Front overhang swing arm stabilizer rod device for cab of heavy duty vehicles

A technology for heavy-duty trucks and cabs, which is applied to cantilevers, suspensions, vehicle parts, etc. mounted on pivots, which can solve the problems of poor wear resistance, prone to abnormal noise, and easy aging of rubber, so as to reduce processing costs. , Improve reliability and safety, the effect of stable structural performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

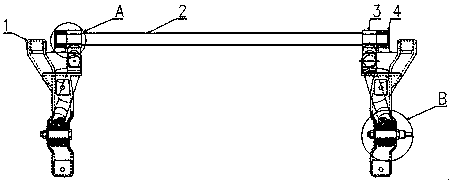

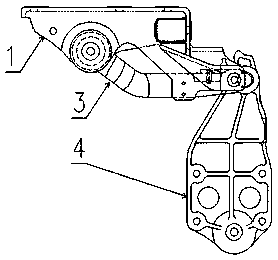

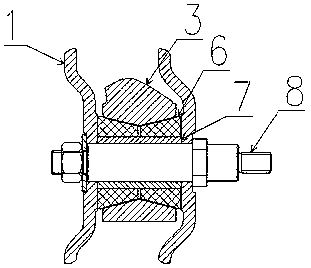

[0030] Such as Figure 1-4 As shown, this embodiment is a front suspension arm stabilizer bar device for a heavy-duty truck cab, including a front suspension upper bracket 1, which is installed at the bottom of the cab, and the front suspension upper bracket 1 is hinged with a front suspension Arm 3, the front end of the front suspension arm 3 is fixedly connected with the stabilizer bar 2, the front suspension arm 3 and the stabilizer bar 2 are hinged with the front suspension support 4, the front suspension support 4 is assembled on the vehicle frame, the front suspension arm 3 The ends are provided with tapered holes on opposite sides of the hinge of the front suspension upper bracket 1, and the tapered holes on both sides are provided with polyurethane bearings 6 whose outer sides are conical. The inner holes of the pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com