Dehydrated potherb mustard and pickling method thereof

A technology of kohlrabi and water, which is applied in the preservation of fruits and vegetables, food preservation, preservation of food ingredients as anti-microbials, etc., can solve environmental pollution, can not maintain the crisp taste and fragrance of kohlrabi, and waste cooking soy sauce. resources and other issues, to achieve the effect of reducing production costs, maintaining flavor characteristics, and shortening the marinating cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

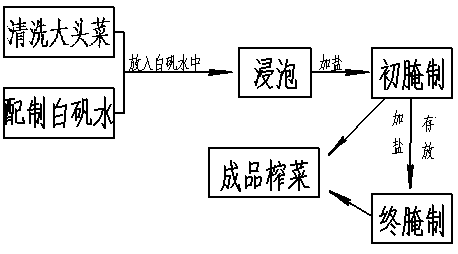

[0029] The water dehydration kohlrabi and the pickling method of the present invention mainly include the preparation of the dehydration solution, the soaking of the kohlrabi, and the pickling of the kohlrabi;

[0030] The first step, the production of dehydration solution: prepare alum and water in proportion and put it into water to make it melt. The obtained solution is the alum aqueous solution that can dehydrate kohlrabi. The ratio of the alum to water is 1:15 to 1:25, the higher the ratio, the shorter the soaking time of the kohlrabi in the alum aqueous solution, and the lower the ratio, the longer the soaking time of the kohlrabi in the alum aqueous solution. The described alum aqueous solution can be reused. When the concentration of the alum aqueous solution after soaking the kohlrabi is reduced, the alum is directly added and mixed into the aqueous solution, and the alum can also be converted into a high-concentration alum aqueous solution and then added to the alum a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com