Improved type laser welding processing work station

A laser welding and workstation technology, applied in laser welding equipment, welding equipment, welding equipment and other directions, can solve the problems of small and inconvenient adjustment of the work surface, poor fixing and clamping effect of welding parts, and inconvenient observation of welding parts, etc. The effect of adjusting, increasing the use function, and lengthening the storage area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

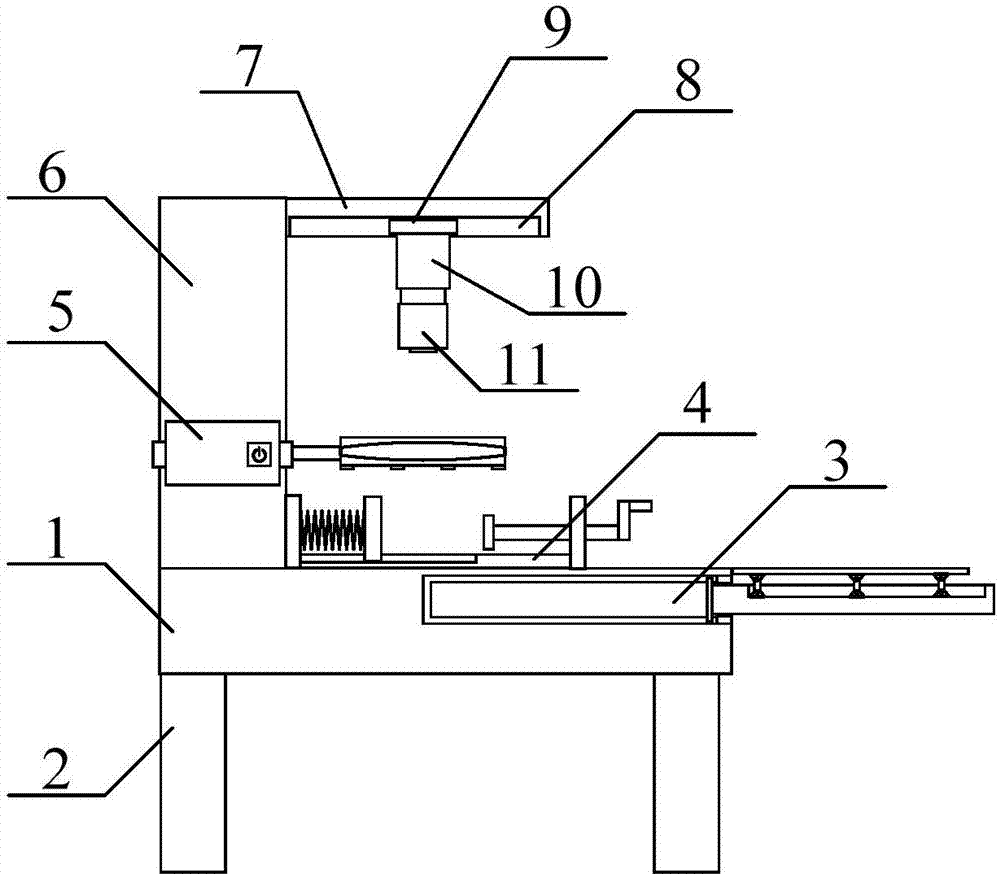

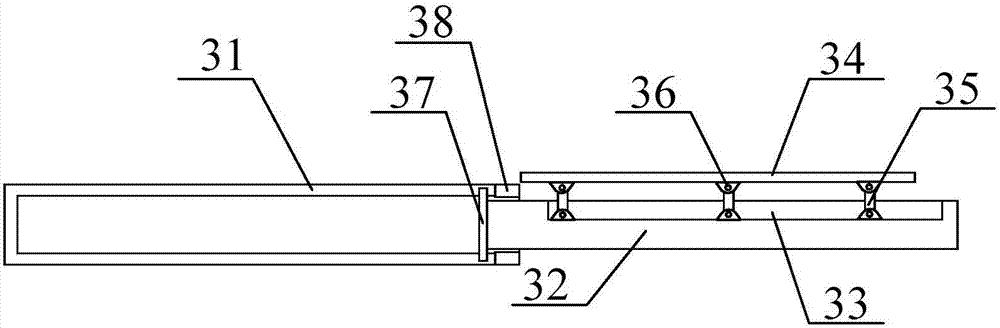

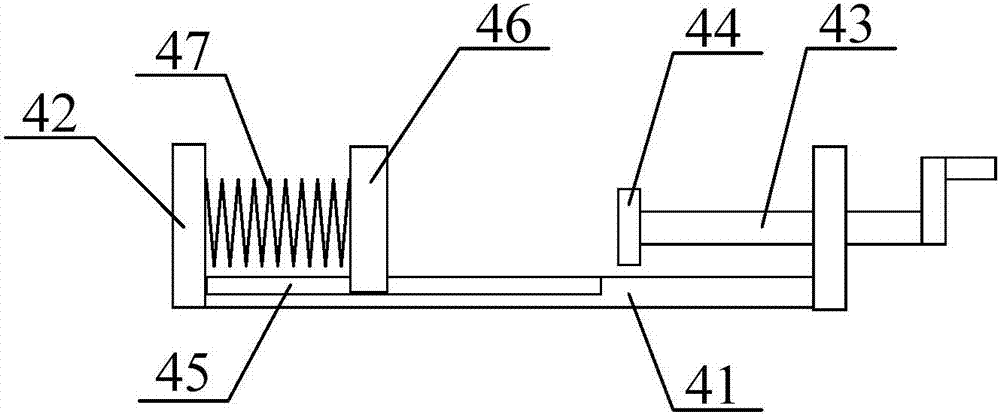

[0027] as attached figure 1 to attach Figure 4 shown

[0028] The invention provides an improved laser welding processing workstation, which includes a workbench 1, supporting legs 2, an elongated plate structure 3, a clamping device for welded parts 4, an enlarged lighting device 5, a support frame 6, a beam 7, and a slide rail 8, The sliding block 9, the cylinder 10 and the laser welding head 11, the support legs 2 are welded on the left and right sides of the lower part of the workbench 1; the elongated plate structure 3 is embedded in the right side of the workbench 1; the welded parts The clamping device 4 is installed on the top of the workbench 1; the support frame 6 is welded on the upper left side of the workbench 1; the bolts of the enlarged lighting device 5 are installed on the right side of the support frame 6; the crossbeam 7 Welded on the upper right side of the support frame 6; the slide rail 8 is installed on the lower part of the beam 7; the cylinder 10 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com