Layout scheme for pulling system in cat anchor test of wooden mold

An anchor pull test and system layout technology, which is applied in ship components, ships, transportation and packaging, etc., can solve the problem that the anchor cannot obtain smooth and smooth operation and accurate stopping points, increase the factors and variables of the test process, and greatly reduce the finish, etc. problems, to achieve the effect of stable lifting and throwing operation of anchorage, stable and smooth operation process, and effective control of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

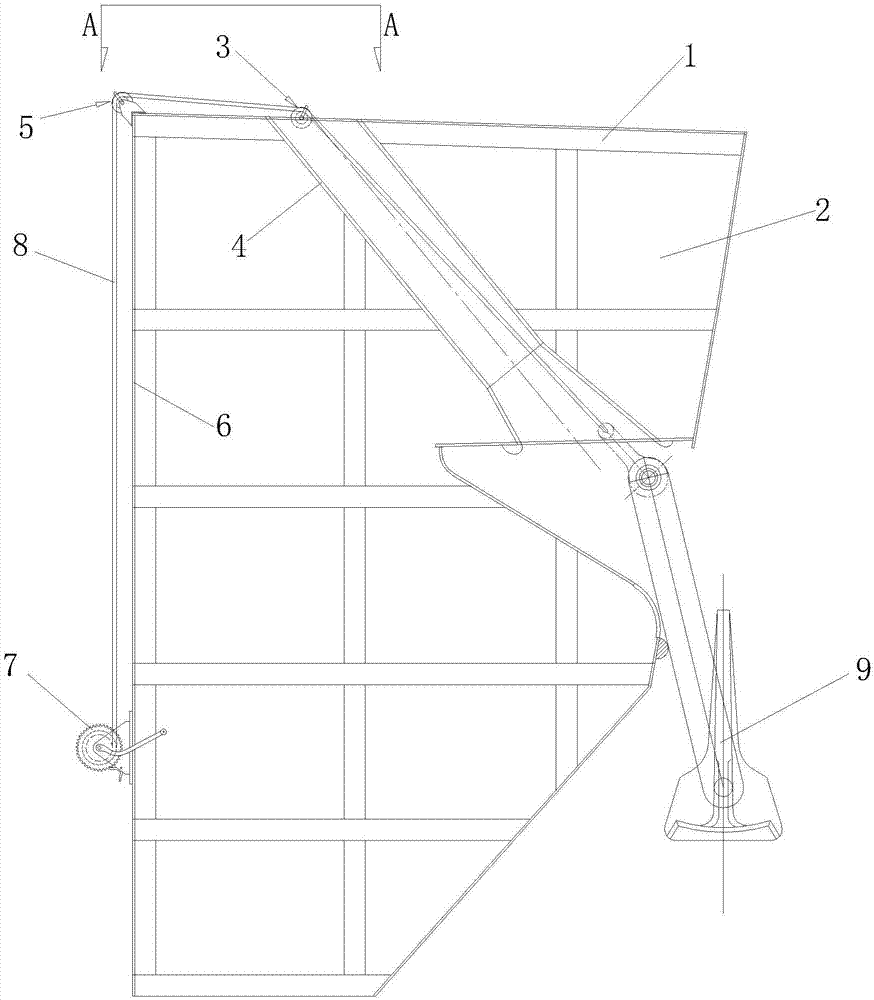

[0021] Such as figure 1 , 2 As shown, this embodiment provides a plan for the layout of the pulling system in the wooden model anchor pulling test, which is arranged on the hull deck 1 and the anchor test box 2, including:

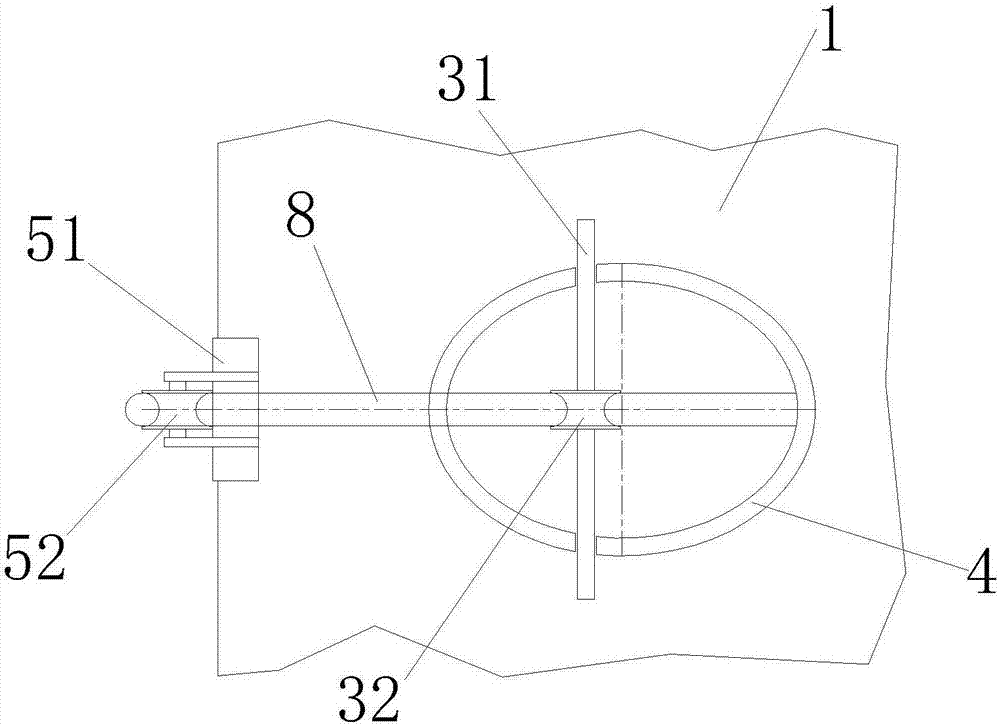

[0022] The fairlead 3 is composed of a shaft rod 31 and a first roller 32 mounted on the shaft rod 31, and is arranged on the top of the chain barrel 4, that is, the central part of the opening between the chain shaft 4 and the deck 1;

[0023] The angle wheel device 5 is composed of a support 51 and a second roller 52 installed on the support 51, arranged on the intersection line of the deck 1 of the anchor test box 2 behind the fairlead 3 and the 6 sides of the box back plate superior;

[0024] The self-locking manual winch 7 is arranged on the box backboard 6 of the anchor test box 2 directly below the corner wheel 5;

[0025] One end of the nylon rope 8 is connected with the anchorage 9, and the other end is connected with the self-locking manual wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com