Milling clamping tool for an irregular outward convex side face of round thin sheet with center hole

A clamping tooling and irregular technology, applied in the direction of clamping device, clamping, positioning device, etc., can solve the problems of inability to adapt, and achieve the effect of convenient clamping, material saving and rapid processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

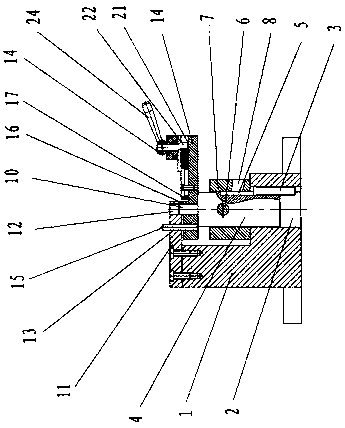

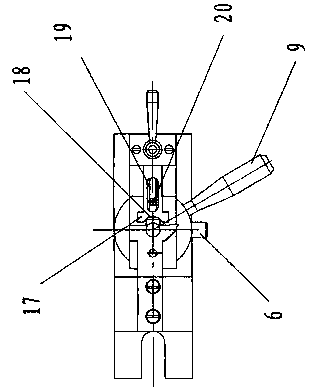

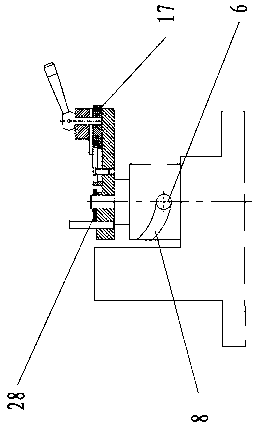

[0015] The present invention is described in detail below in conjunction with accompanying drawing:

[0016] A milling and clamping tool for the irregular convex side of a circular sheet with a central hole, including a stepped base block 1, a central through hole 2 in the up and down direction is arranged on the lower step of the stepped base block 1, and the central through hole 2 in the up and down direction The inner wall is provided with up and down direction guide keys 3, and a cylinder 4 is movably arranged in the central through hole 2 in the up and down direction, and a guide key groove 5 is arranged on the outer wall of the cylinder 4, and the up and down direction guide keys 3 are arranged in the guide key groove 5 , a cylindrical sleeve 7 is movably arranged on the platform of the lower step, an upwardly inclined spiral groove 8 is provided on the side wall of the cylindrical sleeve 7, and the cylinder 4 is movably arranged in the cylindrical sleeve 7, and the The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com