Well-used large-displacement ultrahigh-pressure supercritical carbon dioxide booster pump and conveying method

A technology of carbon dioxide and ultra-high pressure, applied in the direction of pumps, piston pumps, pump components, etc., can solve problems such as unorganized leakage, unsatisfactory, dangerous, etc., achieve convenient pressure and speed adjustment, realize transportation and storage, and improve use The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

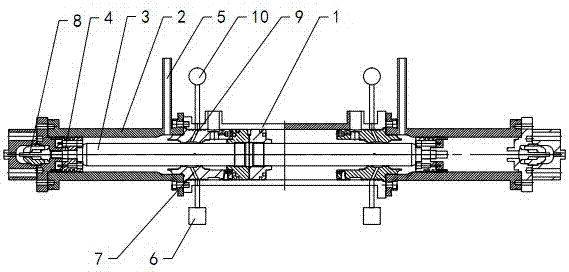

[0026] figure 1 It is the best embodiment of the large-displacement ultra-high pressure supercritical carbon dioxide booster pump and device for this well. The following is combined with the attached figure 1 The present invention will be further described.

[0027] see figure 1 , the large-displacement ultra-high pressure supercritical carbon dioxide booster pump for this well includes a hydraulic cylinder 1, a pump body 2 and a piston 3, the piston 3 is slidably arranged in the pump body 2 and connected to the output end of the hydraulic cylinder 1, and the hydraulic cylinder 1 Horizontally arranged, one end of the piston 3 is provided with a liquid inlet valve 4, the other end is connected to the output end of the hydraulic cylinder 1, one end of the pump body 2 is connected to a liquid discharge valve 8, and the other end is provided with a supercritical carbon dioxide input pipe 5, and the supercritical carbon dioxide input The tube 5 is provided on the side of the pump...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com