Coating method of impact-resistant coating on the axle surface of crh5g EMU

A coating method and technology for EMUs, which are applied to devices, coatings, special surfaces and other directions for coating liquids on surfaces, can solve the problems of axle hits and the inability of anti-corrosion coatings to meet the operating requirements in sandy areas, and achieve shortened time. The effect of the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

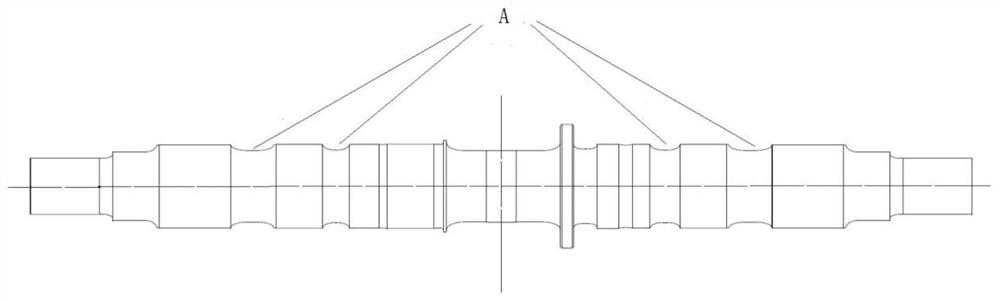

[0022] Specific implementation mode 1. Combination figure 1 Describe this embodiment, the coating method of the anti-strike coating on the surface of the CRH5G EMU axle, the specific process of the method is: axle surface cleaning, axle protection, axle spray area grinding, axle surface cleaning, tooling protection, primer spraying, axle , Tooling protection, topcoat spraying and demolition protection.

[0023] 1. Clean the surface of the axle. Use a cleaning paper dipped in acetone to clean the part of the axle to be sprayed until there is no stain on the surface of the cleaning paper. After wiping, the axle surface must be clean, dry, grease-free and metallic before grinding.

[0024] 2. Axle protection, use paper tape and plastic film to protect areas that do not need to be painted;

[0025] 3. Grinding the spraying area of the axle. Use 80# sandpaper to cross-grind the area to be sprayed on the axle. Shows an even sanded texture.

[0026] 4. Clean the surface of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com