Iron ore comprehensive beneficiation unit and application method thereof

An iron ore and unit technology, applied in the field of iron ore comprehensive beneficiation unit, can solve the problems of manual operation, waste rock and waste water can not be rationally used, and achieve the effect of improving accuracy and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

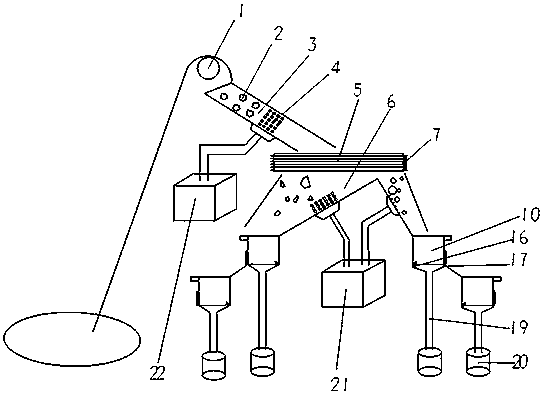

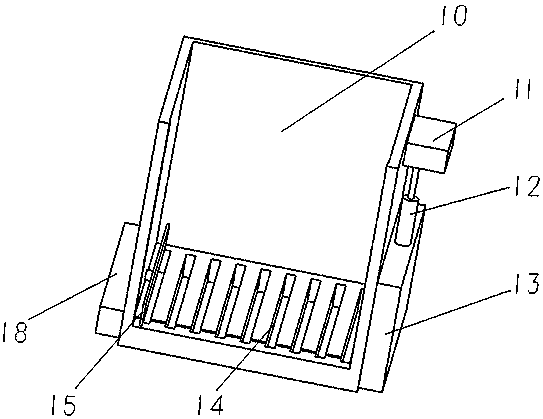

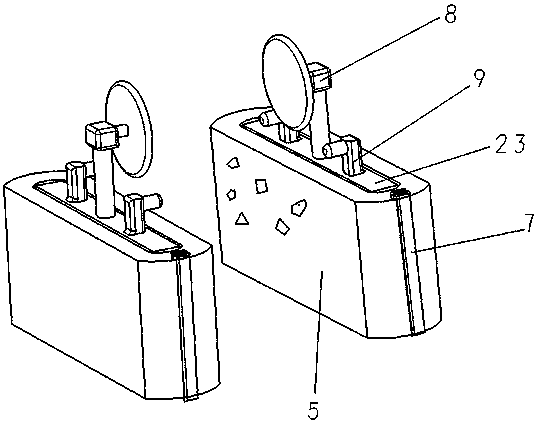

[0026] like figure 1As shown, a comprehensive iron ore beneficiation unit includes a material suction device 1, a separation device 3, a transport device 5, a screening device, a water circulation device and a cleaning device 9; the water circulation device includes a water circulation device one 22 and a water circulation device two 21 The bottom of the suction device 1 is provided with a separation device 3 and does not contact each other. The discharge port of the suction device 1 is located on the top of the separation device 3 but does not contact each other; the bottom of the separation device 3 is provided with a water circulation device. 22. The tail groove part of the separation device 3 is provided with a hole 4, and a waste water receiving port is provided under the hole 4, and the waste water receiving port introduces waste water into the water circulation device through a pipeline; the outlet on the separation device 3 The material can fall or be absorbed from the...

Embodiment 2

[0029] The structure and principle of this second embodiment are basically the same as that of the first embodiment. The difference is that the connecting pipe 19 is replaced by a transmission trough, which can not only send the iron ore to the storage box 20 for classification, but also change the transmission method from closed to is open.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com