A kind of silver-based antibacterial polyester masterbatch and preparation method thereof

A polyester masterbatch and silver-based technology, applied in the field of functional polymer materials, can solve the problems of difficulty in adapting to the market demand of small batch production and inflexible production methods, and achieve good spinnability, good synergy and low production cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

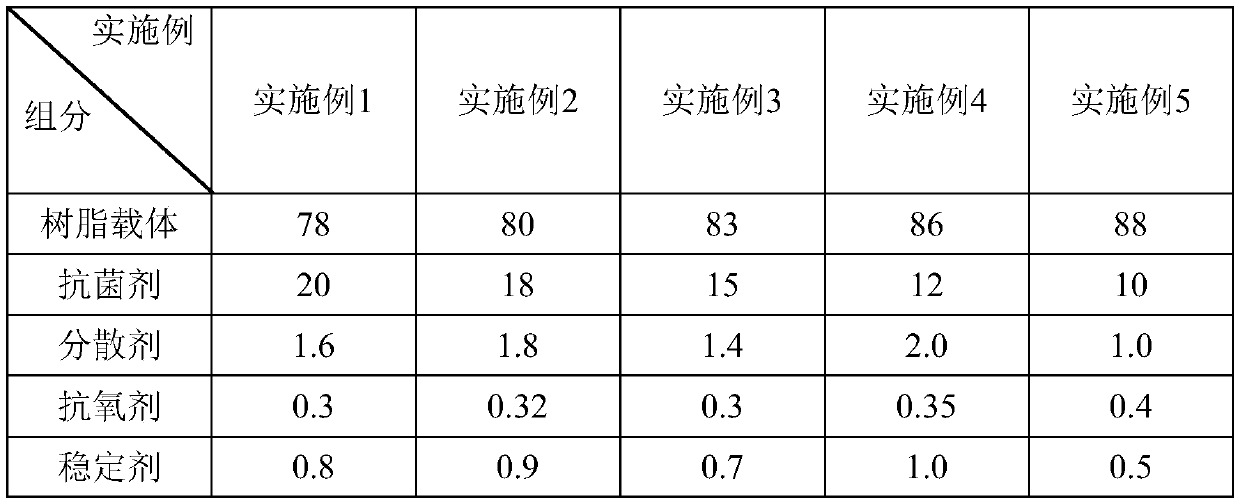

Embodiment 1

[0027] Weigh the components according to Table 1, add them to the drum mixer, mix for 15-20 minutes at room temperature, and then add the evenly mixed materials to the twin-screw extruder to melt and blend. The selected screw is divided into 10 zones, each zone The temperature is 180°C, 200°C, 230°C, 250°C, 250°C, 260°C, 260°C, 260°C, 260°C, 250°C, the screw speed is 100 rpm, and two filter screens are installed in front of the screw extruder. The mesh number of the filter screen is 200, and the meshes of the filter screen are arranged crosswise to improve the filtration accuracy. The silver of the present invention is obtained by shearing and mixing with a twin-screw extruder, then extruding, cooling, pelletizing, and packaging. It is an antibacterial polyester masterbatch.

[0028] The obtained silver-based antibacterial polyester masterbatch has an appearance of white cylindrical particles with uniform size, a particle size of about 3mm*3mm, a melting point of 228°C, heat resi...

Embodiment 2

[0033] Weigh the components according to Table 1, add them to the drum mixer, mix for 15-20 minutes at room temperature, and then add the evenly mixed materials to the twin-screw extruder for melt blending. The selected screw is divided into 11 zones, each zone The temperature is 180°C, 200°C, 230°C, 250°C, 250°C, 260°C, 260°C, 260°C, 260°C, 250°C, 250°C, the screw speed is 150 revolutions per minute, and two pieces are installed before the screw extrusion port Filter, the mesh number of the filter is 230, and the mesh of the filter is arranged in a cross pattern to improve the filtration accuracy. It is cut and mixed by a twin-screw extruder, then extruded, cooled, pelletized, and packaged. Invented silver antibacterial polyester masterbatch.

[0034] The resulting silver-based antibacterial polyester masterbatch is white in appearance, with a particle size of about 3mm*3mm, a melting point of 228.5°C, heat resistance, an intrinsic viscosity of 0.73dl / g, and a filtration pressur...

Embodiment 3

[0037] Weigh the components according to Table 1, add them to the drum mixer, mix for 15-20 minutes at room temperature, and then add the evenly mixed materials to the twin-screw extruder to melt and blend. The selected screw is divided into 10 zones, each zone The temperature is 180°C, 200°C, 230°C, 250°C, 250°C, 260°C, 260°C, 260°C, 260°C, 250°C, the screw speed is 200 rpm, and two filters are installed in front of the screw extrusion port. The mesh number of the filter screen is 250, and the meshes of the filter screen are arranged crosswise to improve the filtration accuracy. The silver of the present invention is obtained by shearing and mixing with a twin-screw extruder, then extruding, cooling, pelletizing, and packaging. It is an antibacterial polyester masterbatch.

[0038] The resulting silver-based antibacterial polyester masterbatch is white in appearance, with a particle size of about 3mm*3mm, a melting point of 228.6°C, heat resistance, an intrinsic viscosity of 0.7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com