Control method of air cooling screw heat pump system

A technology of heat pump system and air-cooled screw, which is applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., and can solve the problems of complex operation and single operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

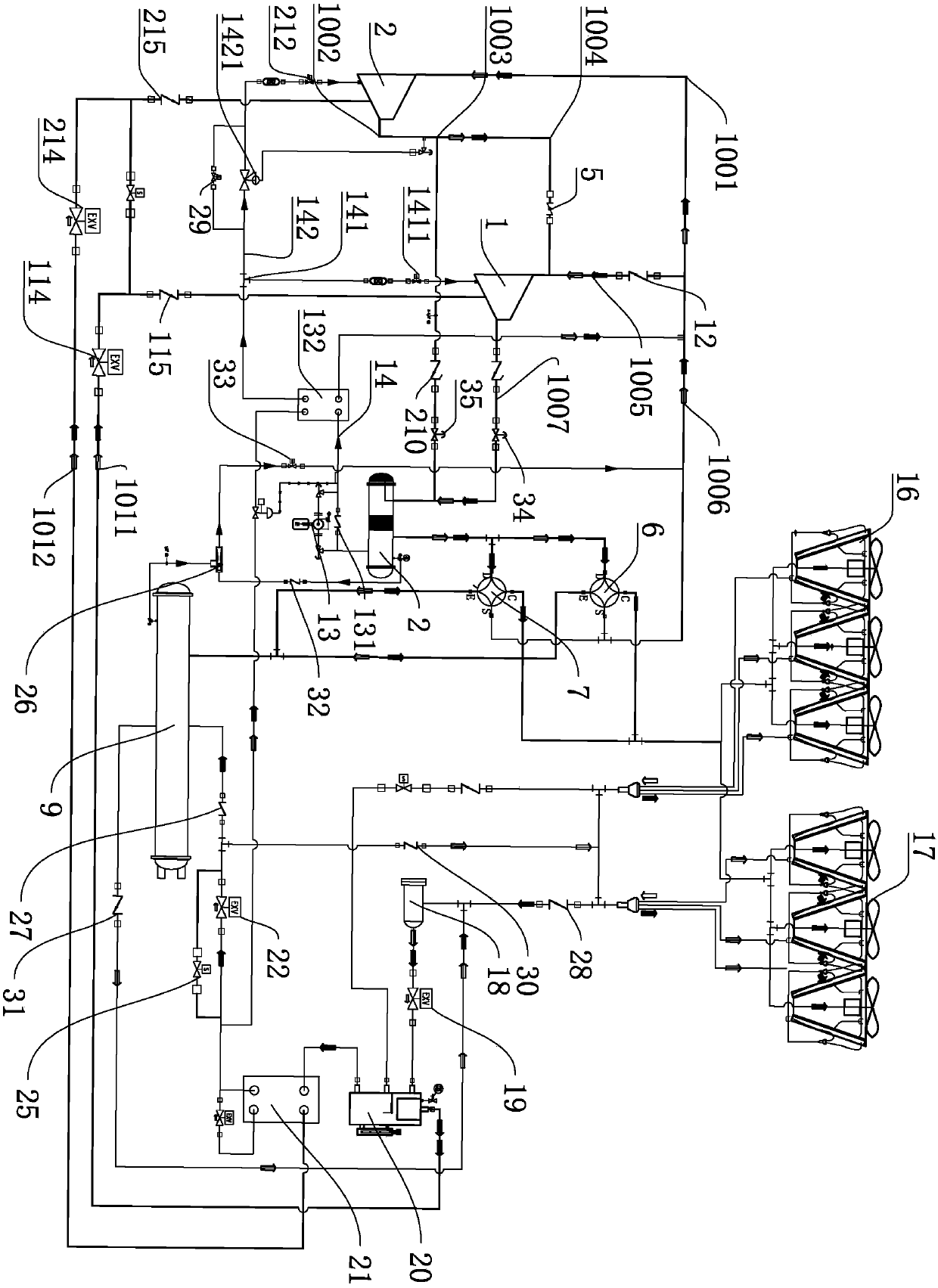

[0021] Embodiment 1: A control method for an air-cooled screw heat pump system:

[0022]

[0023]

[0024]

[0025]

[0026] The key to two-stage compression control is how to effectively control the intermediate pressure, that is, to reasonably match and control the load percentage of the high pressure stage and the first compressor to keep the intermediate pressure stable.

