Large-format multi-laser interface scanning method based on powder bed additive manufacturing

A technology of additive manufacturing and laser scanning, which is applied in the direction of additive manufacturing, additive processing, and improvement of process efficiency, can solve the problems of poor forming effect in the edge area, difficulty in coordinated control of the f-θ focusing system, and lack of elaboration, etc., to achieve The effect of ensuring tissue uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

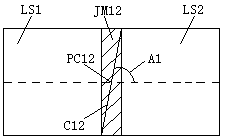

[0041] Such as Figure 1-4 As shown, the large-format multi-laser interface scanning method based on powder bed additive manufacturing includes the following steps:

[0042] The first step is to divide the large-format dual-laser working surface based on powder bed additive manufacturing;

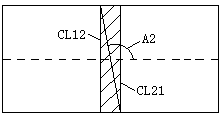

[0043] In the second step, the diagonal C12 is rotated around the center point PC12, and the rotation angle changes with the number of model layers;

[0044] In the third step, the 3D model of the parts is sliced and layered according to the layer thickness parameters required by the laser selective melting additive manufacturing process, and each layer is numbered.

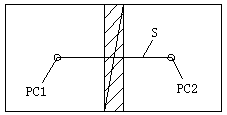

[0045] Among them, the area division includes that the scanning range of the laser scanning heads LS1 and LS2 is a square area with a side length D, the center points of the laser scanning heads LS1 and LS2 are respectively PC1 and PC2, and the distance between the two points of PC1 and PC2 is S, The overlapping area is JM...

Embodiment 2

[0057] Such as Figure 1-4 As shown, the large-format multi-laser interface scanning method based on powder bed additive manufacturing includes the following steps:

[0058] The first step is to divide the large-format dual-laser working surface based on powder bed additive manufacturing;

[0059] In the second step, the diagonal C12 is rotated around the center point PC12, and the rotation angle changes with the number of model layers;

[0060] In the third step, the 3D model of the parts is sliced and layered according to the layer thickness parameters required by the laser selective melting additive manufacturing process, and each layer is numbered.

[0061] Among them, the area division includes that the scanning range of the laser scanning heads LS1 and LS2 is a square area, the center points of the laser scanning heads LS1 and LS2 are respectively PC1 and PC2, the distance between the two points of PC1 and PC2 is S, and the overlapping area is JM12 And JM12 is a rect...

Embodiment 3

[0072] Such as Figure 1-4 As shown, the large-format multi-laser interface scanning method based on powder bed additive manufacturing includes the following steps:

[0073] The first step is to divide the large-format dual-laser working surface based on powder bed additive manufacturing;

[0074] In the second step, the diagonal C12 rotates around the center point PC12, and the rotation angle changes with the number of model layers;

[0075] In the third step, the 3D model of the parts is sliced and layered according to the layer thickness parameters required by the laser selective melting additive manufacturing process, and each layer is numbered.

[0076] Among them, the area division includes that the scanning range of the laser scanning heads LS1 and LS2 is a square area, the center points of the laser scanning heads LS1 and LS2 are respectively PC1 and PC2, the distance between the two points of PC1 and PC2 is S, and the overlapping area is JM12 And JM12 is a rectang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com