Method for improving concrete floor building efficiency of construction workers

A technology for construction workers and concrete, applied in construction, road repair, roads, etc., can solve problems such as dent deformation, embossing mold sticking, etc., to achieve the effect of reducing time cost, increasing friction, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

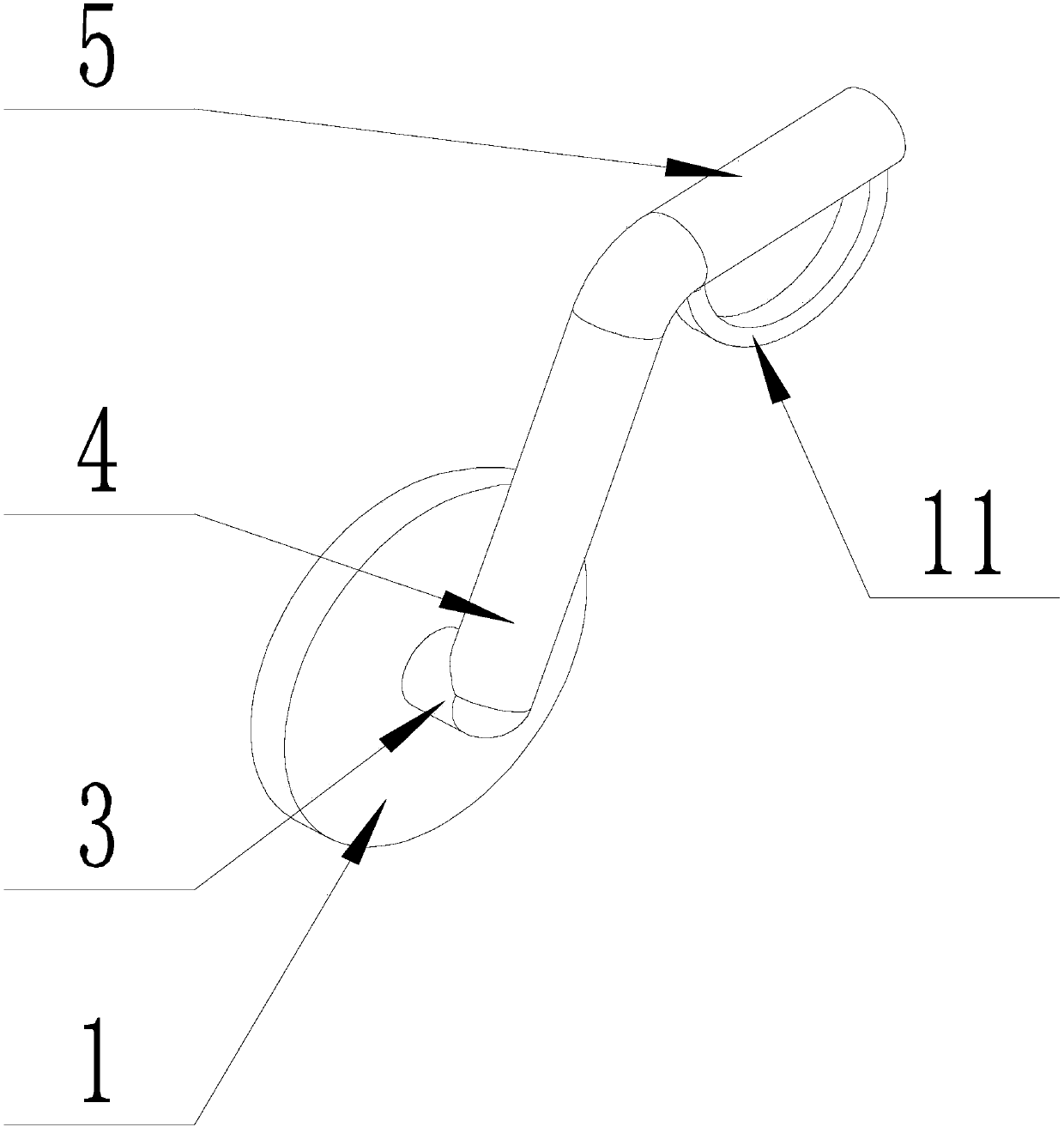

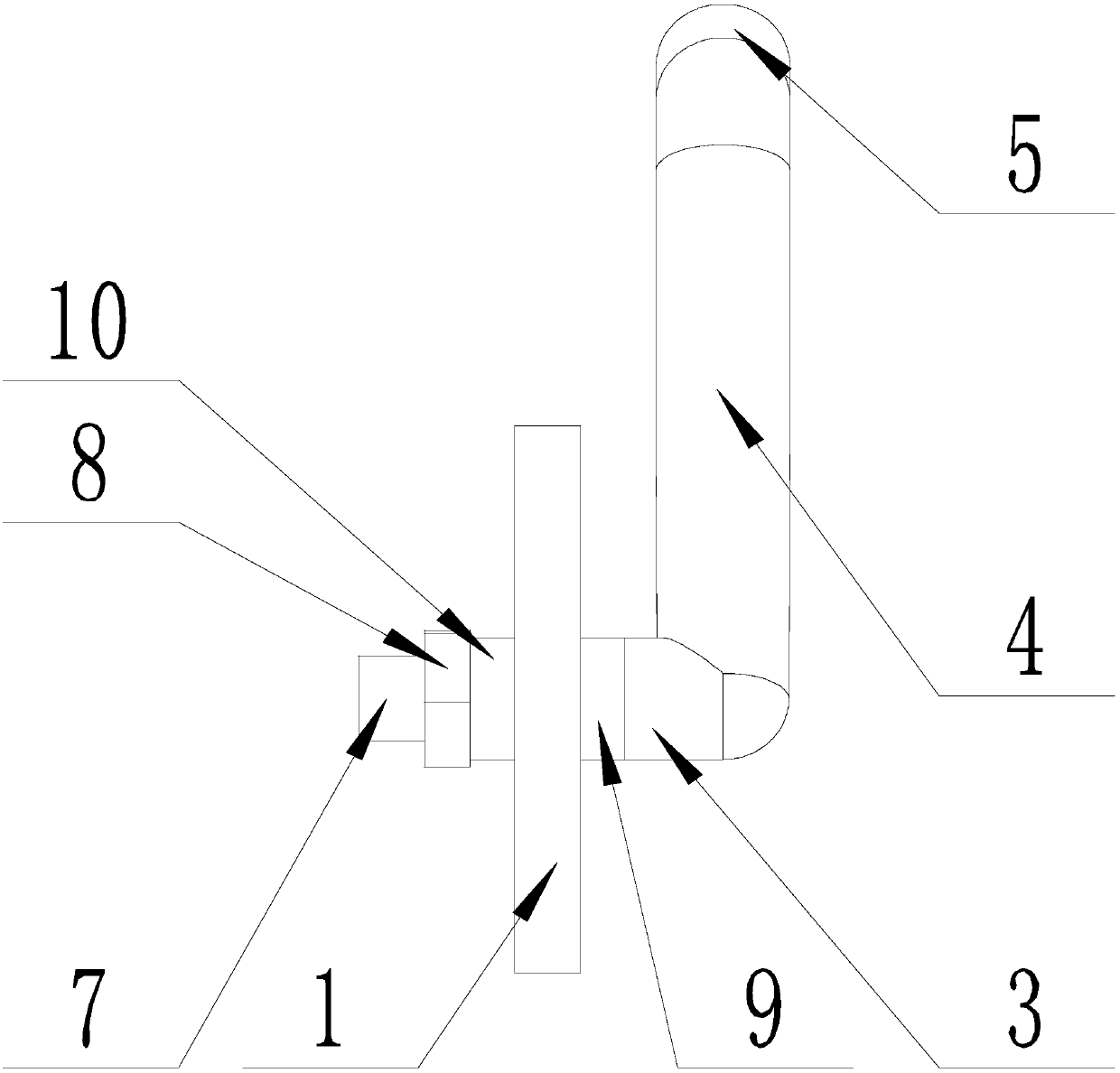

[0035] Such as Figure 1-Figure 4 Shown, the present invention improves the method that builder builds concrete floor efficiency, comprises the steps:

