Aircraft regular inspection plan making method and device

A technology for plan preparation and aircraft regular inspection, applied in the field of data processing, can solve problems such as unfavorable parking time maintenance base maintenance decision-making, high labor cost, easy to ignore, etc., to overcome the unreliable information of the regular inspection plan and solve the labor cost problem Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

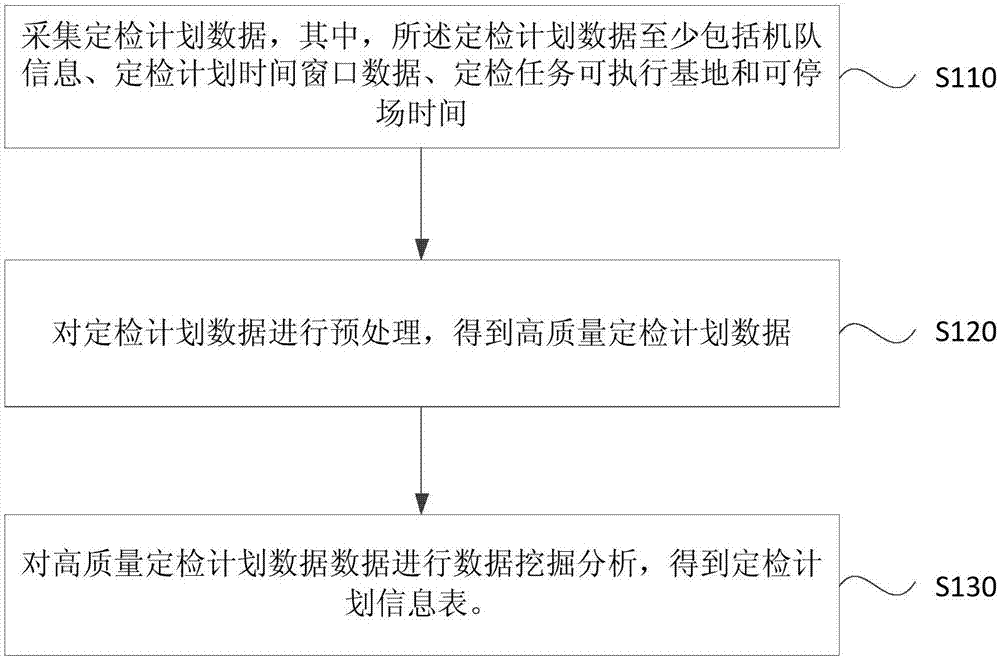

[0022] figure 1 A flow chart of a method for preparing a regular inspection plan provided by an embodiment of the present invention, specifically including the following steps:

[0023] S110. Collect data of the regular inspection plan, wherein the data of the regular inspection plan at least includes fleet information, time window data of the regular inspection plan, executable bases of the regular inspection task, and available parking time.

[0024] Regular inspection is the regular maintenance work carried out by airlines on aircraft. After a period of flight, aircraft engines and on-board equipment will become loose and corroded due to wear and tear. The quality of hydraulic oil and lubricating oil in aircraft systems will deteriorate. Deterioration and the number will decrease, and it needs to be replaced or replenished. Therefore, after the aircraft has been flying for a period of time, the maintenance personnel must carry out relevant inspections and repairs, find and ...

