Optimized design method for rectangular cross-section radiator fin

A rectangular cross-section, optimized design technology, applied in computer-aided design, design optimization/simulation, instruments, etc., can solve the problem of non-optimal heat dissipation of rectangular heat sinks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to illustrate the technical scheme and technical purpose of the present invention, the present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

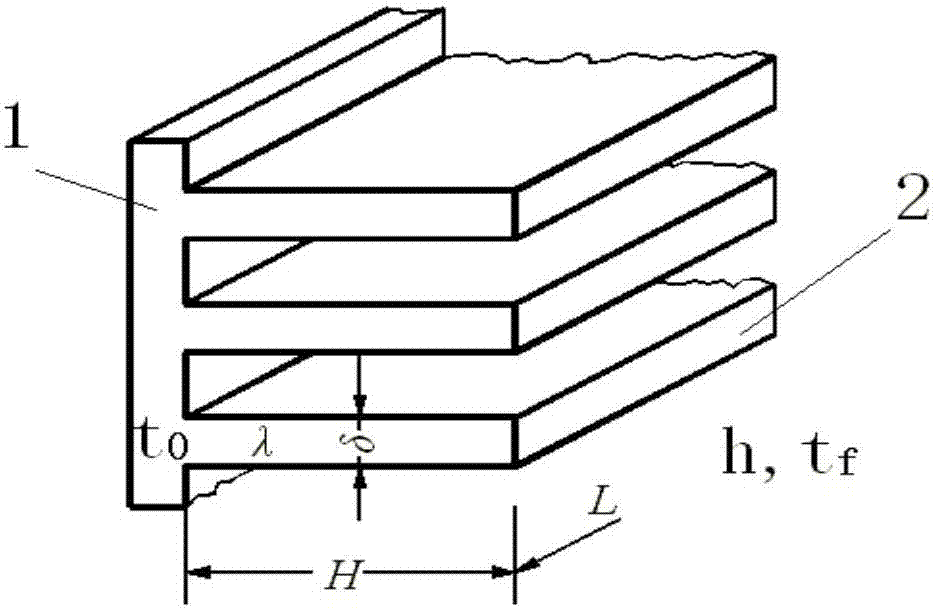

[0018] figure 1 It is a structural schematic diagram of a rectangular cross-section fin and a radiator main body, wherein the rectangular cross-section fin 2 is vertically arranged on the surface of the radiator main body 1 .

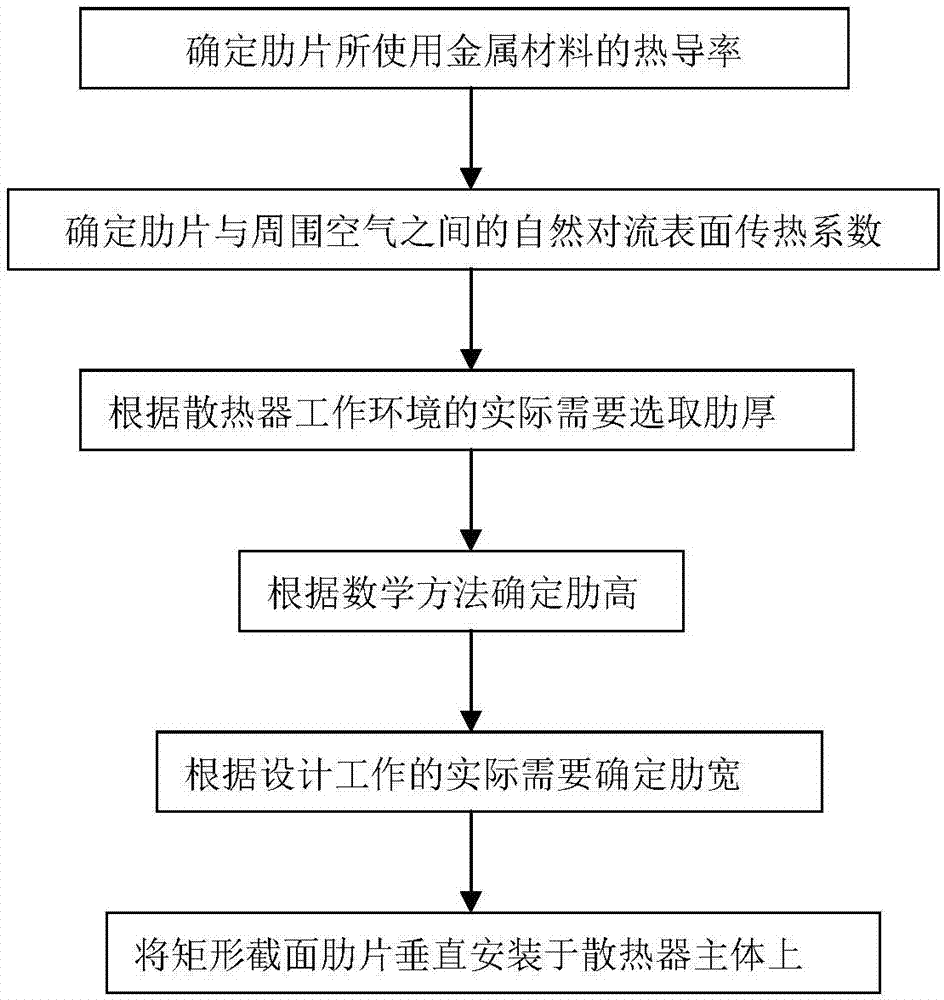

[0019] combine figure 2 , the optimal design method of a kind of rectangular section radiator fin of the present invention, comprises the following steps:

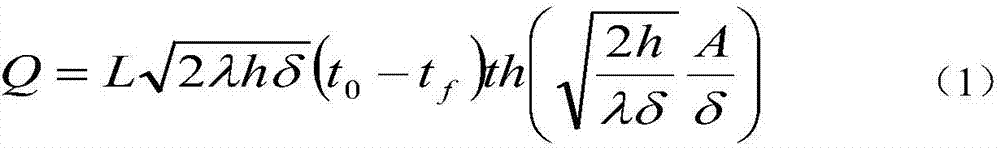

[0020] Step 1. According to the selected metal material of the radiator fin and the working temperature of the fin, check the thermal conductivity λ[(W / (m·K)] of this metal material from the material thermal physical property table.

[0021] Step 2. Use the general test method in heat transfer, or calculate according to the empirical formula, to obtain the natural convecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com