Organic light-emitting diode (OLED) display device and fabrication method thereof

A display device and electrode technology, which is applied in the manufacture of semiconductor/solid-state devices, electrical components, and electrical solid-state devices, etc., can solve the problems of organic layer damage, easy to cause microcavity effect, and unfavorable device performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

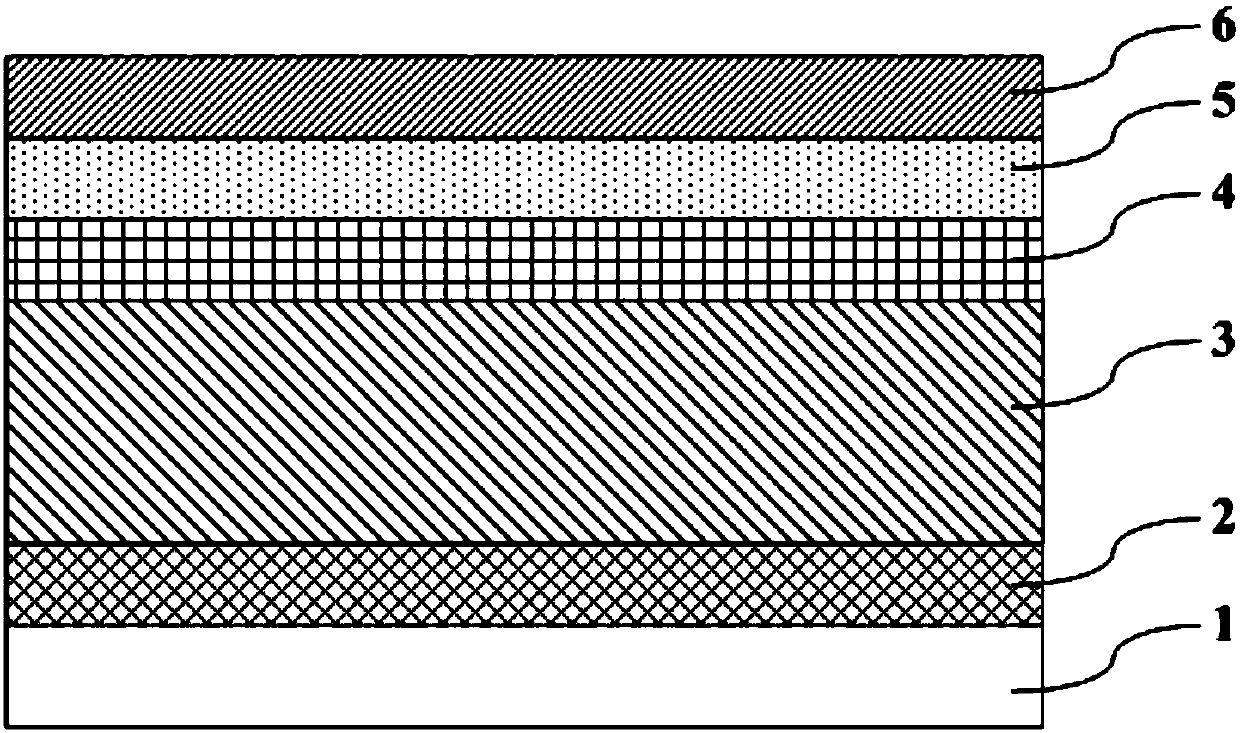

[0040] The present invention provides an OLED display device, such as figure 1 As shown, the OLED display device includes a base substrate 1, a first electrode 2, an organic functional layer 3, a second electrode 4, a polymer dispersed liquid crystal layer 5, and an upper electrode 6 stacked in sequence, wherein the first electrode 2 is opaque electrode, the second electrode 4 is a translucent electrode. Wherein, the first electrode 2, the organic functional layer 3 and the second electrode 4 form a microcavity structure, forming a microcavity effect; when the OLED display device is working, the absolute value of the voltage difference between the first electrode 2 and the second electrode 4 is 0 (that is, the electric field strength between the first electrode 2 and the second electrode 4 is 0) or greater than 0. The OLED display device is a top emission type OLED display device.