Embodiment 2

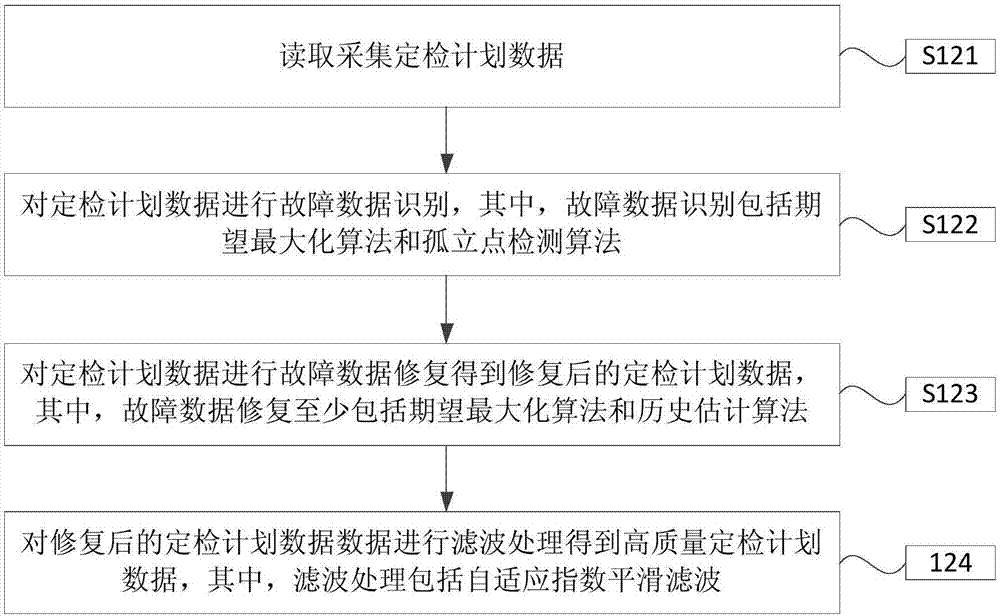

[0033] The embodiment of the present invention also provides a flow chart of preprocessing the data of the regular inspection plan, as a further description of the first embodiment, as shown in figure 2 As shown, step S120 includes:

[0034] S121. Read and collect the scheduled inspection plan data;

[0035] S122. Perform fault data identification on the regular inspection plan data, wherein the fault data identification includes an expectation maximization algorithm and an outlier detection algorithm;

[0036] After collecting the scheduled inspection plan data, carry out fault data identification. Fault data identification is to identify the information in the data that is obviously inconsistent with the actual situation through various logic algorithms. This logic algorithm can be an expectation maximization algorithm or an outlier detection algorithm.

[0037] S123. Repairing the fault data of the regular inspection plan data to obtain repaired regular inspection plan d...

Embodiment 3

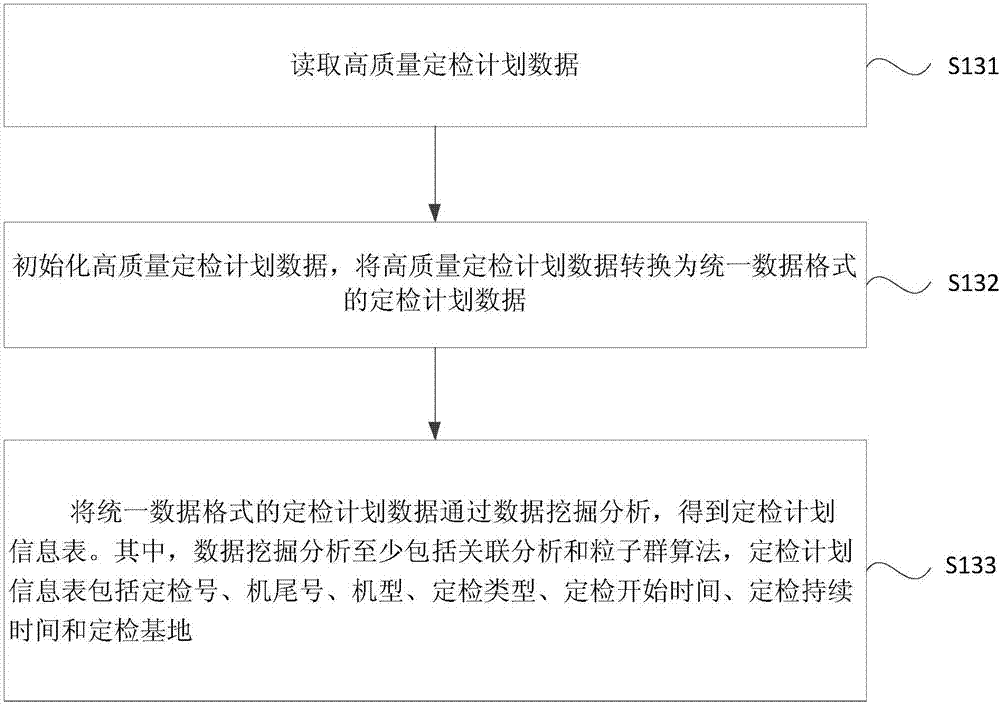

[0042] The embodiment of the present invention also provides a flow chart of data mining and analysis of regular inspection plan data, as a further description of the above embodiment, as shown in image 3 As shown, step S130 includes:

[0043] S131. Read high-quality regular inspection plan data.

[0044] S132. Initialize high-quality regular inspection plan data, and convert the high-quality regular inspection plan data into regular inspection plan data in a unified data format.

[0045] The purpose of initialization is to convert different types of data in the data into a unified data format. The regular inspection plan data includes different themes and different data types. Through initialization processing, all data are converted into a unified data format to facilitate data mining. analyze.

[0046] S133. Analyze the regular inspection plan data in a unified data format through data mining to obtain a regular inspection plan information table. Among them, the data mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com