Liquid flow control device of electronic display glass platinum channel

A platinum channel and electronic display technology, applied in glass manufacturing equipment, glass furnace equipment, manufacturing tools, etc., can solve the problems of difficult control, etc., and achieve the effect of convenient use, simple structure, and low transformation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

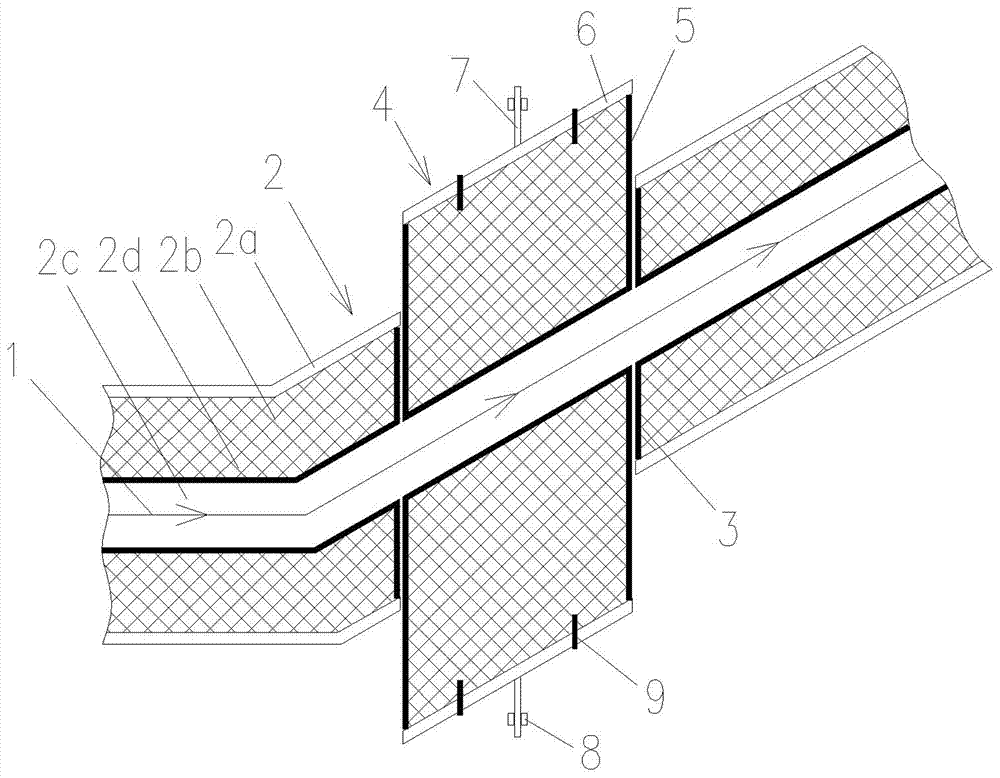

[0014] like figure 1 As shown, a flow control device for electronic display glass platinum channel, it includes: glass liquid outlet 2, the glass liquid outlet 2 includes a steel outer wall 2a, and a refractory The inner lining 2b is provided with a platinum paste layer 2d inside the refractory inner lining 2b, and the inner side of the platinum paste layer is a flow channel 2c corresponding to the molten glass 1 .

[0015] There are notches 3 symmetrically arranged on the glass outlet channel 2, and a corresponding sliding block 4 is provided in each notch 3 to form a movable section. The slider 4 is made of refractory material, and its thickness is greater than that of the glass outlet channel. 2, the thickness of the refractory lining is to ensure that the liquid channel 2 can still be sealed after the movable section is displaced. A gap is provided between the slider 4 and the notch 3, and the width of the gap is less than 3 mm, which can ensure that the glass liquid does...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com