Process for producing modified olefin polymer in an extruder

A technology for olefin polymers and extruders, applied in the field of modified olefin polymers, can solve problems such as complex equipment, increased input costs, loss of functional unsaturated compounds, etc., and achieve low input and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

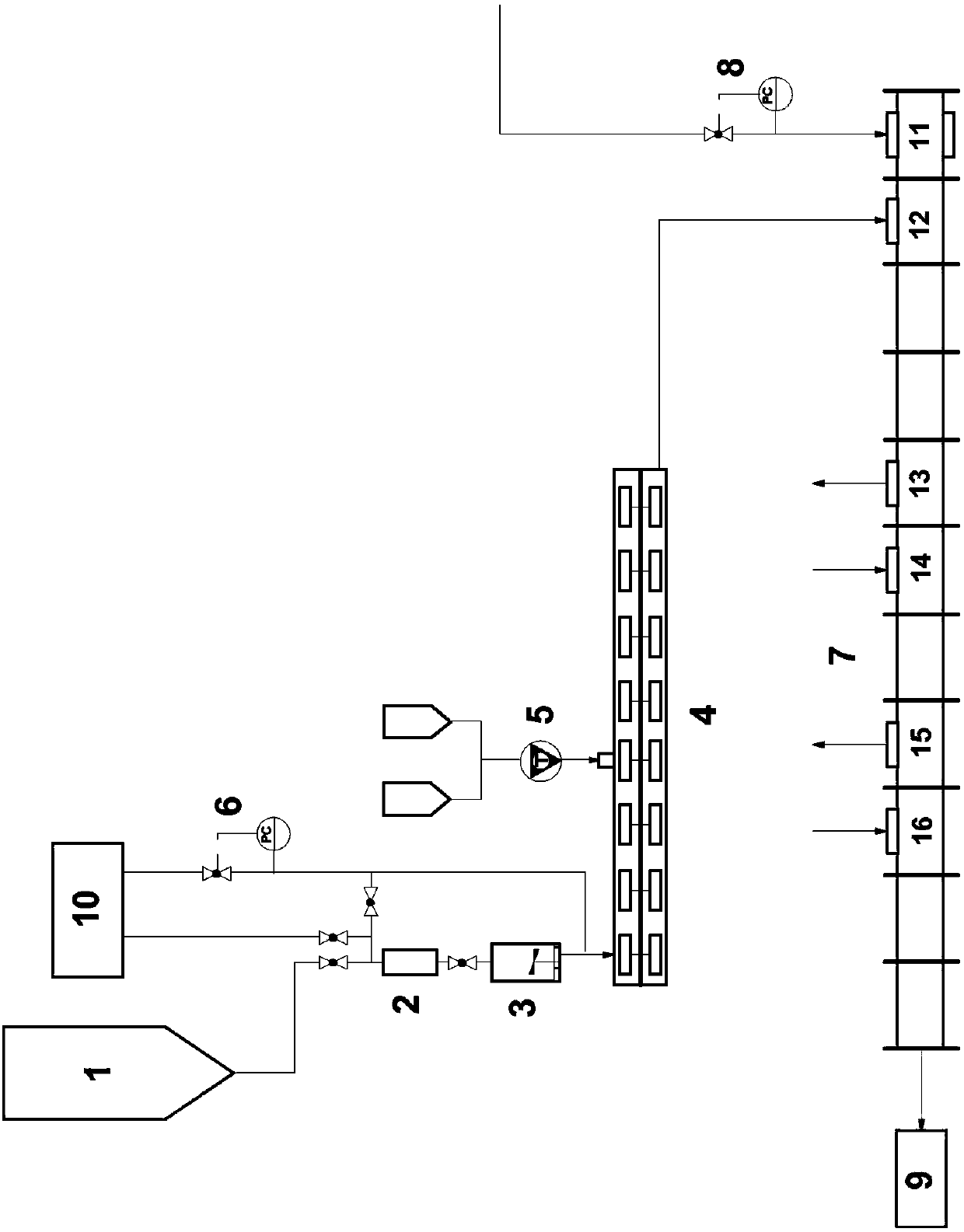

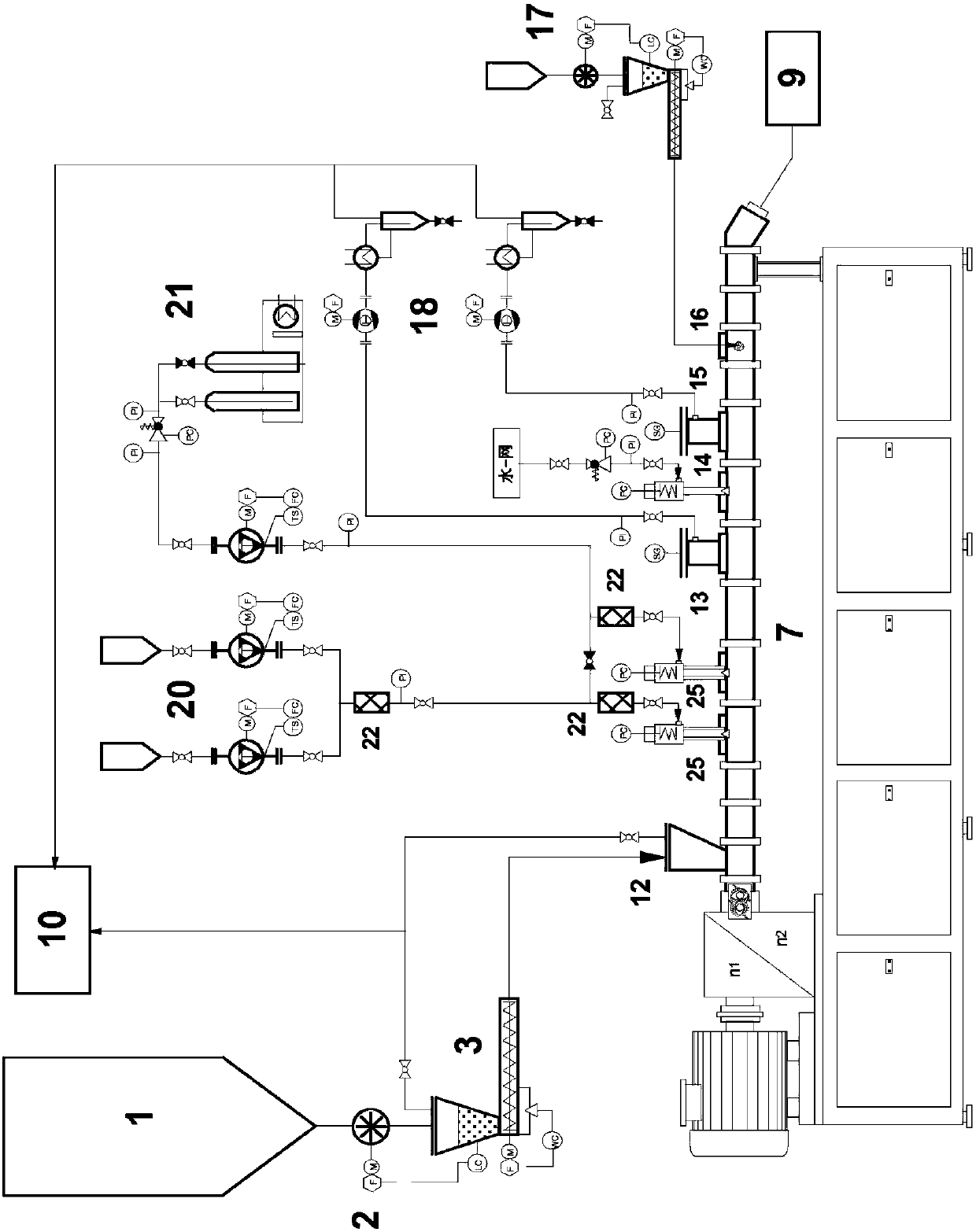

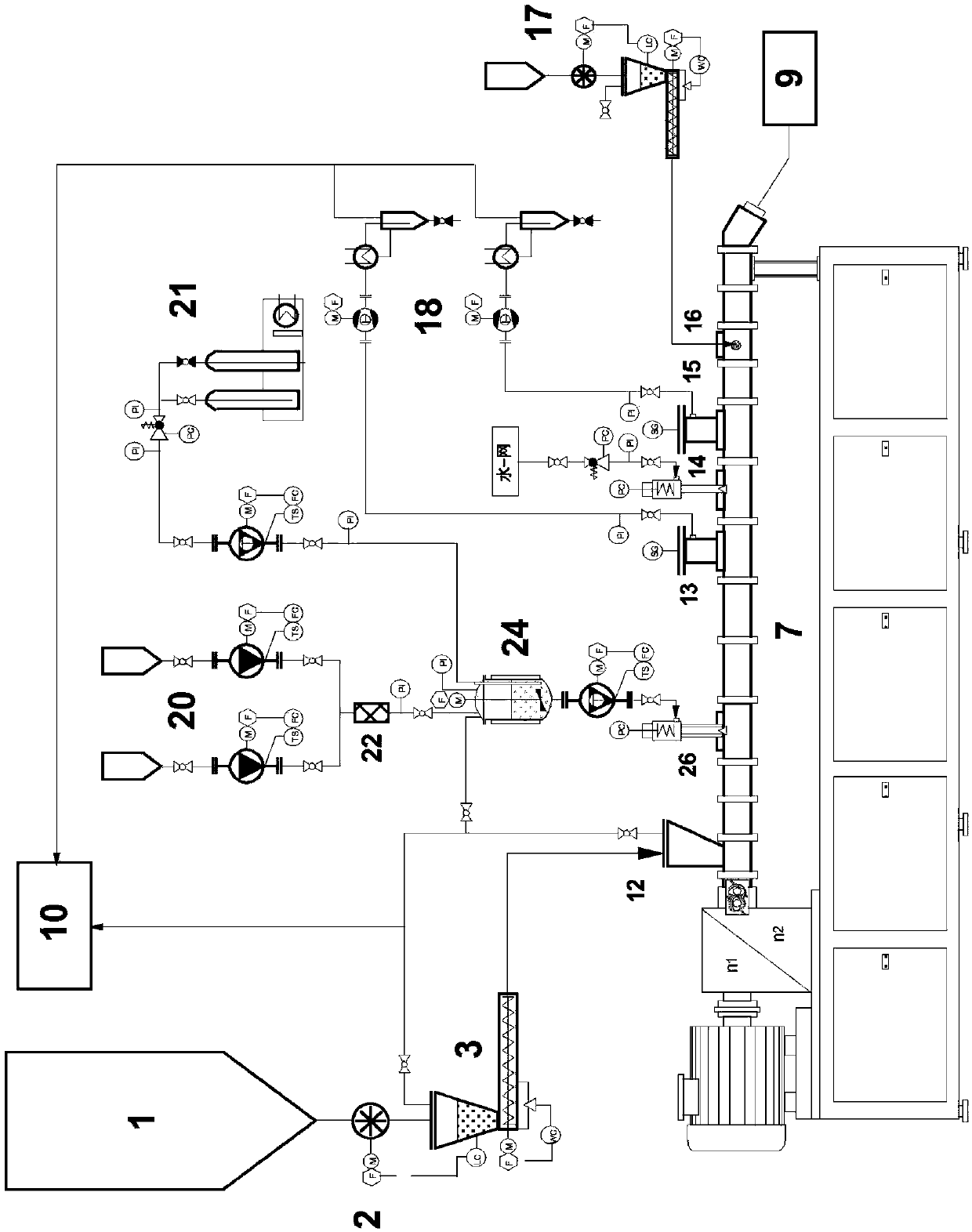

[0281] A ZSK 30 co-rotating twin-screw extruder with an L / D of 38 was used for reactive extrusion below. The powder was fed at a distance of 1.5 L / D from the upstream end of the screw. The peroxide and / or butadiene feed points were at 8 and 12 L / D from the upstream end of the screw. The additive feed is at 24 L / D and the vacuum port is at 33 L / D. In the L / D range of 9 to 24 the screw contains mixing elements, whereas in the L / D range of 1 to 9 and 24 to 38 the screw contains conveying elements. Barrel temperatures were about 110°C at the upstream end of the melting zone, 180 to 200°C in the mixing zone, and about 220°C in the die zone. The vacuum was set at -0.25 barg.

[0282] Polymer 1 was introduced into the feed throat of the extruder. 1,3-butadiene and the above-mentioned peroxide solution 1 were introduced into the liquid feed port where the L / D was 8, so that the feed rates of the peroxide solution and butadiene were propylene average 0.72% and 0.23% by weight of t...

Embodiment 2

[0285] The procedure of Example 1 was repeated except that Polymer 5 was used as the polymer starting material. The feed rates of peroxide solution 1 and 1,3-butadiene are shown in Table 1.

Embodiment 3

[0287] The procedure of Example 1 was repeated except that Polymer 2 was used as the polymer raw material and butadiene was introduced into the feed port at L / D 12. The feed rates of peroxide solution 1 and 1,3-butadiene are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| half-life | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com