Automatic workover rig

A workover rig, automatic technology, applied in drilling equipment, earthwork drilling, drill pipe and other directions, can solve the problems of high labor intensity, high operation risk, harsh operating environment, etc., to reduce labor intensity, reduce safety hazards, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing, the present invention is described in detail.

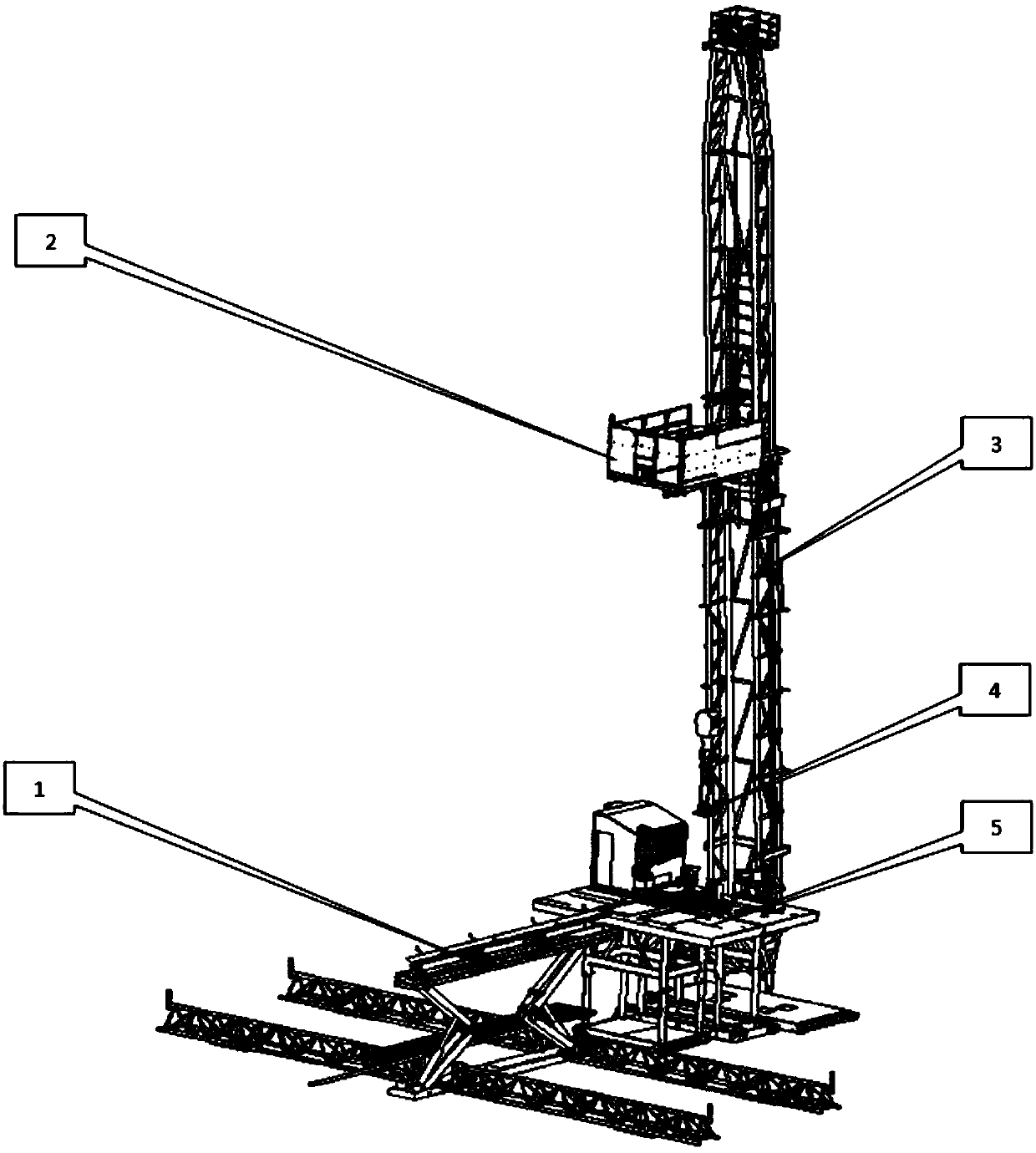

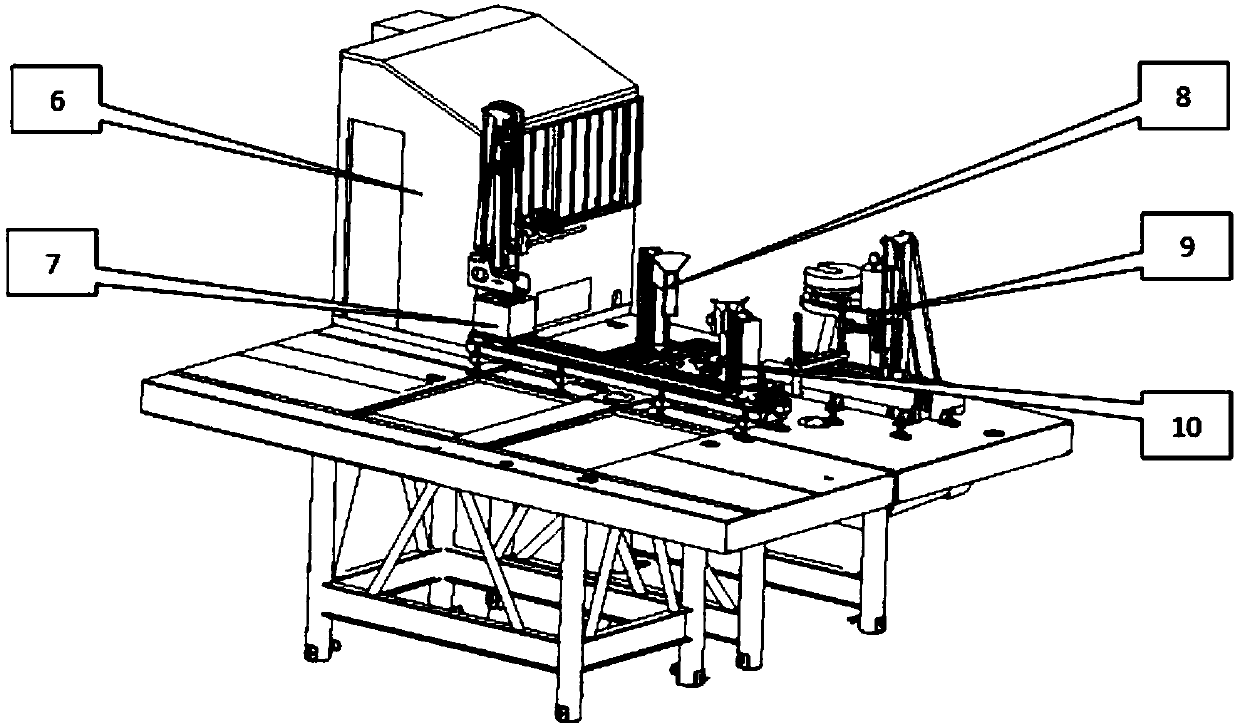

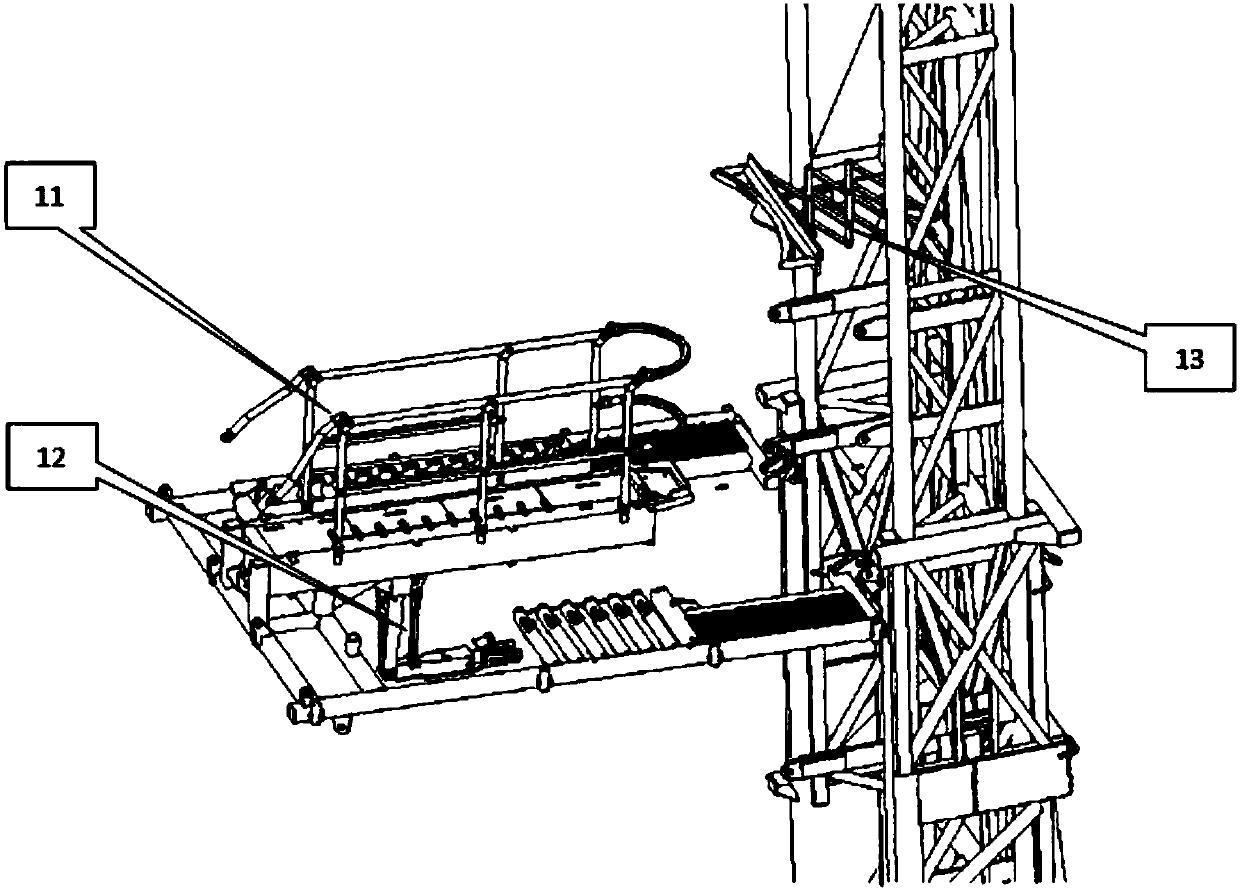

[0030] Such as figure 1 , figure 2 and image 3 As shown, the present invention includes a drilling tool conveying device 1, a second floor platform 2, a derrick 3, an automatic elevator 4, a drill floor 5, a driller's room 6, a drill floor manipulator 7, a drill pipe make-up centering device 8, and a drill floor surface. Automatic hydraulic tongs 9, automatic slips 10, folding railings 11 of the second-story platform, manipulator 12 of the second-story platform, anti-shake device 13 for traveling vehicle and lifting ring, control system, etc.

[0031] Such as Figure 4 , Figure 5 , Figure 6 and Figure 7As shown, the drilling tool conveying device 1 includes a drill pipe rack 14, a retaining pile 15, a guide rail 16, a drill pipe shift fork 17, a telescopic block 18, a V-shaped groove 19, a kelly lifting block 20, a lifting connecting rod 21, Hydraulic cylinder 22,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com