Oxygen reduction plant and method for configuring an oxygen reduction plant

A technology of oxygen and oxygen concentration, used in fire rescue and other directions, can solve the problem of air tightness, and achieve the effect of reducing installation cost, minimizing wear, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

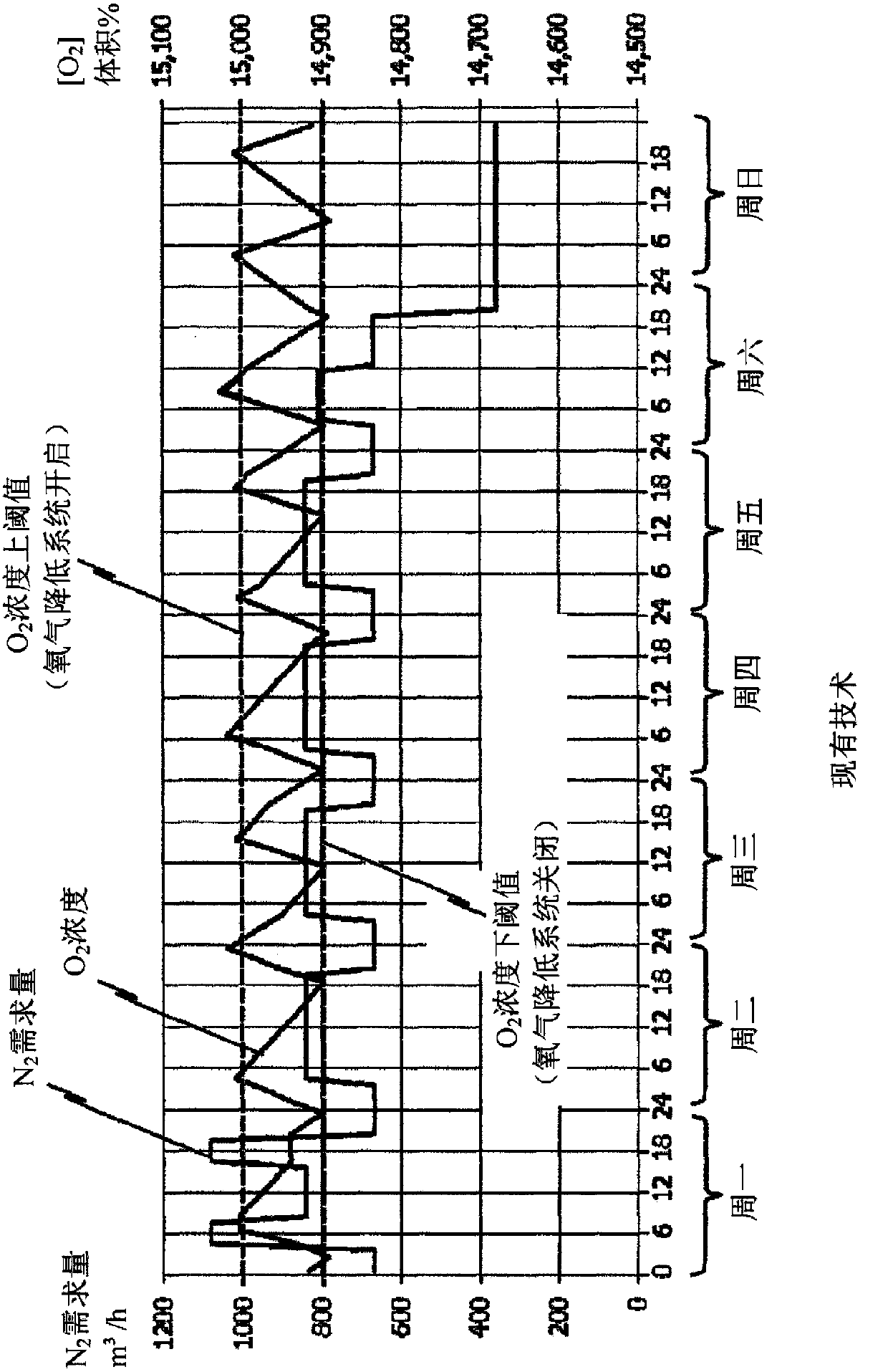

[0040] figure 1 A basic timing diagram representing the mode of operation of a conventional oxygen reduction system known in the art is shown. This is an oxygen reduction system for reducing the oxygen concentration in the space atmosphere of an enclosed area below a predetermined and reduced concentration (=working concentration) compared to the oxygen concentration of normal ambient air. figure 1 The relevant time periods of the time graph total one week (7 days).

[0041] figure 1 In particular, the chronological development of the oxygen concentration in the space atmosphere of an enclosed area is depicted. It can be seen that the oxygen concentration is always in the range between about 15.0% by volume and 14.9% by volume. This is a typical control range defined by the upper and lower thresholds of the oxygen concentration in the atmosphere of the enclosed area space.

[0042] The upper threshold of the concentration of oxygen in the atmosphere of the enclosed area re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com