Improved honeycomb core veneer adopting hexagonal structure and forming method of improved honeycomb core veneer

A forming method, hexagonal technology, applied in the field of improving the hexagonal honeycomb core plate and its forming, can solve the problems such as the difficulty of making great breakthroughs in compressive strength, restricting the scope of application, etc., and save glue application time , expanding the scope of application, the effect of little environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

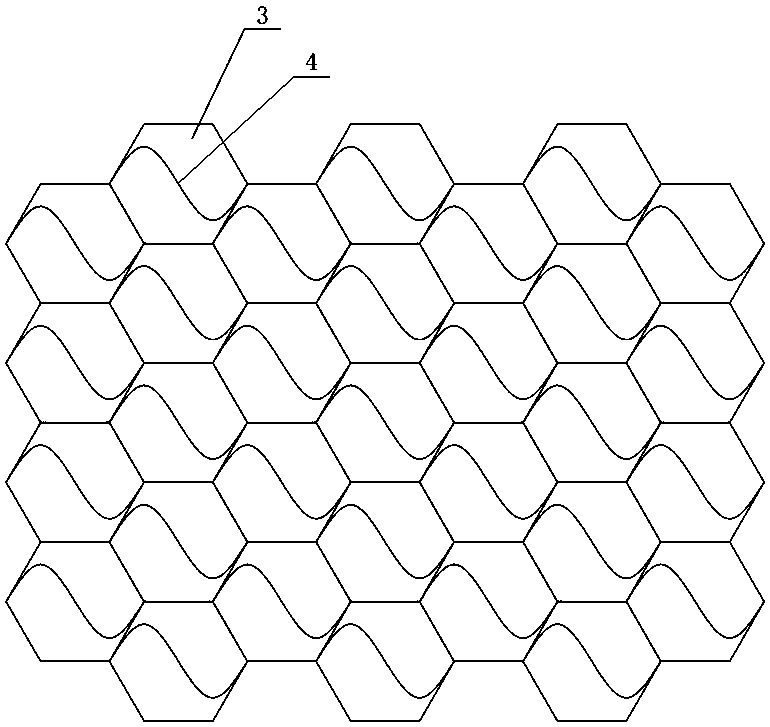

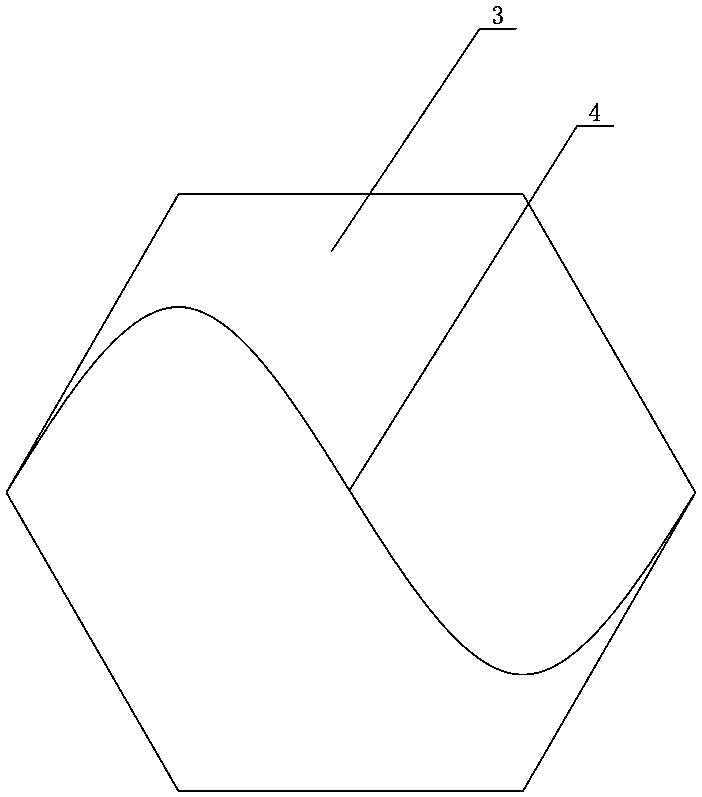

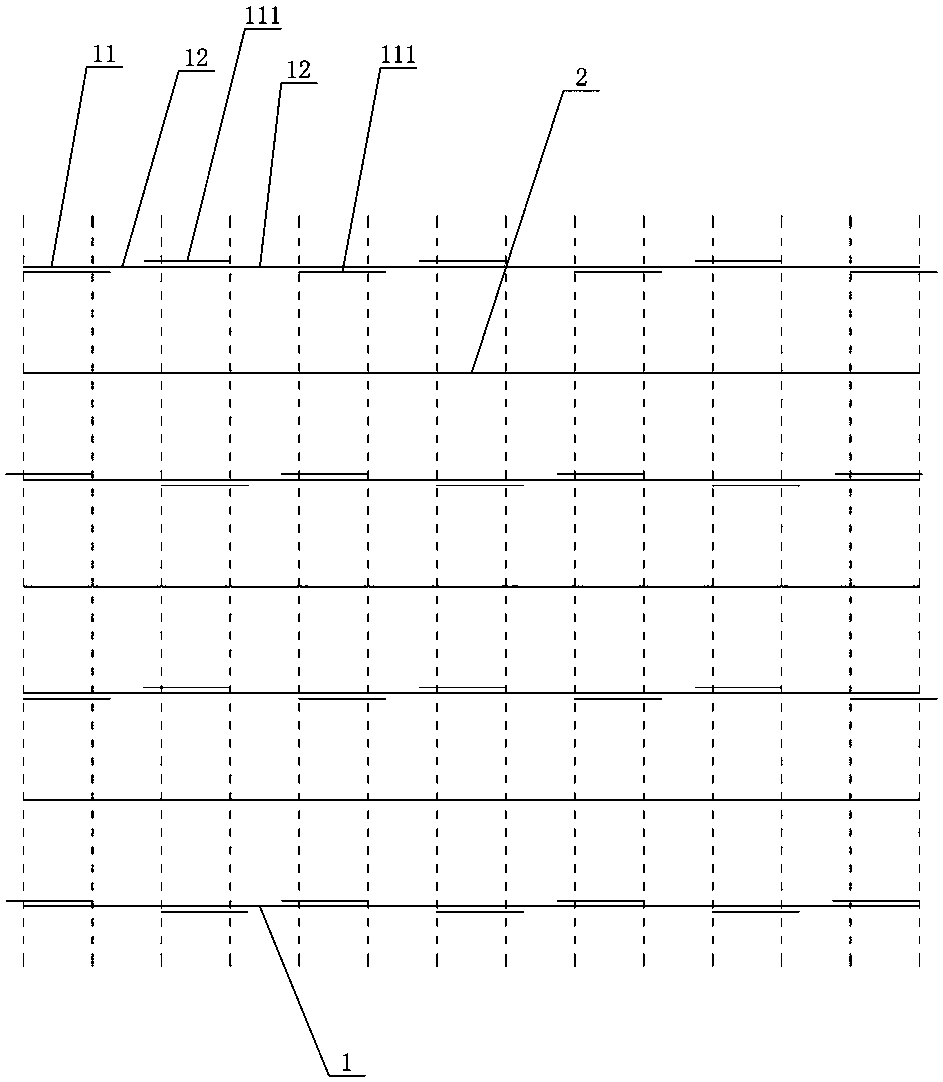

[0029] Figure 1 to Figure 4 It shows an embodiment of the honeycomb core plate with improved hexagonal structure in the present invention, including at least two original base bands 1, a reinforcing band 2 is arranged between each original base band 1, and the original base bands 1 are evenly spaced and divided into A plurality of bonding edges 11, a molding edge 12 is divided between two adjacent bonding edges 11, one side of the bonding edge 11 of the odd bonding position and the other side of the bonding edge 11 of the even bonding position Adhesive areas 111 are provided on the side, and each adhesive area 111 extends to the adjacent molding edge 12 in the same direction. The two sides are bonded to the corresponding bonding areas 111 and pulled apart to form a honeycomb structure with a plurality of hexagonal unit holes 3. Each...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap