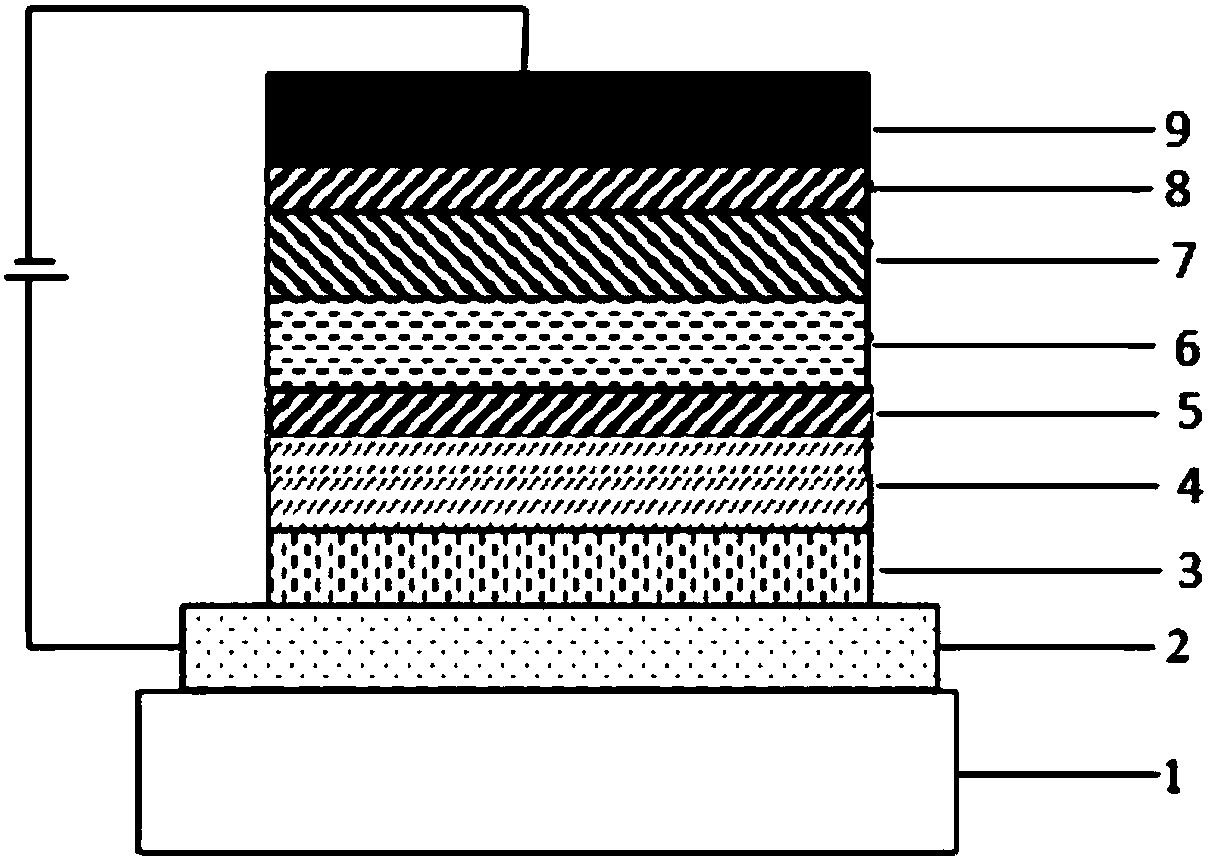

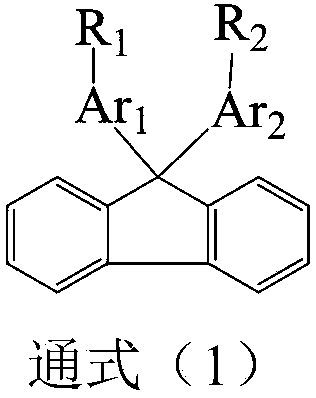

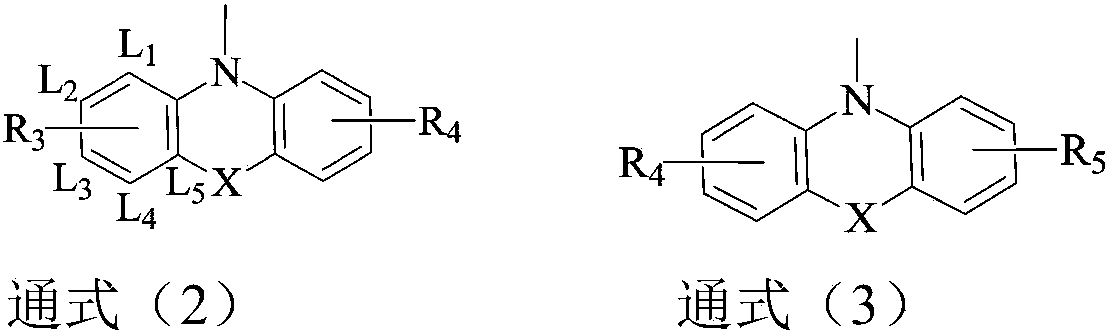

Fluorene-containing organic compound as well as preparation method and application thereof in OLED (organic light emitting diode) device

A technology of organic compounds and bromides, applied in the field of organic optoelectronic materials, can solve different problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0145] Embodiment 1: the synthesis of compound 1:

[0146] synthetic route:

[0147]

[0148] In a 250ml three-neck flask, under the protection of nitrogen, add 0.01mol raw material A1, 0.012mol raw material B1, 150ml toluene and stir to mix, then add 5×10 -5 mol Pd 2 (dba) 3 , 5×10 -5 mol of tri-tert-butylphosphine, 0.03mol of sodium tert-butoxide, heated to 105°C, refluxed for 24 hours, sampling plate, showed no remaining bromide, and the reaction was complete; naturally cooled to room temperature, filtered, and the filtrate was rotary evaporated until there was no distillate , through a neutral silica gel column to obtain the target product, with a HPLC purity of 99.1% and a yield of 67.3%;

[0149] Elemental analysis structure (molecular formula C 64 h 54 N 2 ): theoretical value C, 90.31; H, 6.39; N, 3.29; test value: C, 90.31; H, 6.36; N, 3.33.

[0150] HPLC-MS: The molecular weight of the material is 850.43, and the measured molecular weight is 850.49.

Embodiment 2

[0151] Embodiment 2: the synthesis of compound 5:

[0152] synthetic route:

[0153]

[0154] In a 250ml three-neck flask, under the protection of nitrogen, add 0.01mol raw material A1, 0.012mol raw material B2, 150ml toluene and stir to mix, then add 5×10 -5 mol Pd 2 (dba) 3 , 5×10 -5 mol of tri-tert-butylphosphine, 0.03mol of sodium tert-butoxide, heated to 105°C, refluxed for 24 hours, sampling plate, showed no remaining bromide, and the reaction was complete; naturally cooled to room temperature, filtered, and the filtrate was rotary evaporated until there was no distillate , through a neutral silica gel column to obtain the target product, with a HPLC purity of 99.1% and a yield of 66.8%;

[0155] Elemental analysis structure (molecular formula C 58 h 40 N 2 O): Theoretical value C, 89.20; H, 5.16; N, 3.59; O, 2.05; Test value: C, 89.3; H, 5.15; N, 3.61.

[0156] HPLC-MS: The molecular weight of the material is 780.31, and the measured molecular weight is 780.6...

Embodiment 3

[0157] Embodiment 3: the synthesis of compound 11:

[0158] synthetic route:

[0159]

[0160] In a 250ml three-neck flask, under the protection of nitrogen, add 0.01mol raw material A1, 0.012mol raw material B3, 150ml toluene and stir to mix, then add 5×10 -5 mol Pd 2 (dba) 3 , 5×10 -5 mol of tri-tert-butylphosphine, 0.03mol of sodium tert-butoxide, heated to 105°C, refluxed for 24 hours, sampling plate, showed no remaining bromide, and the reaction was complete; naturally cooled to room temperature, filtered, and the filtrate was rotary evaporated until there was no distillate , through a neutral silica gel column to obtain the target product, with a HPLC purity of 99.3% and a yield of 62.7%;

[0161] Elemental analysis structure (molecular formula C 58 h 40 N 2 O): theoretical value C, 89.20; H, 5.16; N, 3.59; O, 2.05; test value: C, 89.21; H, 5.15; N, 3.59;

[0162] HPLC-MS: The molecular weight of the material is 780.31, and the measured molecular weight is 780...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com