Novel anti-scaling electric heating pipe and water heater

A technology for electric heating tubes and water heaters, applied in fluid heaters, ohmic resistance heating, ohmic resistance heating components, etc., can solve the problems of electric heating tube heat transfer differences, inapplicability, and large limitations, and achieve increased contact The effect of saving area, saving electric energy and improving heating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

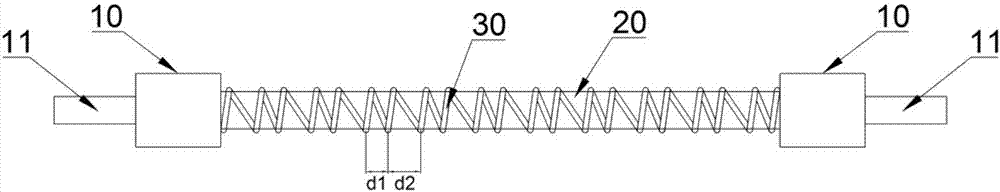

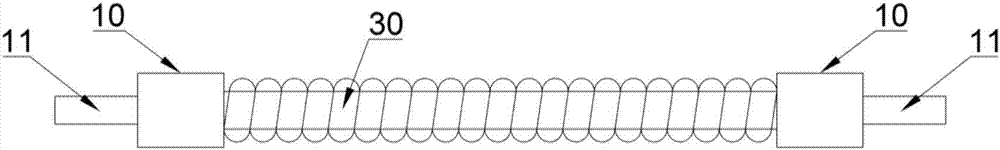

[0062] Such as figure 1 , figure 2 As shown, a new scale-inhibiting electric heating tube described in this embodiment includes a mounting base 10, an electric heating tube 20, a temperature-sensitive expansion wire 30, and a conductive sheet 11, wherein the electric heating tube 20 is a linear electric heating tube , and both ends are fixed, and the temperature-sensitive expansion wire 30 is tightly wound on the outer wall of the electric heating tube 20. The thread space includes two kinds of spaces. The gap between d2 and d2 is set at intervals, the two ends of the temperature-sensitive expansion wire 30 are respectively fixed on the mounting seats 10 on both sides, the two ends of the electric heating tube 20 are respectively fixed on the mounting seats 10 on both sides, and the mounting seats 10 on both sides are respectively fixed. Conductive sheets 11 are provided on the top, and the conductive sheets 11 are connected to the electric heating tube 20. The outer wall of...

Embodiment 2

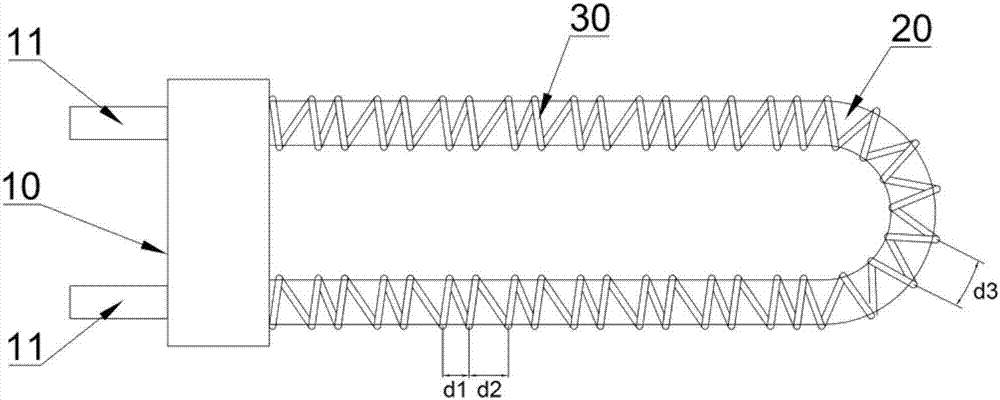

[0066] Such as image 3 As shown, a new anti-scaling electric heating tube described in this embodiment includes two mounting bases 10, a U-shaped electric heating tube 20, a temperature-sensitive expansion wire 30, two conductive sheets 11, and two conductive sheets 11 They are respectively installed on two mounting bases 10, and are respectively electrically connected to the two ends of the electric heating tube 20. The temperature-sensitive expansion wire 20 is tightly wound on the outer wall of the electric heating tube 20, and the thread formed by the temperature-sensitive expansion wire 20 There is a gap between them, and the space distance is d1a2>a3, thermal expansion The induction temperature of silk is 50°~450°C.

[0067] After electrification, the temperature-sensitive expansion wire 20 will be heated and expanded, and the temperature-sensitive expansion wires d1, d2, and d3 respectively correspond to the stretching amounts △L1, △L2, and △L3, which will make △L1>△L...

Embodiment 3

[0071] Such as Figure 5 As shown, a new scale-inhibiting water heater described in this embodiment includes a tank body 40, a special-shaped electric heating tube 20 located in the tank body 40, a mounting seat 10 for installing the electric heating tube 20, and a temperature-sensitive expansion wire 30. The two ends of the temperature-sensitive expansion wire 30 are respectively fixed on the two mounting bases 10, the temperature-sensitive expansion wire 20 is spirally wound on the outer wall of the electric heating tube 30, and there is a gap between the threads formed by the temperature-sensitive expansion wire 20 , and includes gaps of various pitches, wherein, gap pitches of multiple intervals can be set, for example, d1≠d2≠d3≠d4≠d5≠d6≠d7, or d1≠d2, d2≠d3≠d4, attached Figure 5 The distance dn of the middle gap only distinguishes different combinations, and it should be understood by those skilled in the art that it is only necessary to leave a gap between the threads fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com