Simple multi-station rapid die changing device

A multi-station, fast technology, applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of unsatisfactory automatic production, impact of mold change speed, time-consuming and laborious disassembly of mold replacement, etc., to achieve independent rapid dismantling and The effect of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing

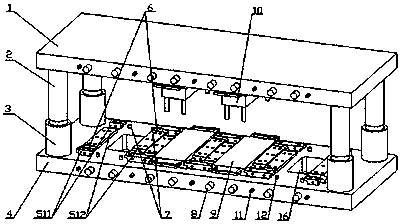

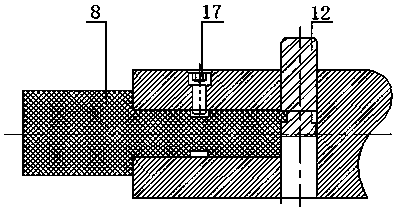

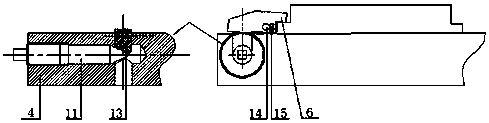

[0012] Such as figure 1 , figure 2 and image 3 As shown, a simple multi-station rapid mold change device includes an upper mold base 1, a guide post 2, a guide sleeve 3, a lower mold base 4, a short guide rail 511, a long guide rail 512, a clamping plate 6, and a coarse positioning screw 7. Knob 8, lower mold 9, upper mold 10, clamping screw 11, positioning pin 12, ejector pin 13, shaft 14, support spring 15, lower mold hole 16, stop screw 17; , the lower mold 9 slides along the guide rails 511 and 512 in a "drawer-like" manner, and the positioning pin 12 is controlled by the rotation of the control knob 8, and the positioning pin 12 reciprocates linearly up and down along the round hole on the mold base with the rotation of the knob 8 movement, reaching the highest point at clock direction 12, and completing the positioning of the lower mold 9; when the pressing plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com