Glass sheet stacking rack

A technology for stacking racks and glass sheets, which is applied to conveyor objects, furnaces, lighting and heating equipment, etc., to achieve stable transmission, prevent unreliable coordination, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

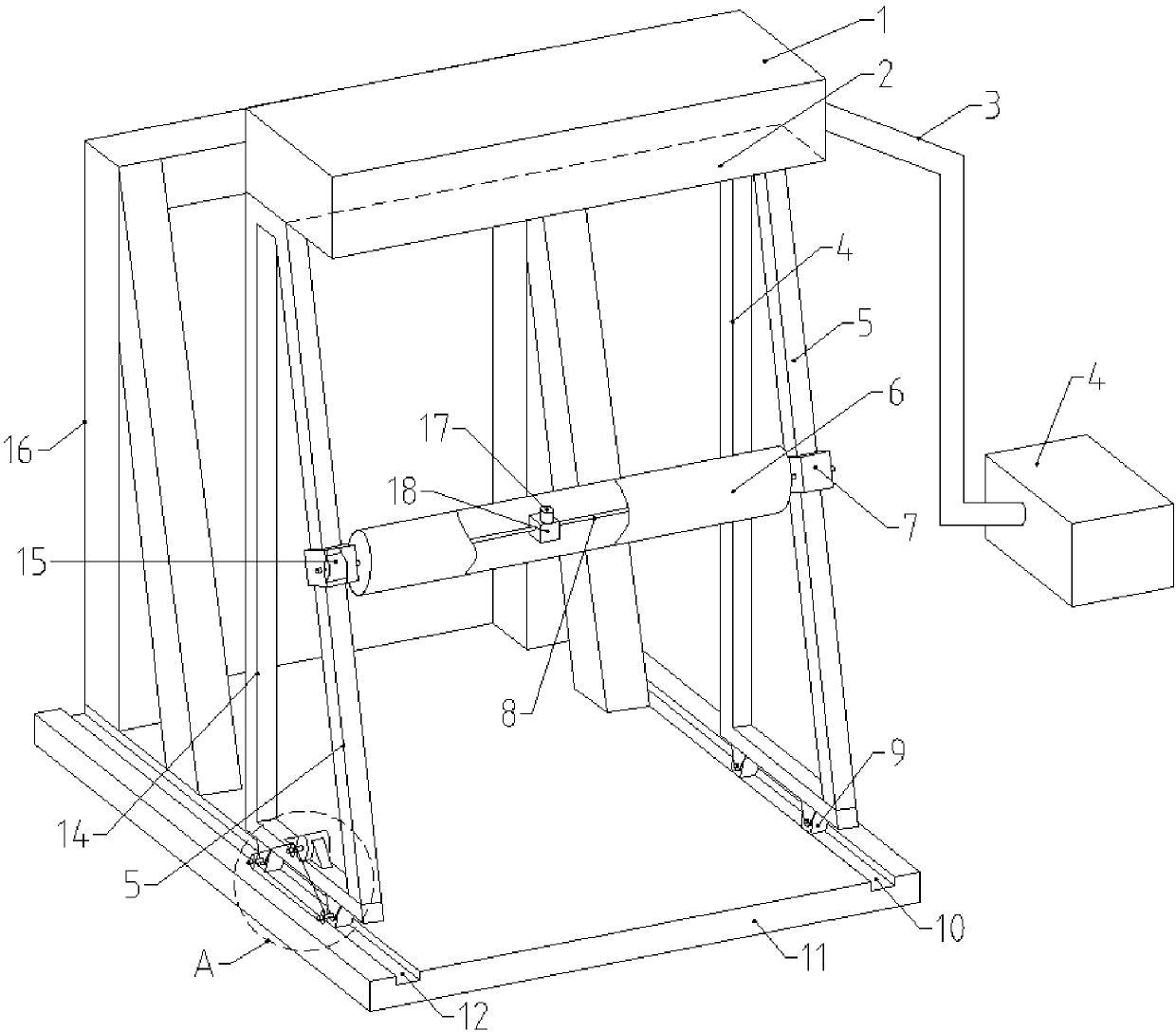

[0020] A glass sheet stacking rack, comprising a bottom plate 11 provided with a support frame 16, characterized in that: the upper surface of the bottom plate 11 is respectively provided with a guide groove a12 and a guide groove b10 on the left and right sides of the support frame 16, and the guide groove a12 and the guide groove b10 There are L-shaped sliding bracket a14 and sliding bracket b4 respectively, the sliding bracket a14 is provided with a power device 13, the height of sliding bracket a14 and sliding bracket b4 is higher than that of the supporting frame 16, the top of sliding bracket a14, sliding bracket b14 and The racks 5 are connected to the bottom ends obliquely, and the rotating shaft 8 sleeved with the cleaning roller 6 is arranged horizontally between the sliding bracket a14 and the sliding bracket b4. Both ends of the rotating shaft 8 cooperate with the rack 5 through the gear 15, and the rotating shaft 8 passes through The transmission mechanism 18 is co...

