A continuous foaming device for amino sound-absorbing cotton

A foaming device and amino technology are applied in the field of continuous foaming device of amino sound-absorbing foam to achieve the effects of sufficient energy, low energy consumption and appropriate negative pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

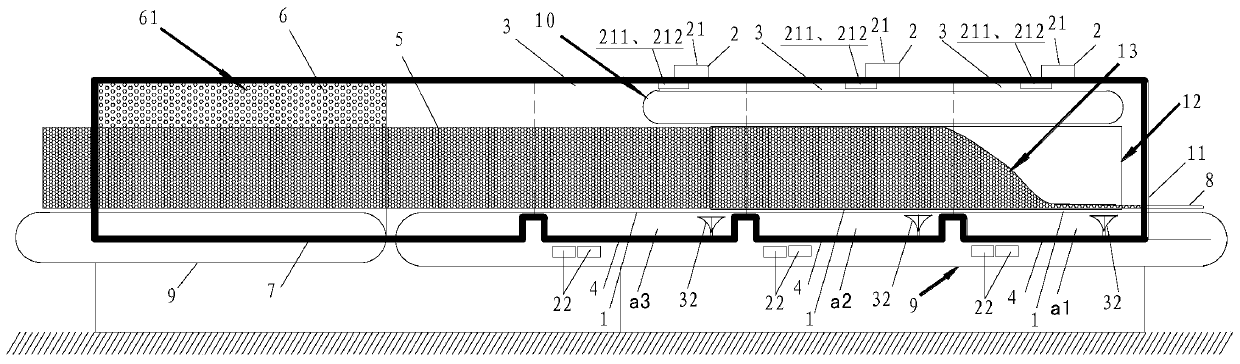

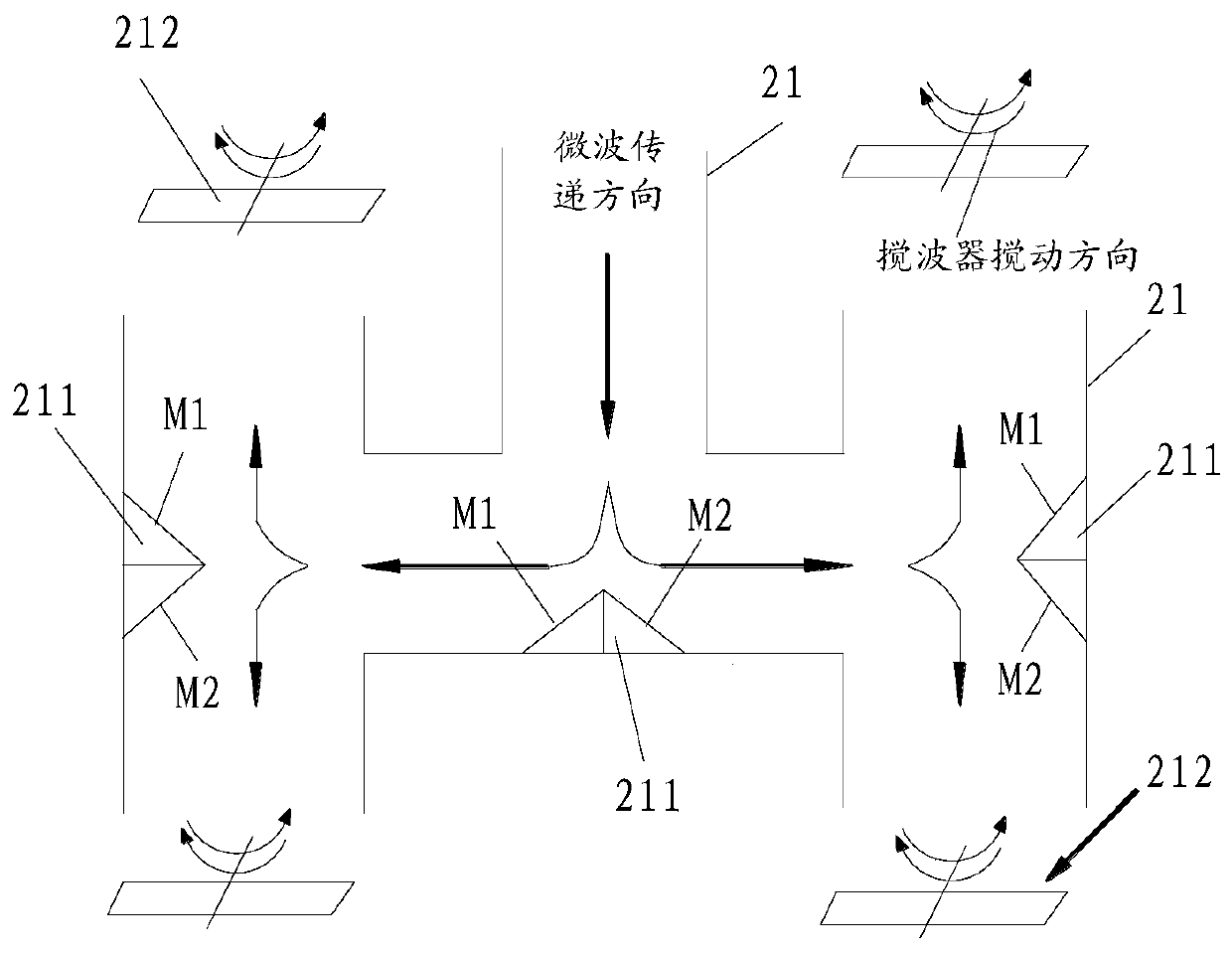

[0030] Embodiment 1: as figure 1 with figure 2As shown, a continuous foaming device for amino sound-absorbing cotton, including a plastic foaming mold 1 with a rectangular foaming channel, a microwave system 2, a foaming air supply and outlet system 3, and a foaming unit of a foaming stainless steel shell 4, The foamed stainless steel shell 4 is set outside the plastic foaming mold 1, and the microwave system 2 is arranged outside the foamed stainless steel shell 4, specifically on the upper part of the foamed stainless steel shell 4 in this embodiment; the foamed air supply The air outlet system 3 is arranged on the outside of the foamed stainless steel shell 4, specifically on the top and left and right sides of the foamed stainless steel shell 4 in this embodiment; the microwave system 2 includes a power supply, a magnetron (ie microwave generator), a microwave The transmission pipe 21 (in this embodiment, the width*height of the microwave transmission pipe 21 is 250mm*13...

Embodiment 2

[0032] Embodiment 2: as figure 1 with image 3 As shown, a continuous foaming device for amino sound-absorbing cotton,

[0033] Compared with embodiment 1, the difference is:

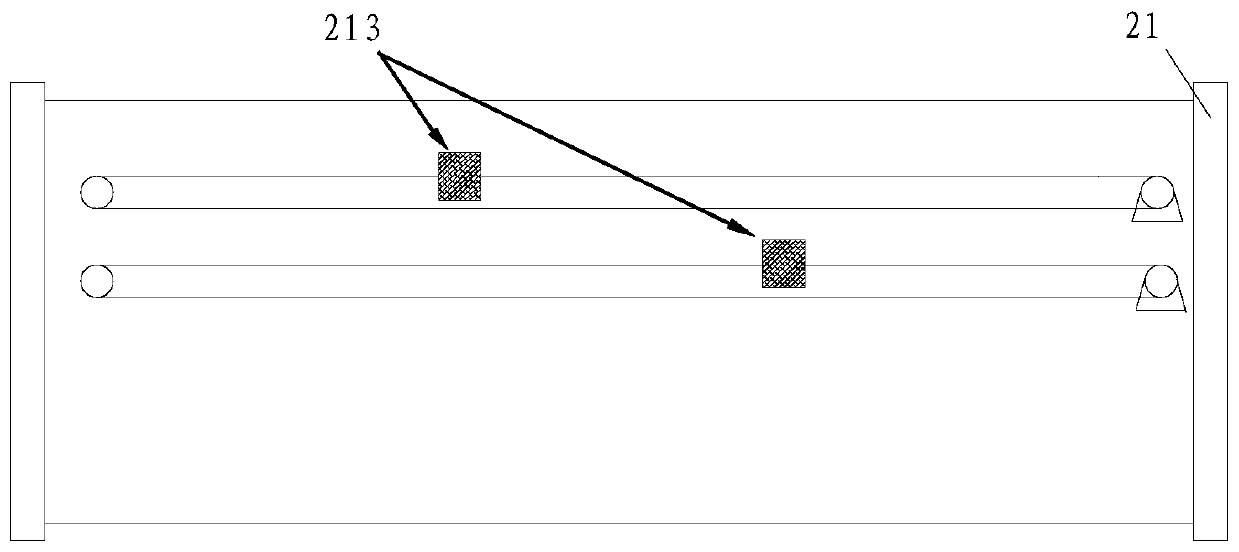

