Bucket elevator carrying out dust removal through circulating air

A bucket elevator, circulating air technology, applied in conveyors, loading/unloading, transportation and packaging, etc., can solve the problems of air pollution, hazards of operation equipment and personnel, sand drift, etc., to achieve efficient circulation and ensure environmental protection and safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

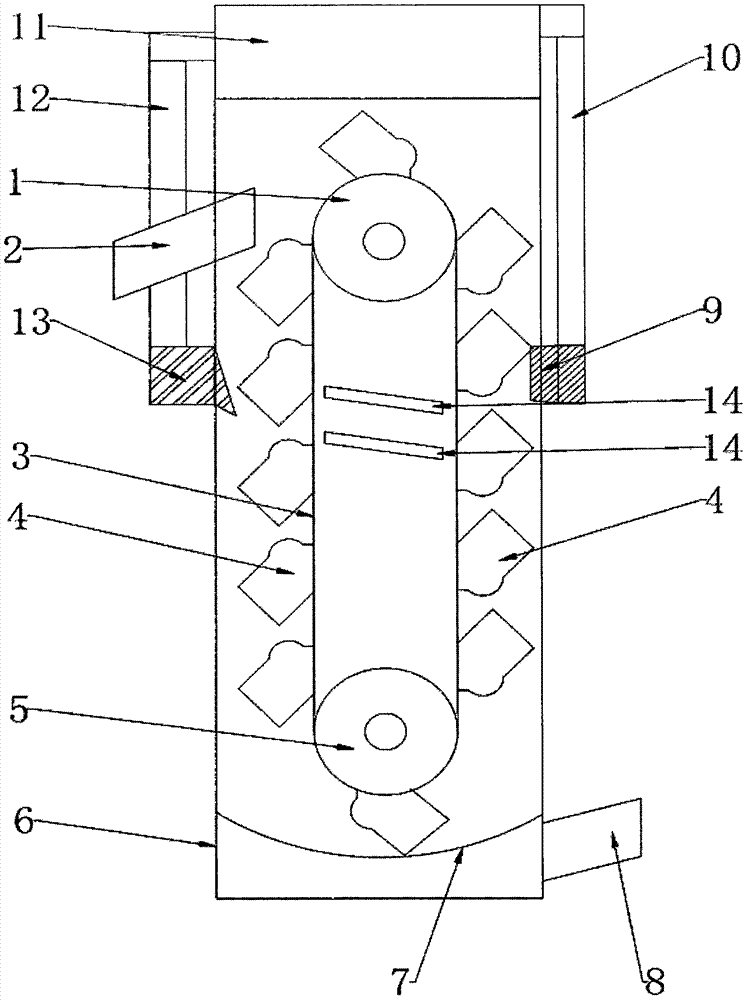

[0015] Such as figure 1 Shown: a bucket elevator for circulating air dust removal, including a chassis 6, the upper and lower parts of the chassis 6 are respectively provided with a driven wheel 1 and a driving wheel 5, the driven wheel 1 and the driving wheel 5 are sleeved with a transmission belt, the transmission belt There are several bucket elevators 4 evenly distributed on the outside of the cabinet 6, the upper left part of the cabinet 6 is provided with a discharge hopper 2, and the lower right part of the cabinet 6 is provided with a feed hopper 8; the left side wall of the cabinet 6 below the discharge hopper 2 is provided with an air outlet 13 , the right side wall of the cabinet 6 is provided with an air hole group 9 at the same height as the air outlet 13, and the air hole group 9 is composed of 5 air holes arranged side by side; the upper end of the cabinet 6 is provided with a dust collector 11, and the dust collector 11 passes through The air suction pipe 12 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com