achieve the effect of convenient use, easy operation and use, and convenient placement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

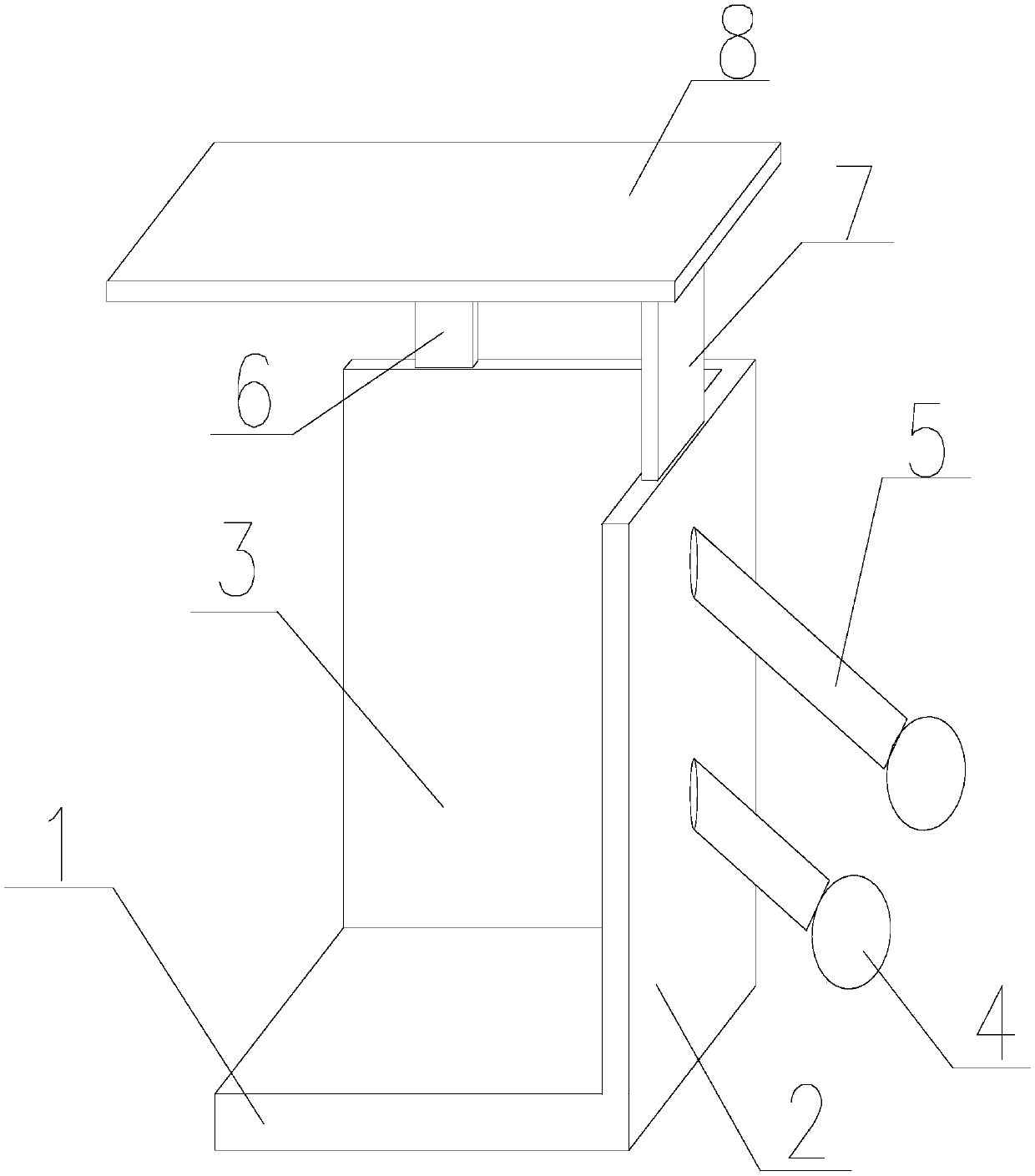

[0023] Such as figure 1 As shown, the present invention is based on the straw storage structure for extracting dietary fiber from straws, including a placement plate 1, and two adjacent side surfaces of the placement plate 1 are connected with vertical baffles A2 and B3, and the baffles A2 is provided with two mutually parallel inclined placing rods 5 on the vertical side away from the placing plate 1, and the placing rods 5 are obliquely downwardly inclined, and the included angle between the placing rods 5 and the horizontal line is 30 degrees, so The bottom of the placement rod 5 is connected with a pulley 4, the pulley 4 is located on the same straight line, and the angle between the straight line at the bottom of the two pulleys 4 and the straight line where the placement plate 1 is located is 30 degrees; between the two placement rods 5 The distance is half of the length of the baffle A2, and the upper ends of the baffle A2 and the baffle B3 are respectively connected wi...

Embodiment 2

[0025] The straw storage structure based on extracting dietary fiber from straws includes a placement board 1, and two adjacent sides of the placement board 1 are connected with vertical baffles A2 and B3, and the baffles A2 are away from The vertical side of placing plate 1 is provided with two mutually parallel inclined placing rods 5, and described placing rods 5 are obliquely downwardly inclined, and the included angle between placing rods 5 and the horizontal straight line is 30 degrees, and described placing The bottom of bar 5 is connected with pulley 4, and described pulley 4 is located on the same straight line, and the angle between the straight line at the bottom of two pulleys 4 and the straight line where plate 1 is placed is 30 degrees; the distance between the two placed bars 5 It is 1 / 2 of the length of the baffle plate A2, the upper ends of the baffle plate A2 and the baffle plate B3 are respectively connected with a telescopic telescopic rod A7 and a telescopi...

Embodiment 3

[0027] The straw storage structure based on extracting dietary fiber from straws includes a placement board 1, and two adjacent sides of the placement board 1 are connected with vertical baffles A2 and B3, and the baffles A2 are away from The vertical side of placing plate 1 is provided with two mutually parallel inclined placing rods 5, and described placing rods 5 are obliquely downwardly inclined, and the included angle between placing rods 5 and the horizontal straight line is 30 degrees, and described placing The bottom of bar 5 is connected with pulley 4, and described pulley 4 is located on the same straight line, and the angle between the straight line at the bottom of two pulleys 4 and the straight line where plate 1 is placed is 30 degrees; the distance between the two placed bars 5 It is 1 / 2 of the length of the baffle plate A2, the upper ends of the baffle plate A2 and the baffle plate B3 are respectively connected with a telescopic telescopic rod A7 and a telescopi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com