Embodiment 2

[0024] This embodiment improves on the basis of Embodiment 1:

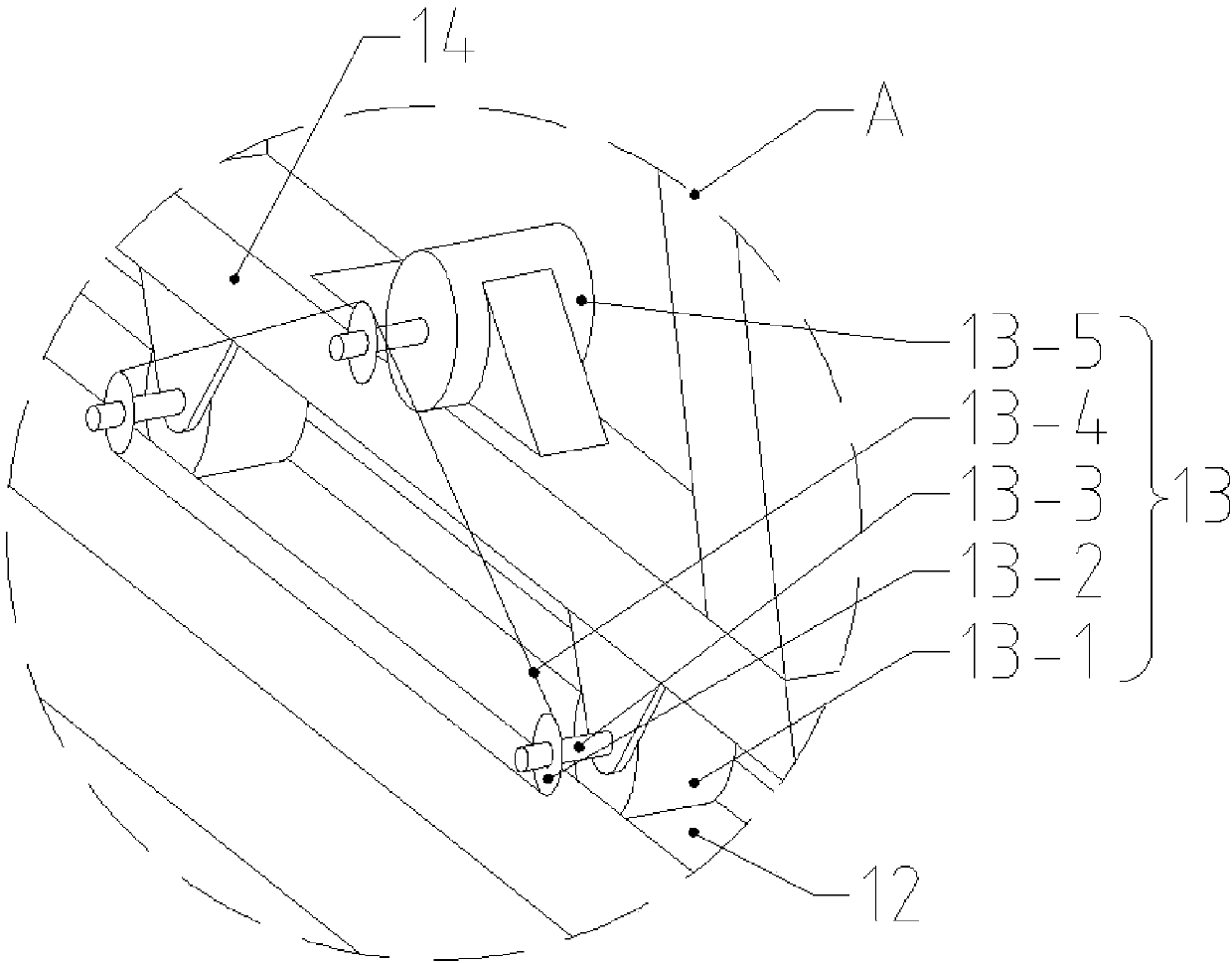

[0025] The power unit 13 includes a plurality of driving shafts 13-3 that are provided with driving rollers 13-1, the driving shafts 13-3 are arranged at the bottom of the sliding bracket a14, the driving rollers 13-1 are in contact with the guide groove a12, and the driving shafts 13-1 3 ends are provided with several identical sprocket wheels 13-2, and the sprocket wheels 13-2 are connected with the active motor 13-5 arranged on the sliding bracket a14 through the chain 13-4, and the bottom end of the sliding bracket b4 is provided with a number of guide motors. The groove b10 contacts the mating driven roller 9 .

[0026] The advantages of the above improvements are that the driving motor drives the driving roller by utilizing the cooperation of the sprocket and the chain, the transmission of the sprocket and the chain is stable, and the structure is simple.

Embodiment 3

[0028] This embodiment is improved on the basis of the above embodiments:

[0029] The transmission mechanism 18 is a worm gear mechanism, the gear 15 is arranged in the sliding box 7 , and the sliding box 7 is movably sleeved on the rack 5 .

[0030] The advantages of the above improvements are: the worm and worm mechanism is self-locking, preventing the cleaning roller from being damaged by falling along the rack under the action of gravity. At the same time, a sliding box is set on the rack, and the sliding box and the rack are clamped and pressed together. Gears prevent the gears from being loosely matched with the rack.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com