Bamboo rolling machine with pressure adjusting function

The technology of a function and pressure regulating device is applied in the field of bamboo pressing machines with pressure regulating function, which can solve the problems of poor rolling effect of bamboo chips, and achieve the effect of improving the effect and efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation of the invention will be further described below in conjunction with the accompanying drawings.

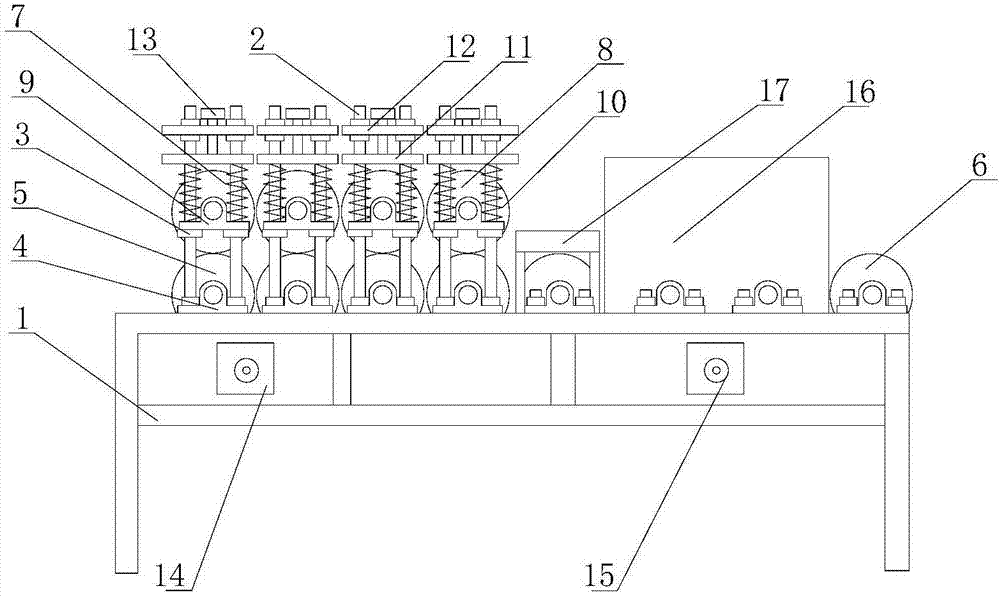

[0026] Such as figure 1 As shown, a bamboo pressing machine with pressure regulating function includes a frame 1, a transmission mechanism, a driving mechanism, a rolling mechanism 7 and a microwave heating box 16.

[0027] Two sets of fixed screw rods are respectively arranged on opposite sides of the frame 1, and the two fixed screw rod groups are arranged symmetrically. The fixed screw group includes a plurality of fixed screw rods 2 arranged at intervals, and the fixed screw rods 2 are all vertically arranged. In this embodiment, each fixed screw group includes sixteen fixed screws 2; among them, eight long fixed screws and eight short fixed screws.

[0028] The conveying mechanism is arranged on the frame 1, which includes several conveying rollers. Both ends of the conveying drum are rotationally connected to the first bearing seat 4, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com