[0034] The microwave system 2 also includes a regulator 213, the cross-section of the microwave transmission pipeline 21 is rectangular, and the regulator 213 is arranged on the outside of the foamed stainless steel casing 4 (in this embodiment, it is the upper part of the foamed stainless steel casing 4). On the outer walls of the left and right sides of the microwave transmission pipe 21 , the regulator 213 is a magnet acting on the left and right sides of the microwave transmission pipe 21 to improve microwave conduction behavior. In this embodiment, the small magnets whose position and spacing can be adjusted constitute the regulator 213. Specifically, the motor connects two small magnets through a synchronous belt, and the position and spacing are adjusted forward and backward along the left and ...

Embodiment 3

[0036] Embodiment 3: as figure 1 with Figure 4 As shown, a continuous foaming device for amino sound-absorbing cotton,

[0037] Compared with embodiment 2, the difference is:

[0038] The microwave system 2 also includes various mode distribution blocks 22, the mode distribution block 22 is a cuboid made of a material with a certain dielectric constant, usually plexiglass or urea-formaldehyde resin, and its dielectric constant is generally 2 to 4. In this embodiment, it is a plexiglass material, the size of which is like a brick (240mm in length, 120mm in width, and 60mm in height). The number and distribution position of the blocks are manually adjusted on the bottom of the foaming mold 1 according to the production form of the sound-absorbing cotton product. The shape of the product is related to the microwave intensity. If a certain position in the plastic foam mold 1 needs to increase the microwave intensity, place it below this position. The denser the placement, the g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com