Railway vehicle rolling vibration test bench curve passage testing method

A technology of a railway vehicle and a test method, applied in the field of machinery, can solve the problems of inability to carry out, large impact, small wheel-rail attack angle, etc., and achieve the effect of a good test environment and reliable analysis data.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0056] Below in conjunction with example the present invention is described in further detail.

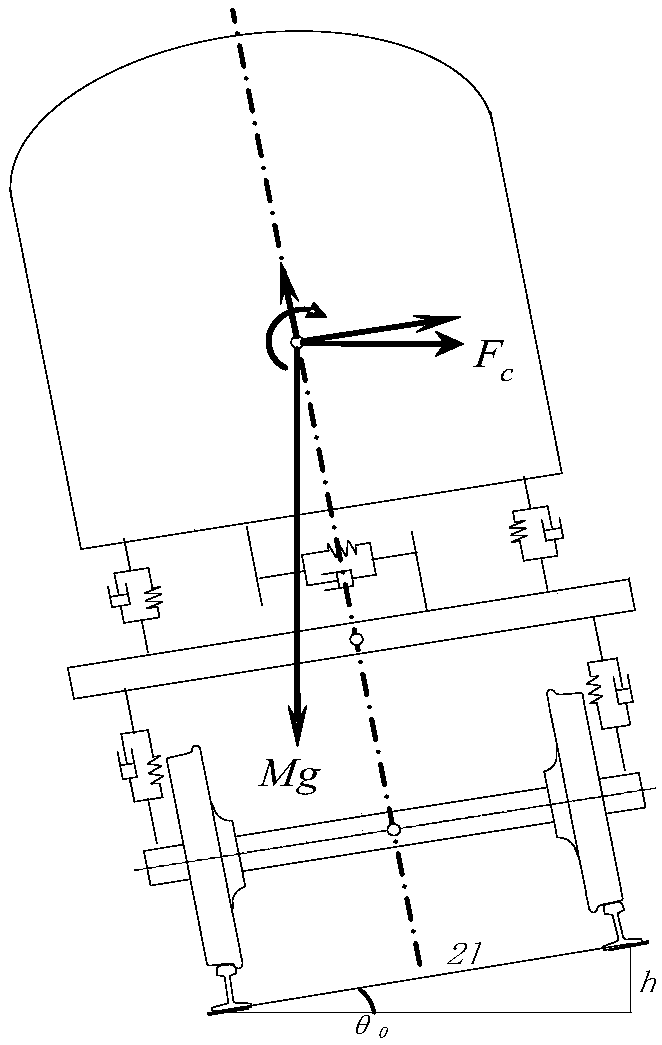

[0057] A railway vehicle rolling vibration test bench curve passing test method, the steps are:

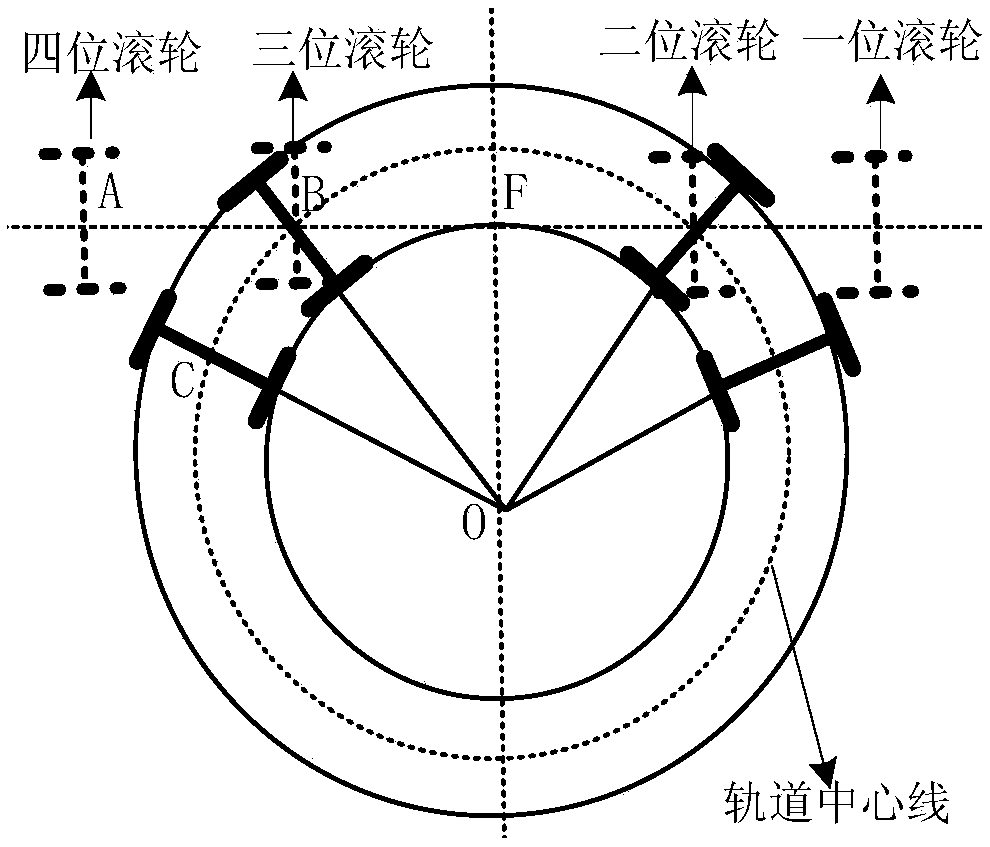

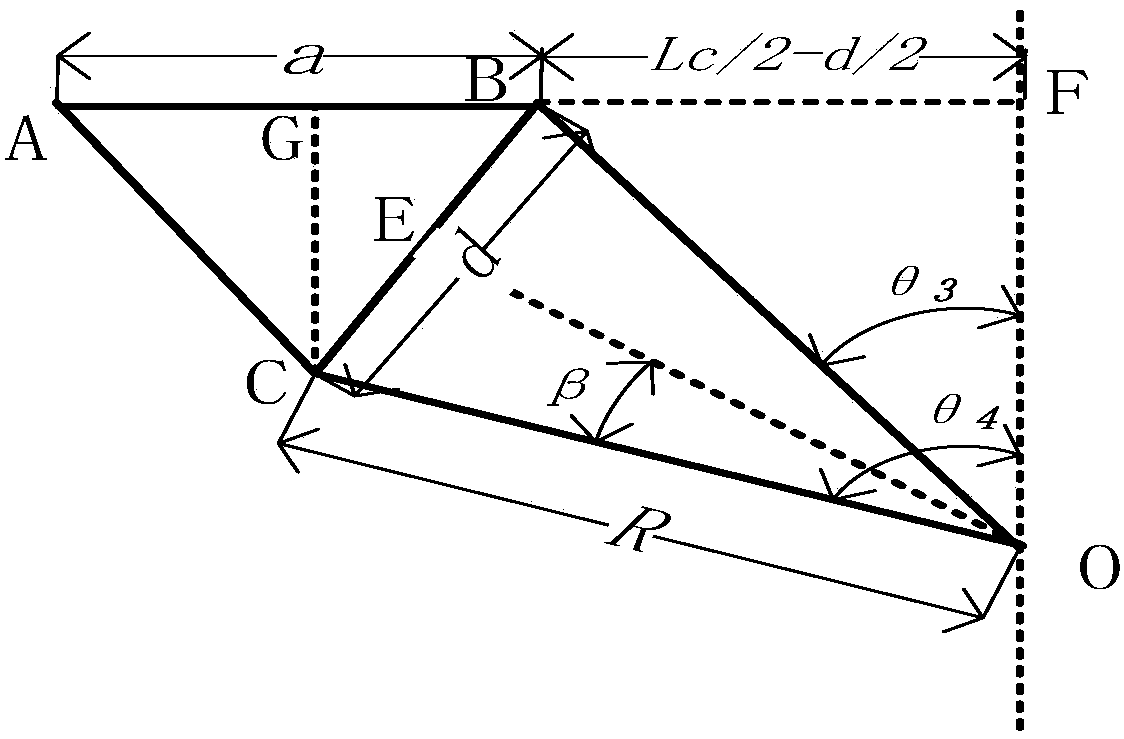

[0058]A. Simulation of the length difference between the inner and outer rails of the curve

[0059] When the vehicle passes through a curved line with a certain radius, the outer rail of the line is longer than the inner rail, and the rolling table adjusts the rotation speed of the rolling vibration wheel to make the speed difference between the rolling vibration wheels on both sides, so that the left and right wheels have different rolling distances in the same time, that is, Simulate the difference in the length of the inner and outer rails on the curve.

[0060] If the curve is right-curved, the radius of the curve is R, the gauge is 2l, the speed of the wheel passing through the curve is V, and the speed of the outer wheel is V l , inside wheel speed V r , angular velocity ω of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com