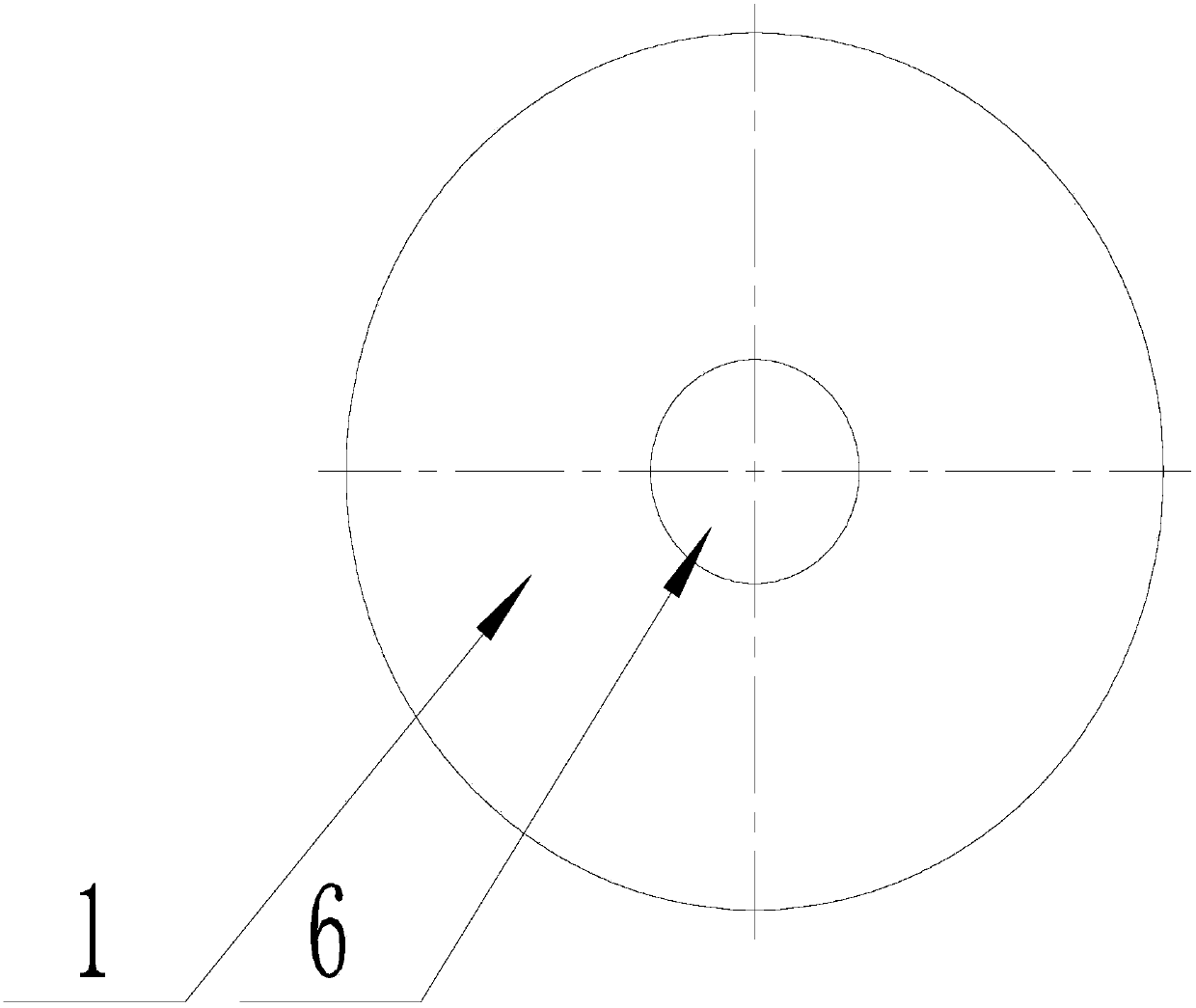

[0036] Step A: first set the rubber ring I9 on the installation shaft 2, and make contact with the end of the gear shaft 3 away from the connecting shaft 4, and then set the scraper plate 1 on the installation shaft 2 through the installation hole 6;

[0037] Step B: Set the nut 8 on the screw 7, and rotate the nut 8 until the rubber ring II10 and the rubber ring I9 are in contact with the scraper disc 1;

[0038] Step C: Hold the handle 5, and then move the scraping tray 1 to the dent formed by the embossing mold on the concrete floor, and move the scraping tray 1 back and forth along the groove wall of the dent to remove the dent. Scrape off the raised parts of the bottom of the tank and the wall of the tank.

[0039] During use, hold the handle 5, then move the scraper tray 1 into the indentation formed by the embossing m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com