Apparatus and method for combined testing of gas content andC1-C15 light hydrocarbon components of rock.

A C1-C15, combined testing technology, applied in the field of oil and gas exploration and development, can solve the problems of low work efficiency, desorption and loss of gas substances, harsh environment and experimental technology requirements, etc., to improve work efficiency, easy operation, overcome non- Effect of Homogeneity and Ambient Temperature Influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with accompanying drawing.

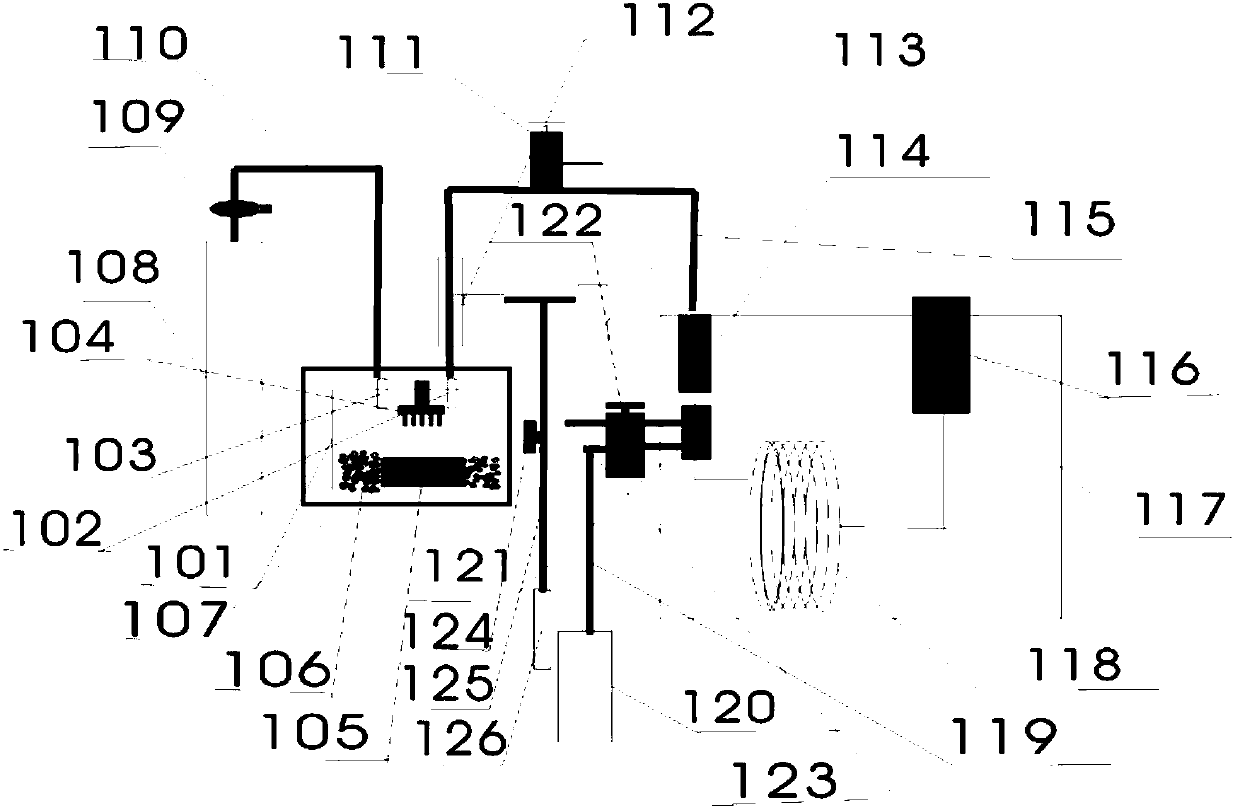

[0037] figure 1 It is a schematic diagram of the device for joint testing of rock gas content and C1-C15 light hydrocarbon components. Including sealed sample broken sample degassing system and online light hydrocarbon analysis system (not indicated in the figure).

[0038] The sealed broken sample degassing system includes a sealed broken sample tank 101 and a heating box 107 set on the sealed broken sample tank 101; the online light hydrocarbon analysis system includes a chromatographic box 117, which is arranged on the top side of the chromatographic box 117 vaporization chamber 114, the detector 116 arranged on the other side of the chromatographic case 117 top, the smart cold trap 121 arranged inside the chromatographic case, the front end of the chromatographic column 118 passes through the smart cold trap 121 and is connected with the vaporization chamber 114, so T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com