Creep test device for concrete filled steel tubes considering the initial stress of steel tubes

A technology of concrete-filled steel pipe and initial stress, which is applied in the direction of applying stable tension/pressure to test the strength of materials, and can solve problems such as stress application of steel pipe concrete structures, difficulty in controlling the balance of test devices, and increased manpower and material resources, making it difficult to manufacture and process Small size, high promotion and application value, and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

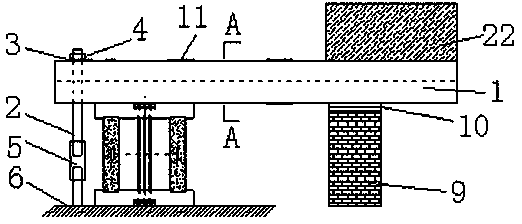

[0024] The conception, specific details and obtained technical effects of the present invention will be further described below in conjunction with the accompanying drawings. The lever loading method is loaded by directly placing a counterweight on the upper part of the lever beam, which is convenient for applying large-sized counterweights, and can effectively ensure the lateral stability of the loading device and the constant applied external load. The loading device is simple, and can meet the load of the creep test of the concrete filled steel pipe under the initial stress state.

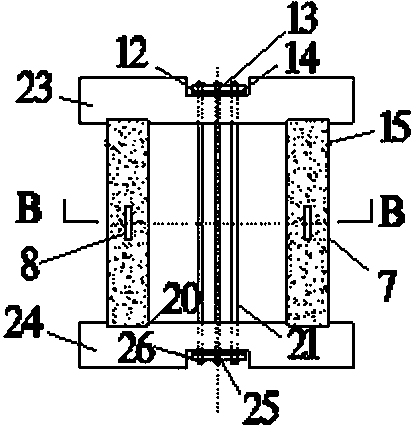

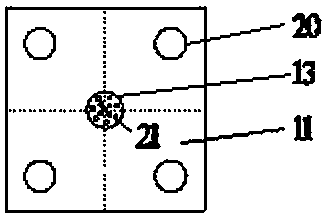

[0025] figure 1 and figure 2 A test device for applying initial stress to a steel pipe according to an embodiment of the present invention is schematically given. figure 1 The initial stress loading device of the steel pipe includes the upper steel plate 23, the lower steel plate 24, the concrete in the pipe 19, the threaded steel bar 21, the steel pipe concrete test block 7, the vibrating wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com