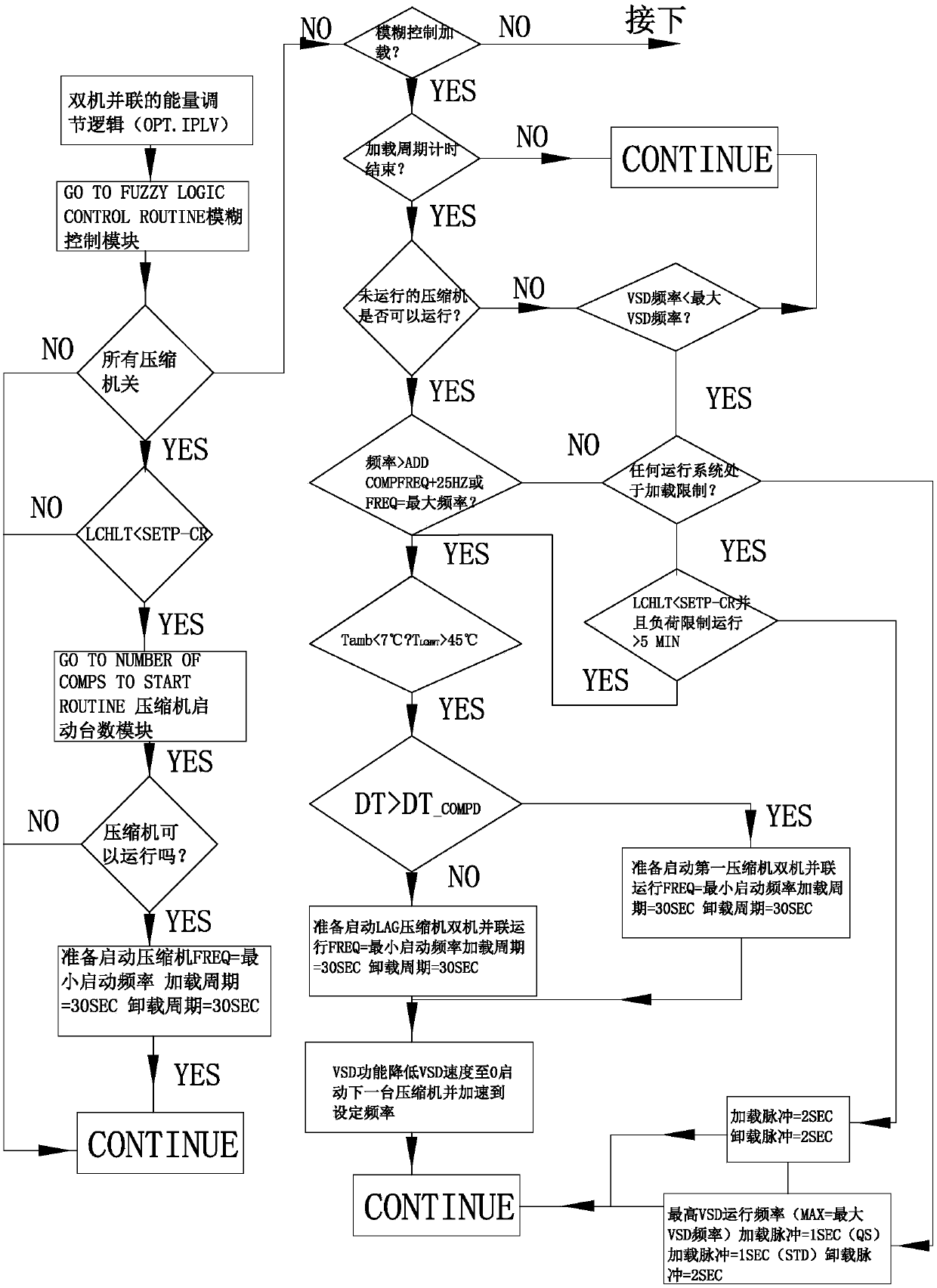

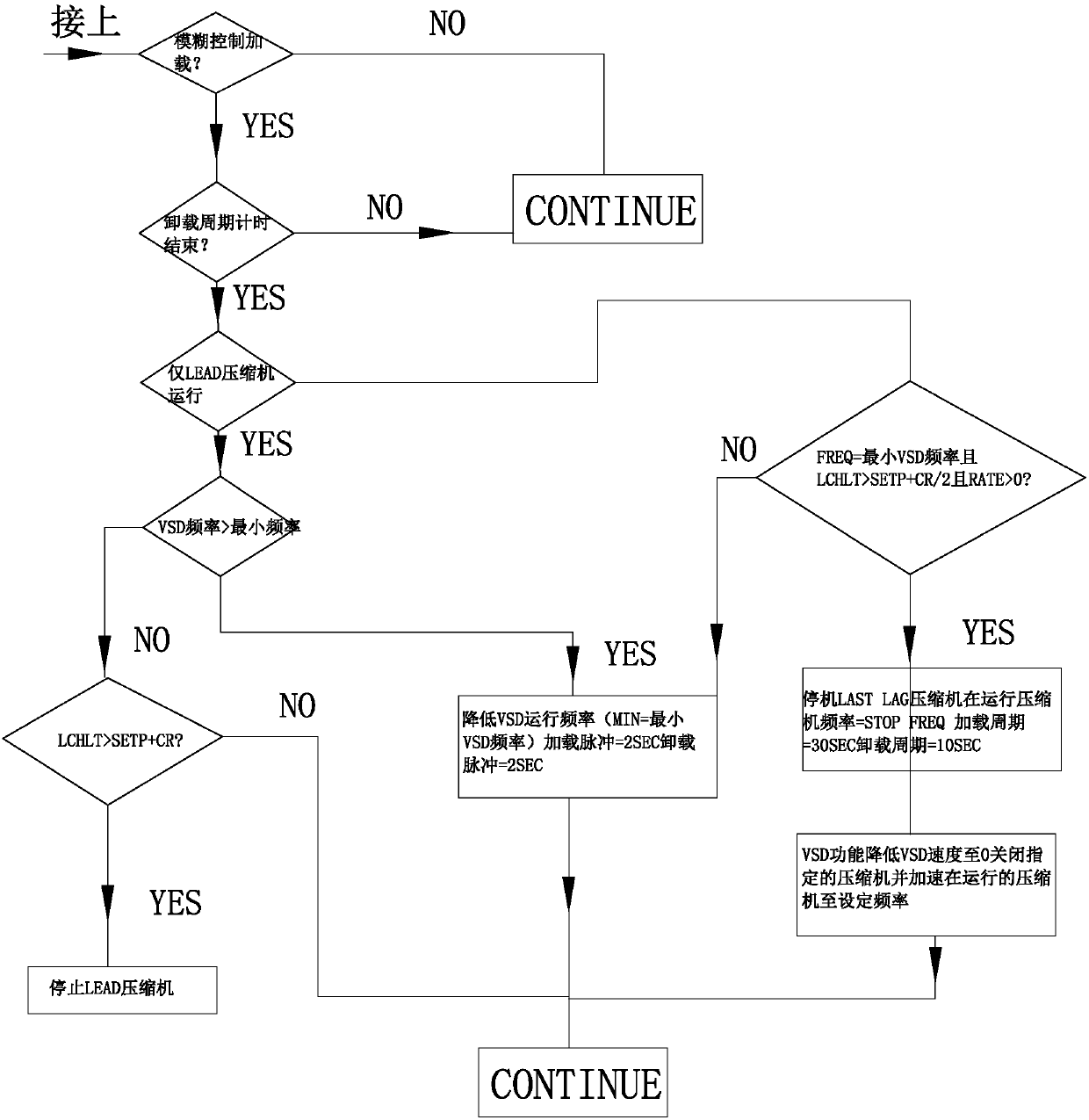

[0027] In the initial stage of startup, either the first compressor 101 or the second compressor 102 must be started. Generally, the second compressor 102 is set as the lead system, and the first compressor 101 is the lag system; when starting, the lead compressor Priority to start, and priority to shut down the lag compressor when it is stopped. Adjustable control and switch logic, down figure 2 Shown is the energy control logic for tandem and two-stage units. Down image 3 Described is the action control of various valves when switching between the single-machine operation mode and the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap