Novel full-automatic multifunctional electric oven

A fully automatic and multi-functional technology, applied in the field of ovens, can solve problems such as single function, incomplete combustion of fuel, high cost, etc., achieve uniform baking temperature, solve energy waste, and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

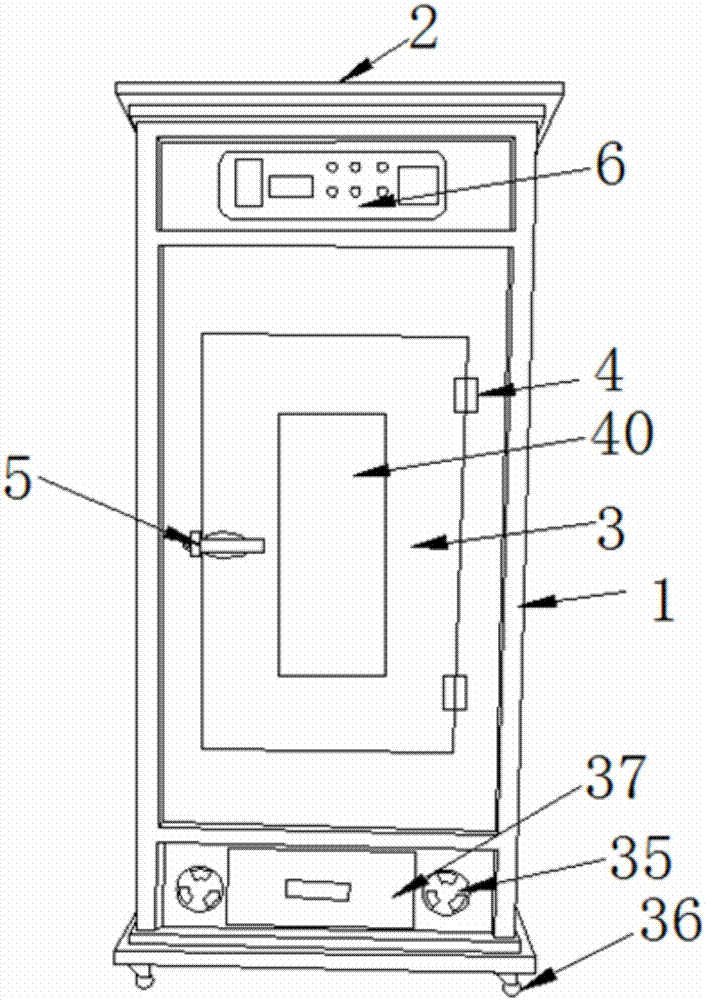

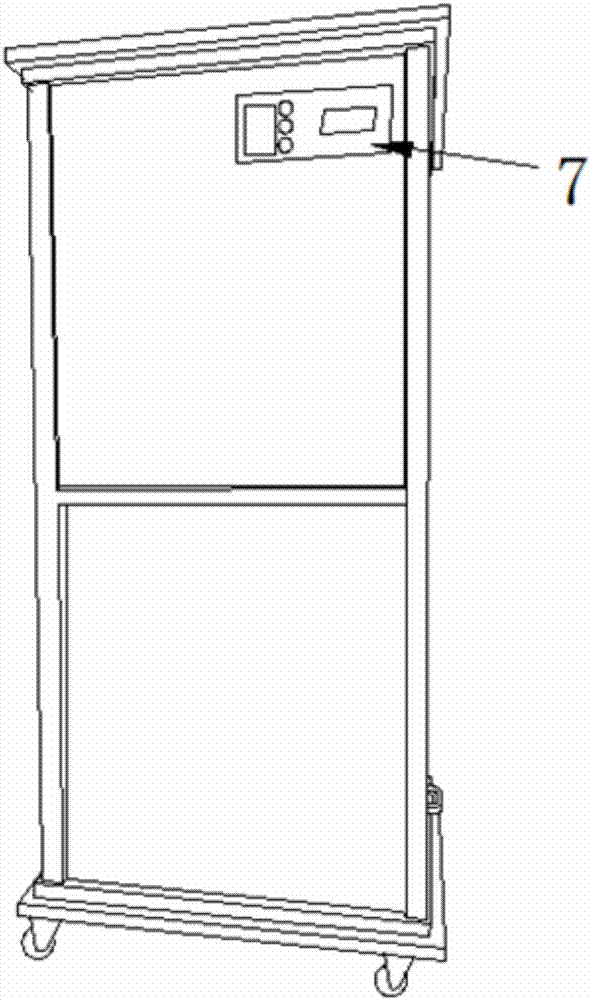

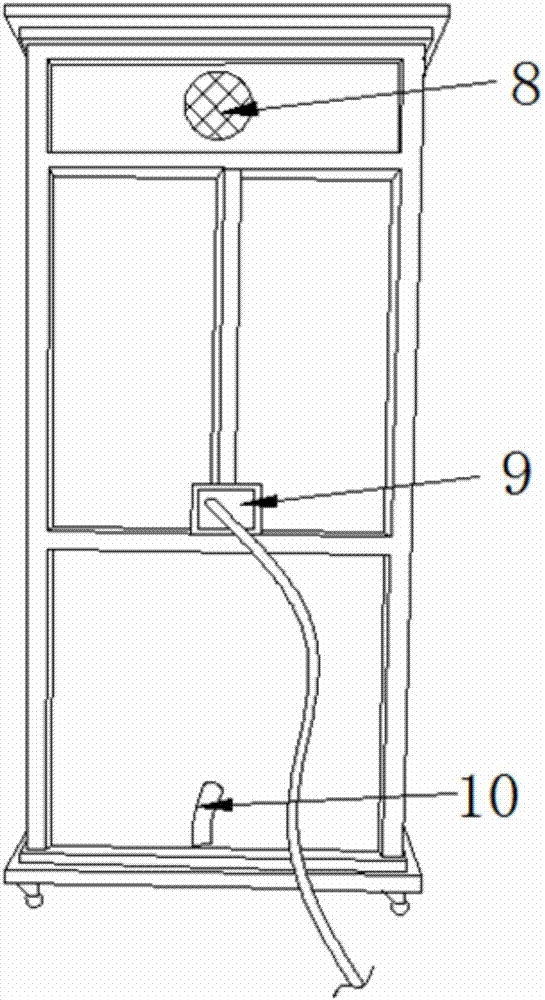

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

[0032] see as Figure 1-Figure 14 As shown, the technical solution adopted in this specific embodiment is: it includes a fuselage 1, an overhaul cover 2, a door leaf 3 of a roasting chamber, a hinge 4, a door handle 5, a main control panel 6, a side control panel 7, a power distribution Power junction box 9, drainage and oil discharge pipe 10, internal air supply cooling fan 11, octagonal grilling chamber 12, replaceable grill 13, U-shaped heating pipe 14, natural convection or forced convection exhaust hole 15, sewage discharge Inlet 16, porous convection partition 17, natural convection or forced convection air inlet 18, temperature sensor 20, partition 21, grease decomposition water tray 25, rotating motor 26, grilling chamber collection exhaust cylinder 27, curved air intake pipe 28. Bake room air supply duct 29, forced convection fan 30, braising room branch exha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com