Inverse-proportion three-way flow valve

A three-way flow valve, inverse proportional technology, used in multi-way valves, valve details, safety valves and other directions, can solve the problems of easy failure, high machining accuracy, high assembly requirements, large volume, etc., to achieve compact structure, reasonable structure, Small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

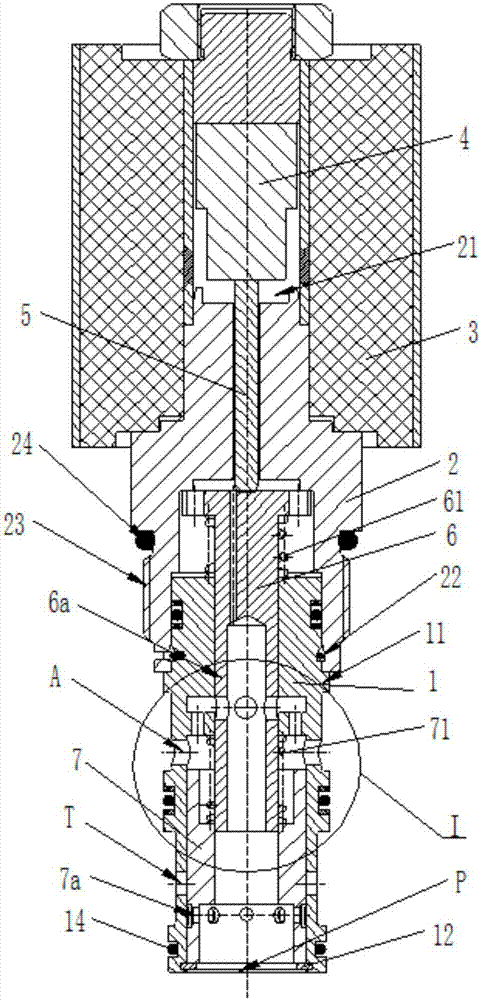

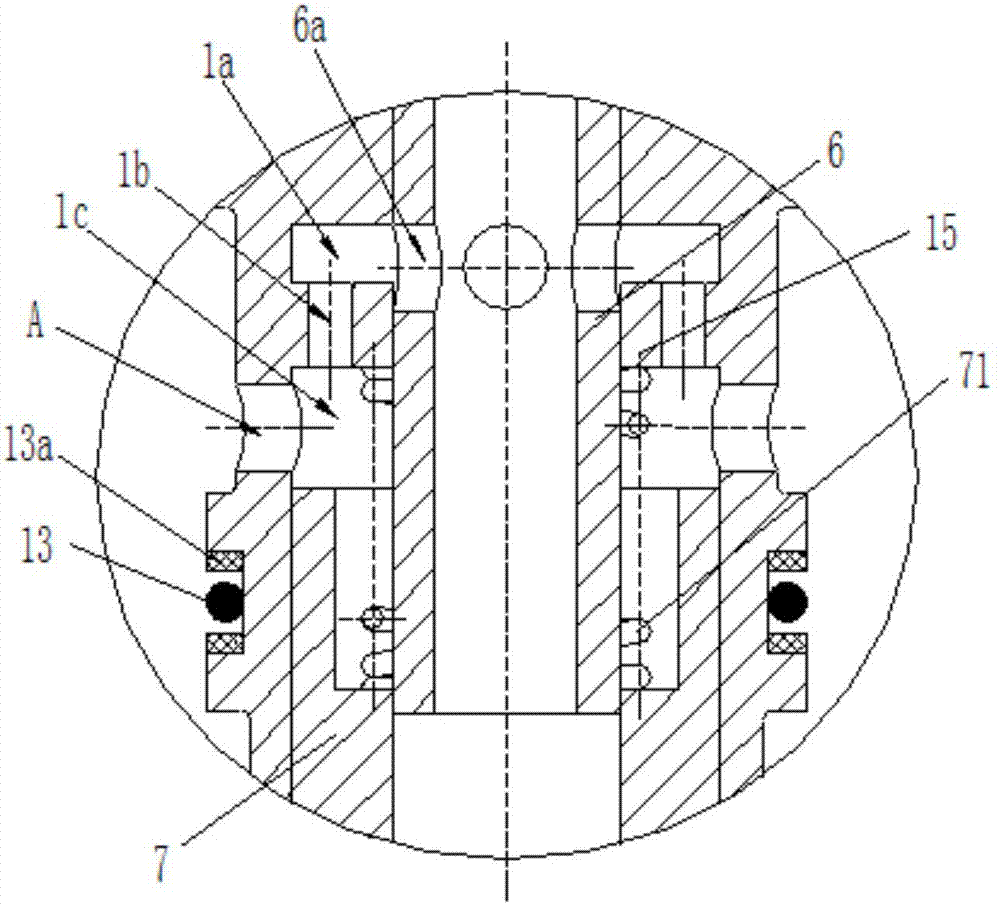

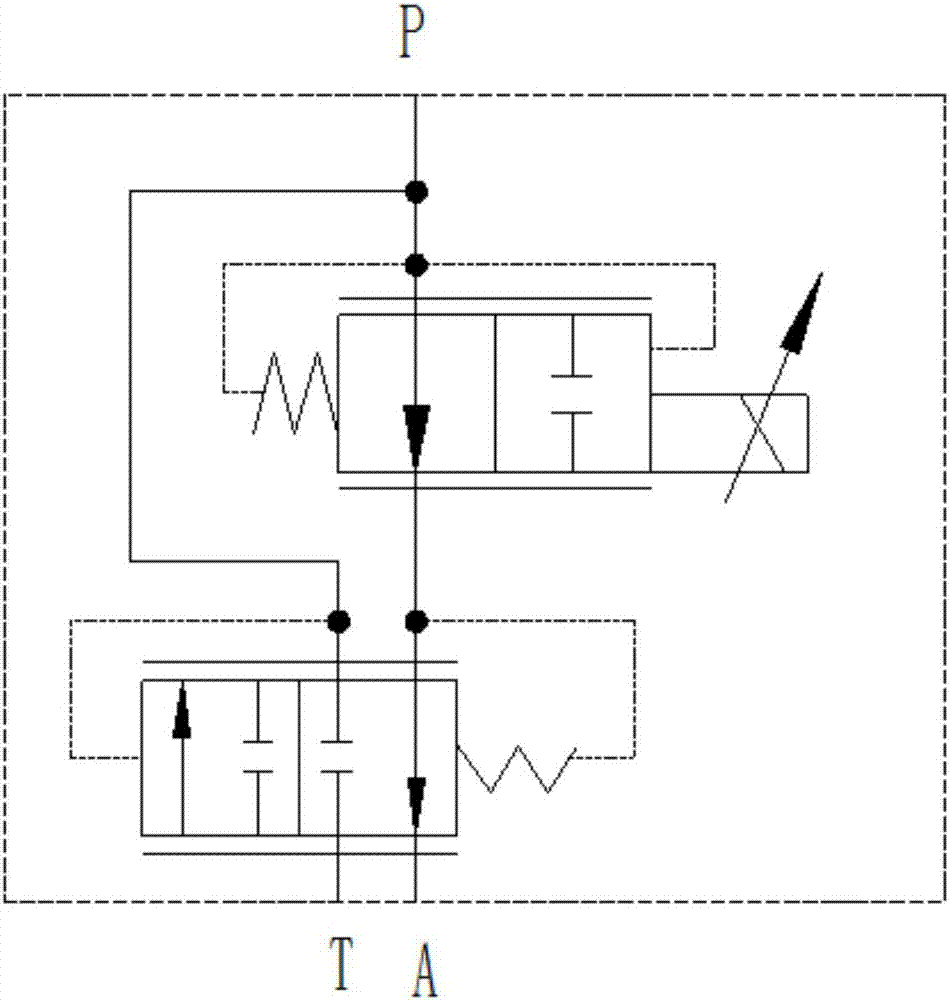

[0027] Such as Figure 1 to Figure 3 Shown is the structural representation of the present invention,

[0028] The reference signs are: P port, T port, A port, valve body 1, flow chamber 1a, flow hole 1b, differential pressure feedback chamber 1c, boss 11, retaining ring 12, first valve body sealing ring 13. Retaining ring 13a, second valve body sealing ring 14, sealing shoulder 15, valve sleeve 2, groove 21, circlip 22, external thread 23, valve sleeve sealing ring 24, proportional electromagnet 3, armature 4, top Rod 5, throttle spool 6, throttle control hole 6a, throttle spring 61, differential pressure compensation spool 7, compensation channel hole 7a, compensation spring 71.

[0029] Such as Figure 1 to Figure 3 as shown,

[0030] The inverse proportional three-way flow valve includes a valve body 1, which is provided with P port, T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com