Anion integrated hot plate

A technology that integrates electric heating and negative ions, applied in the direction of electric heating devices, ohmic resistance heating, ohmic resistance heating parts, etc., can solve the problems of unsustainable purification effect, poor purification effect, expensive price, etc., and achieve long-lasting and long-lasting purification effect Good, the effect of improving the interface properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

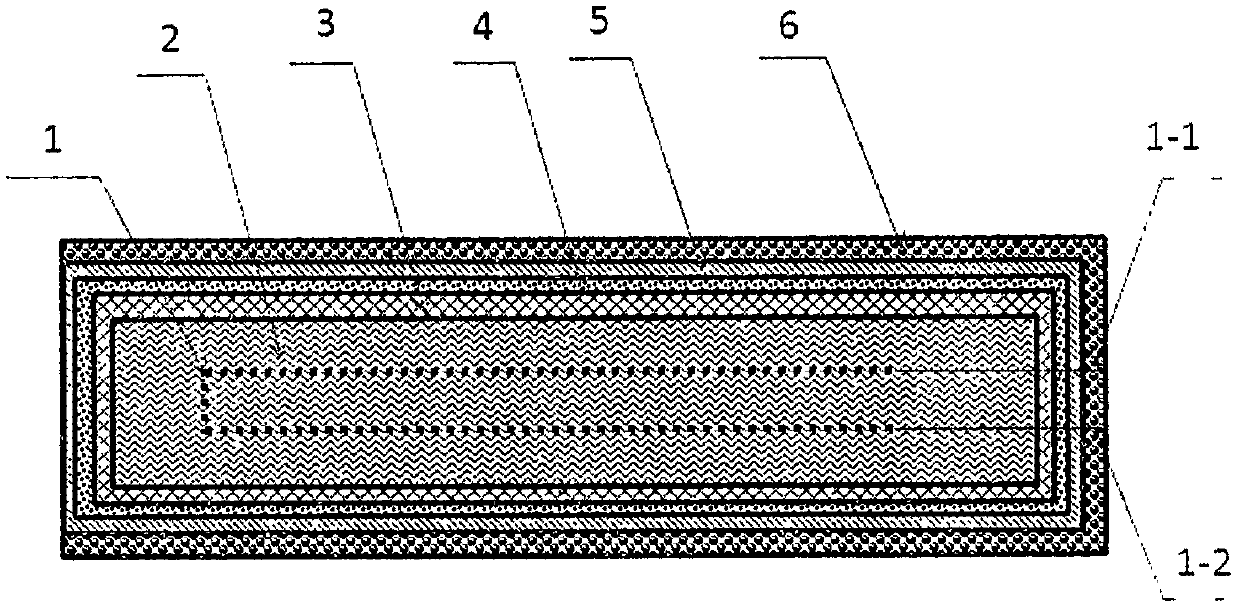

[0054] to combine figure 1 , an anion-integrated electric heating plate, comprising, a heating element 1, an insulating layer 2, a thermal insulation layer 3, a moisture-proof layer 4, a heat dissipation substrate layer 5, and a UV varnish layer 6 containing tourmaline particles; wherein, the heating element 1 Wrapped in the insulation layer 2, and evenly arranged in the insulation layer; the outside of the insulation layer 2 is wrapped with an insulation layer 3, the outside of the insulation layer is wrapped with a moisture-proof layer 4, and the outside of the moisture-proof layer 4 is wrapped with a heat dissipation layer Substrate layer 5, the outer surface of the heat dissipation substrate layer 5 is coated with a UV varnish layer 6 containing tourmaline particles; one end of the heating element 1 is connected to the first external lead 1-1 of the heating element, and the other end is connected to the heating element. The second external lead wire 1-2 of the element, the...

Embodiment 2

[0056] to combine figure 1 , a negative ion integrated electric heating plate capable of reducing indoor PM2.5 in this embodiment; including heating element 1, insulating layer 2, heat preservation layer 3, moisture-proof layer 4, heat dissipation substrate layer 5 and UV light containing tourmaline particles Oil layer 6; wherein, the heating element 1 is wrapped in the insulating layer 2, and is evenly arranged in the insulating layer; the insulating layer 2 is wrapped with an insulating layer 3, and the insulating layer is wrapped with a moisture-proof layer 4 , the outer surface of the moisture-proof layer 4 is wrapped with a heat-dissipating base material layer 5, and the outer surface of the heat-dissipating base material layer 5 is coated with a UV varnish layer 6 containing tourmaline particles; one end of the heating element 1 is connected to the second heating element An external lead wire 1-1, the other end of which is connected to the second external lead wire 1-2 o...

Embodiment 3

[0062] A preparation method for anion-integrated electric heating plate, comprising the steps of:

[0063] Step (1), assembling the heating element 1, the insulation layer 2, the heat preservation layer 3, the moisture-proof layer 4, and the heat dissipation substrate layer 5 to form an electric heating plate;

[0064] Step (2), prepare the functional UV varnish coating that contains tourmaline superfine powder,

[0065] Wherein, described functional UV varnish paint comprises UV varnish; The particle diameter of tourmaline superfine powder is 4000 orders; Calculate with the total mass of functional UV varnish paint, the massfraction of tourmaline superfine powder is 8 %;

[0066] (3), the functional UV varnish coating prepared by step (2) is uniformly coated on the heat dissipation substrate layer 5 of the electric heating plate of step (1), and after curing, a UV varnish layer with tourmaline particles is formed, and UV varnish layer is formed. The thickness of the varnish...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com