A Measuring Method for Material Flow of Screw Conveyor

The technology of a screw conveyor and a measurement method is applied in the field of measurement, which can solve the problems of grain influence, radioactivity, and inability to effectively reflect grain yield information, etc., and achieve the effect of improving measurement accuracy and high precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in combination with specific embodiments.

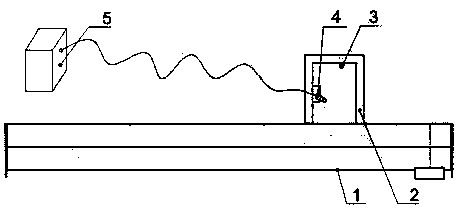

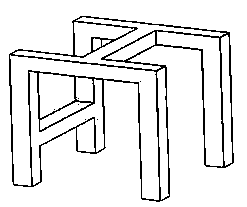

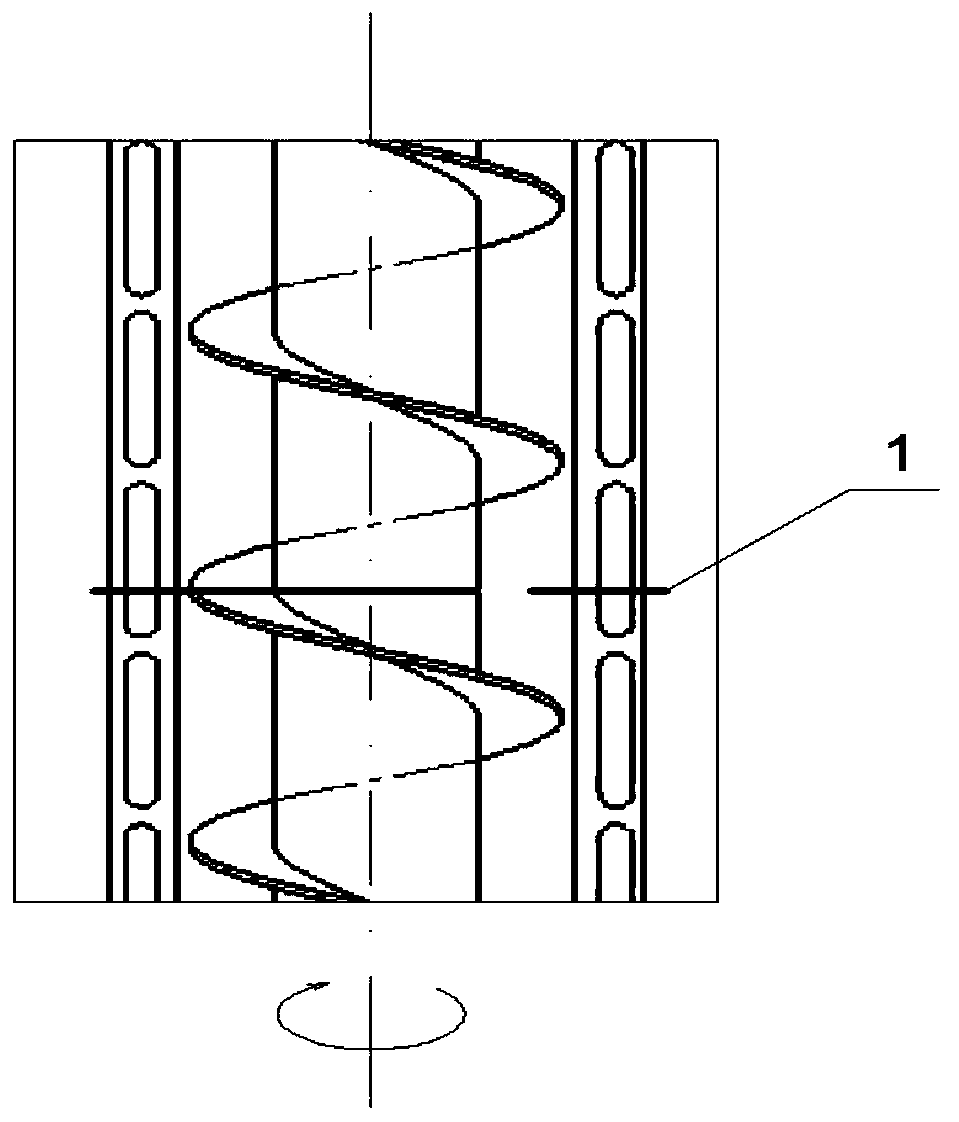

[0022] The present invention uses the laser triangulation method to measure the volume of the grain transported by the screw conveyor in real time; figure 1 A measuring system for the material flow rate of a screw conveyor is shown, including a screw conveyor 1, a measuring platform 2 is mounted on the screw conveyor 1, and a laser 3 and an industrial camera 4 are installed on the measuring platform 2. The laser is connected to a power supply, and the industrial camera 4 is connected to the microcomputer system 5; the assembly relationship of each part is as follows, the industrial camera 4 and the laser 3 are assembled on the measuring table according to the laser triangulation method figure 2 superior. Such as image 3 The laser 3 irradiates the screw blades in the screw conveyor vertically, and the irradiation position is on the side close to the discharge port; whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com