Variable length connecting rod with hydraulic mechanism

A hydraulic mechanism and connecting rod technology, which is applied in the direction of connecting rods, mechanical equipment, machines/engines, etc., can solve problems such as knocking in high-load areas, and achieve the effects of high feasibility, simple structure, and improved thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The preferred technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

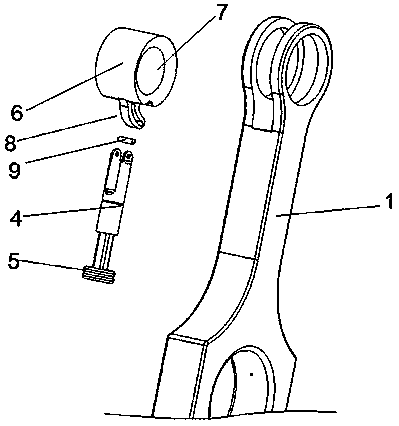

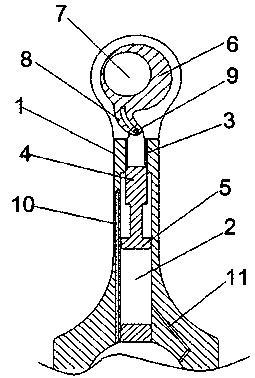

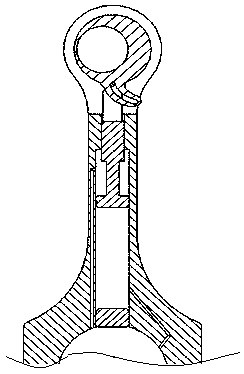

[0016] Such as figure 1 As shown, a variable-length connecting rod with a hydraulic mechanism of the present invention, in order to prevent engine knocking, produce a larger or smaller compression ratio, that is, to avoid damage to other parts caused by changes in the thrust of the previous push connecting rod, A variable-length connecting rod is provided, which also has a hydraulic buffer function under the instantaneous powerful driving force of the engine piston, and mainly includes a connecting rod 1, and the rod body of the connecting rod 1 is a cavity 2, Cavity 2 leads to connecting rod small end and has piston pipe 3, and piston pipe 3 is provided with piston rod 4, and described piston rod 4 has piston body 5 towards the big end of connecting rod, and piston body 5 moves in cavity 2, so The small head of the connecting ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com