Residue squeezing water tank

A technology for sinks and residues, which is applied in water supply devices, indoor sanitary plumbing devices, buildings, etc., can solve the problems of inconvenient use, unstable fixing of various parts, etc., and achieve strong applicability, wide applicability, and good separation effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

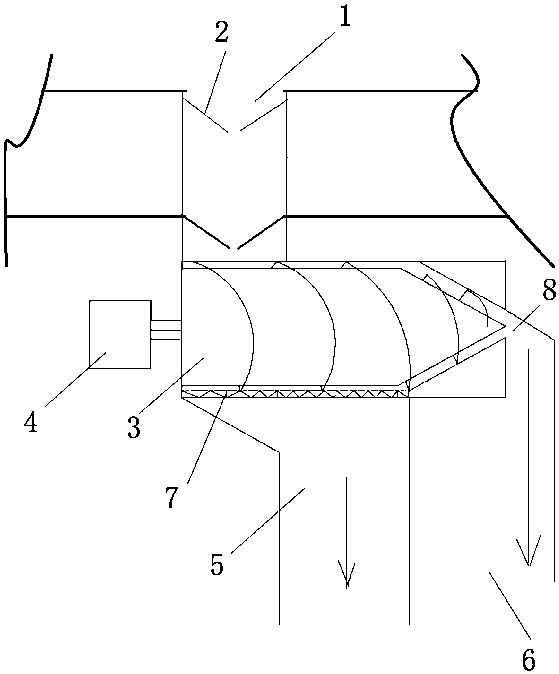

[0017] A residue pressing water tank, the bottom of the notch 1 is connected to the pressing chamber, and a number of picks 2 with springs are arranged in the notch 1, and a stainless steel screw 3 driven by a motor 4 is placed horizontally in the pressing chamber, and the thread pitch of the screw 3 is gradually reduced .

[0018] The bottom of the screw 3 is provided with a filter screen 7 connected to the drain pipe 5, the end of the screw rod 3 is conical, and the slag discharge port 8 is connected to the slag discharge pipe 6 and is higher than the filter screen 7; the surface of the water tank is provided with a motor 4 control key.

[0019] When in use, waste food residues are poured into the notch 1, the plectrum 2 is opened downward under pressure, and the residues fall into the pressing chamber. Start the motor 4 through the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com