Carbon-fiber composite-material super antimagnetic watch and manufacturing method

A composite material and carbon fiber technology, applied in the field of watches, can solve the problems of increasing the thickness of the carbon fiber watch case, the carbon fiber composite material is not dense enough, and cannot meet the super anti-magnetic properties, etc., and achieves the effect of light weight, thin appearance and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

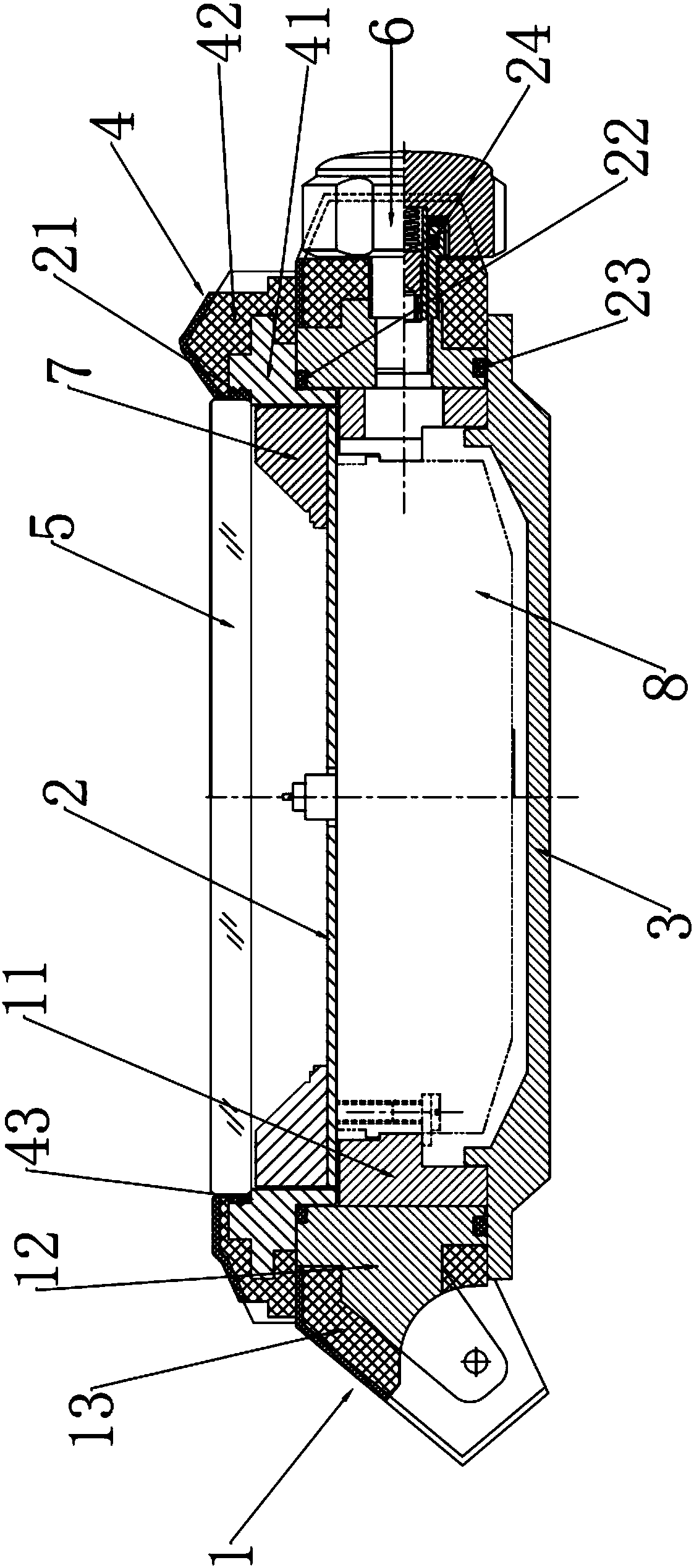

[0044] Such as figure 1As shown, the embodiment of the present invention provides a carbon fiber composite material super antimagnetic watch applicable to aerospace, which adopts a lightweight design and has an antimagnetic and waterproof function. The super strong antimagnetic watch made of carbon fiber composite material comprises a case 1, a dial 2, an antimagnetic bottom cover or bottom cover 3, a bezel 4, a watch glass 5, a handle 6, an inner shadow ring 7 and a movement 8. The watch case 1 includes an antimagnetic liner 11 distributed from the inside to the outside, a protective cover 12 and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturation magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com