Air flotation cyclone contactor and air flotation cyclone system

A contactor and air flotation technology, applied in chemical instruments and methods, flotation water/sewage treatment, water/sewage multi-stage treatment, etc., can solve problems affecting the process flow, low efficiency, pollution, etc., and achieve large treatment flow , increase the processing capacity, and improve the separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

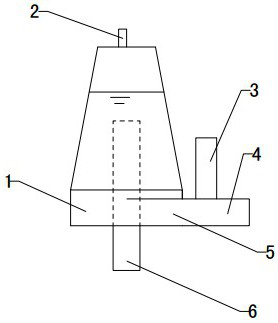

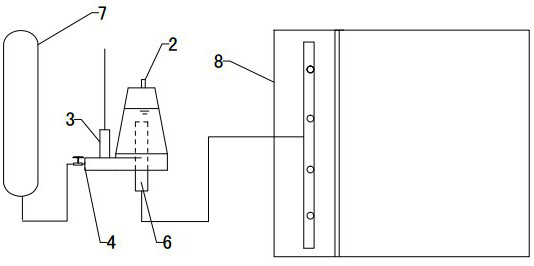

[0025] Reference attached figure 1 : Air-floating cyclone contactor, including a cone 1, the side wall of the cone 1 is connected to a tangentially arranged liquid inlet pipe 5, the top of the cone 1 is provided with an exhaust port 2, and the bottom is provided with a liquid outlet pipe 6. Two branch pipes are provided at the outer end of the liquid inlet pipe 5.

[0026] The cone 1 is a structure with a narrow top and a wide bottom, and the liquid inlet pipe 5 is arranged on the lower side of the cone 1. The top of the cone 1 is provided with an exhaust cavity, and the top of the exhaust cavity is connected with an exhaust port 2. The outlet pipe 6 is arranged concentrically with the cone 1, the upper part of the outlet pipe 6 extends into the inside of the cone 1, and the top of the outlet pipe 6 is arranged on the upper part of the cone 1, and the top of the outlet pipe 6 is higher than the cone 1. The horizontal centerline of the shaped cylinder 1.

[0027] Reference figure ...

Embodiment 2

[0034] The liquid outlet pipe 6 is arranged concentrically with the cone barrel 1, the upper part of the liquid outlet pipe 6 extends into the inside of the cone barrel 1, and the top of the liquid outlet pipe 6 is arranged at the lower part of the cone barrel 1. The top of the liquid outlet pipe 6 is set at the lower part of the cone 1, compared with the top of the liquid outlet pipe 6 arranged on the upper part of the cone 1, it can have a longer residence time while avoiding bubble-suspension polymerization The substance moves to the outer wall of the outlet pipe 6 under the action of centrifugal force, and cannot leave the inner cavity of the cyclone contactor. Other settings and working principles are the same as the first embodiment.

Embodiment 3

[0036] The liquid inlet pipe 5 is arranged on the central side of the cone 1. The liquid inlet pipe 5 is arranged on the side of the middle of the cone 1 to allow the liquid to flow from top to bottom. This method can increase the residence time of the bubbles in the contactor and increase the concentration of the bubbles in the contactor. Other settings and working principles are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com