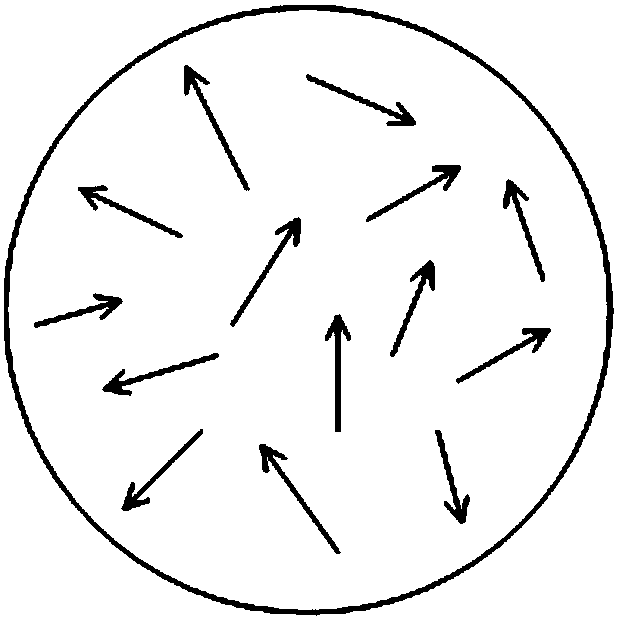

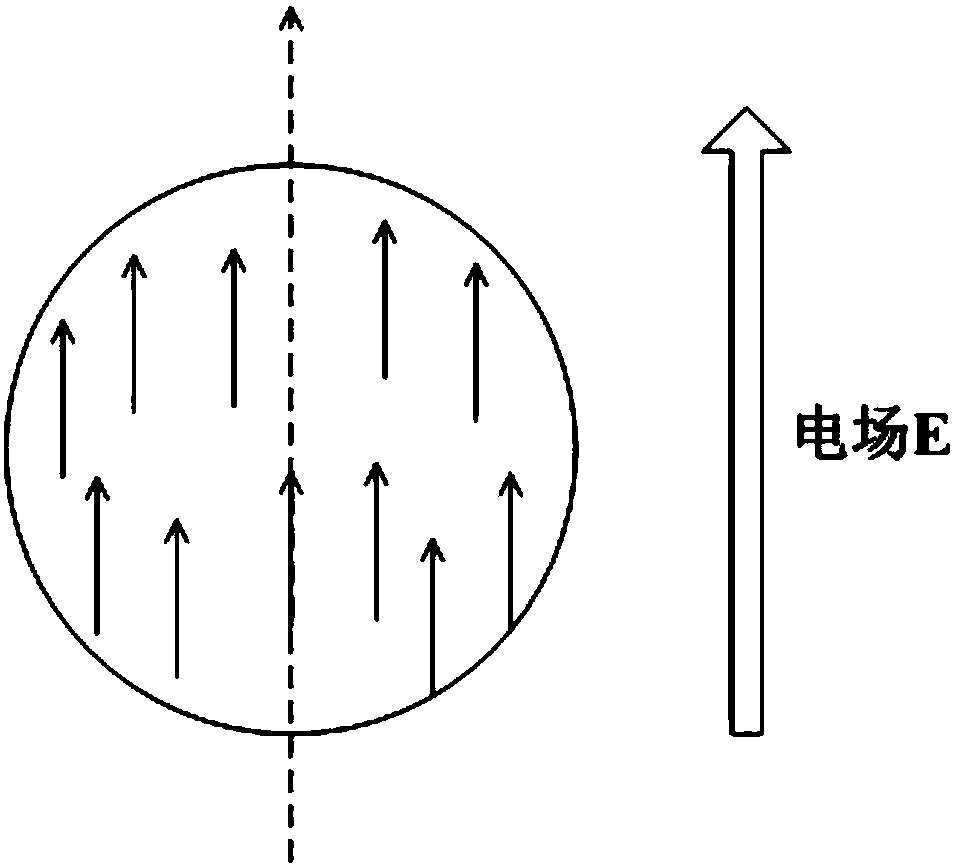

[0041] Polymer Dispersed Liquid Crystal (PDLC, Ploymer Dispersed Liquid Crystal) is one of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com