Heavy oil reservoir cold recovery method adopting carbon dioxide energy storage and high pressure viscosity reduction

A technology for carbon dioxide and heavy oil reservoirs, which is applied in the fields of production fluid, earthwork drilling and production, sustainable manufacturing/processing, etc., can solve the problems of low recovery degree, achieve enhanced flow and fluidity, improve driving energy, and improve overall The effect of recovery degree and development effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

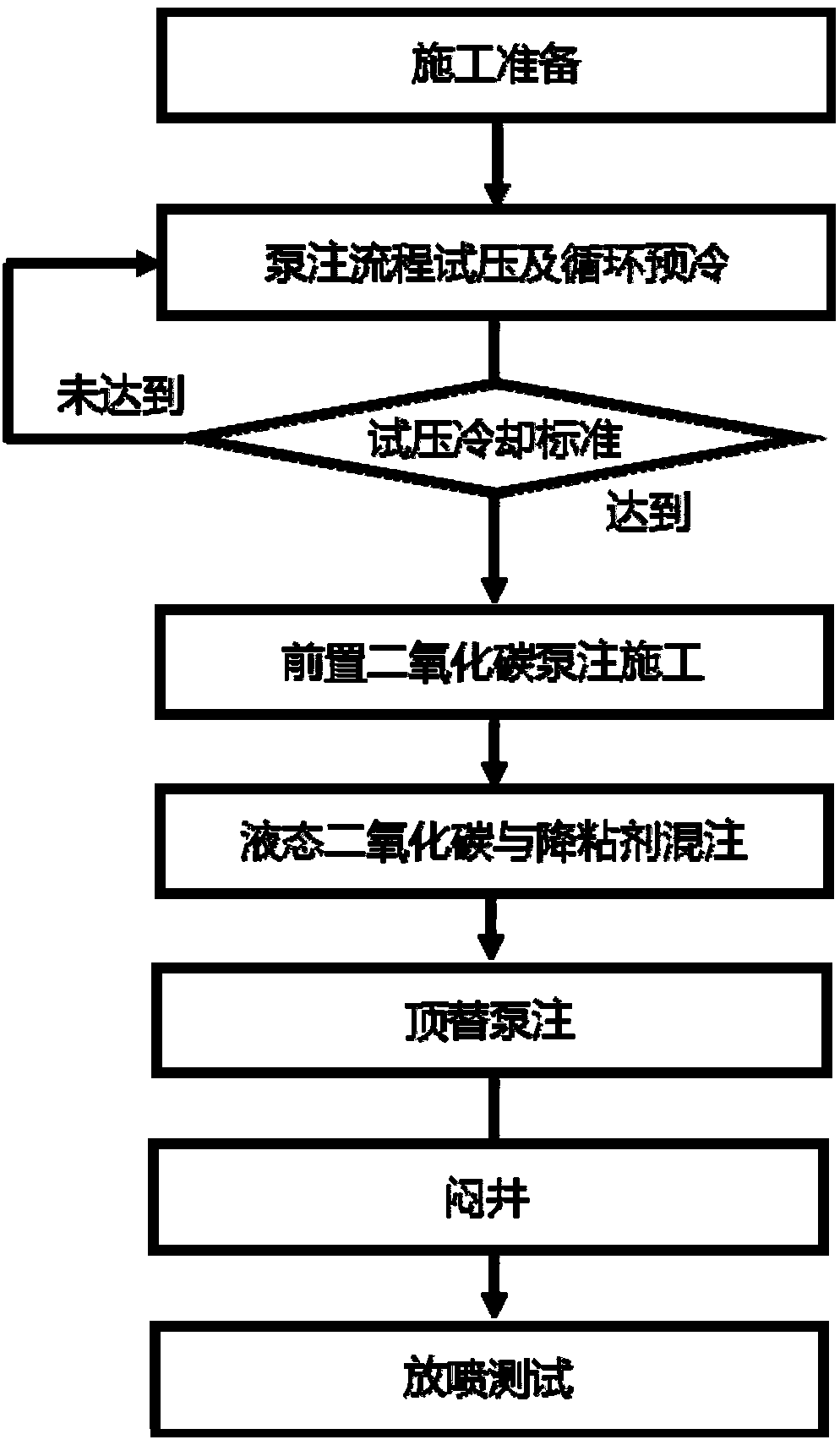

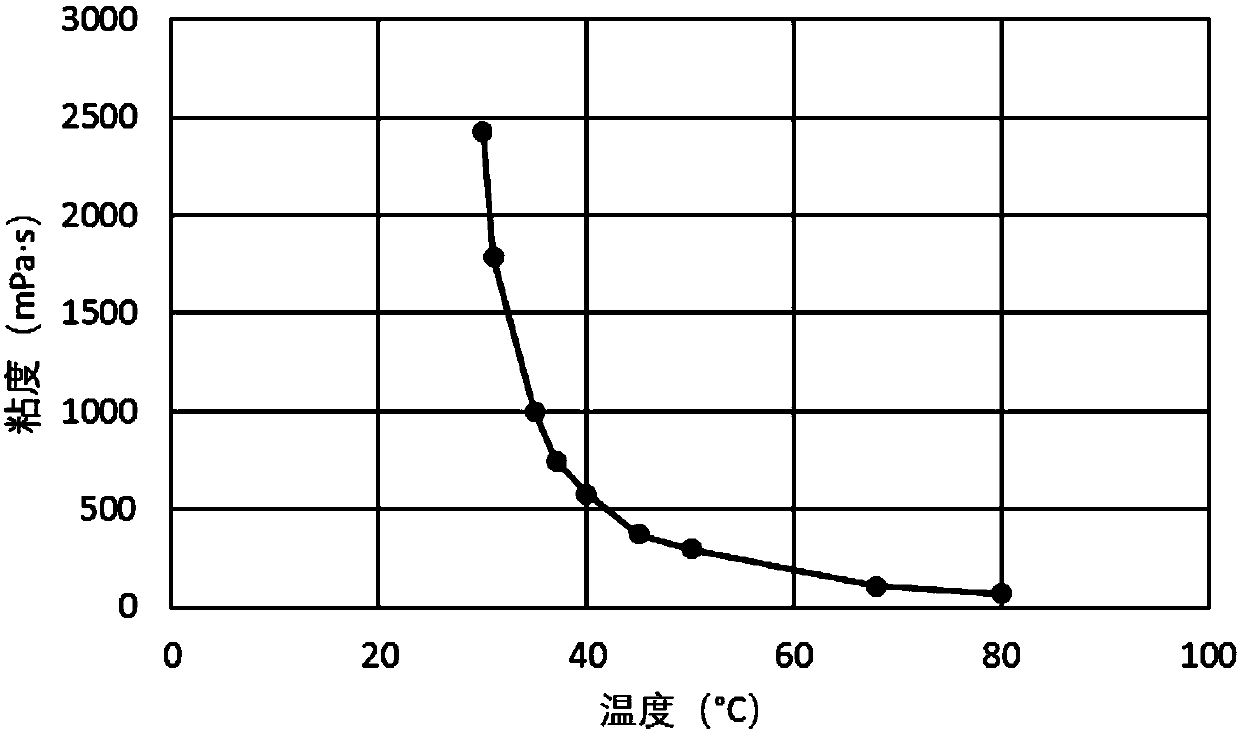

[0024] A carbon dioxide energy storage high pressure viscosity reduction cold recovery method applied to the development of heavy oil reservoirs. The carbon dioxide energy storage high pressure viscosity reduction cold recovery method for heavy oil reservoirs is composed of construction preparation, pump injection process pressure test and cycle precooling, The pre-pumping construction of carbon dioxide, mixed injection of liquid carbon dioxide and viscosity reducer, displacement pumping, stuffy well, blowout test consists of seven steps (such as figure 1 shown).

[0025] in:

[0026] (1) Construction preparation: Prepare corresponding construction equipment and construction materials;

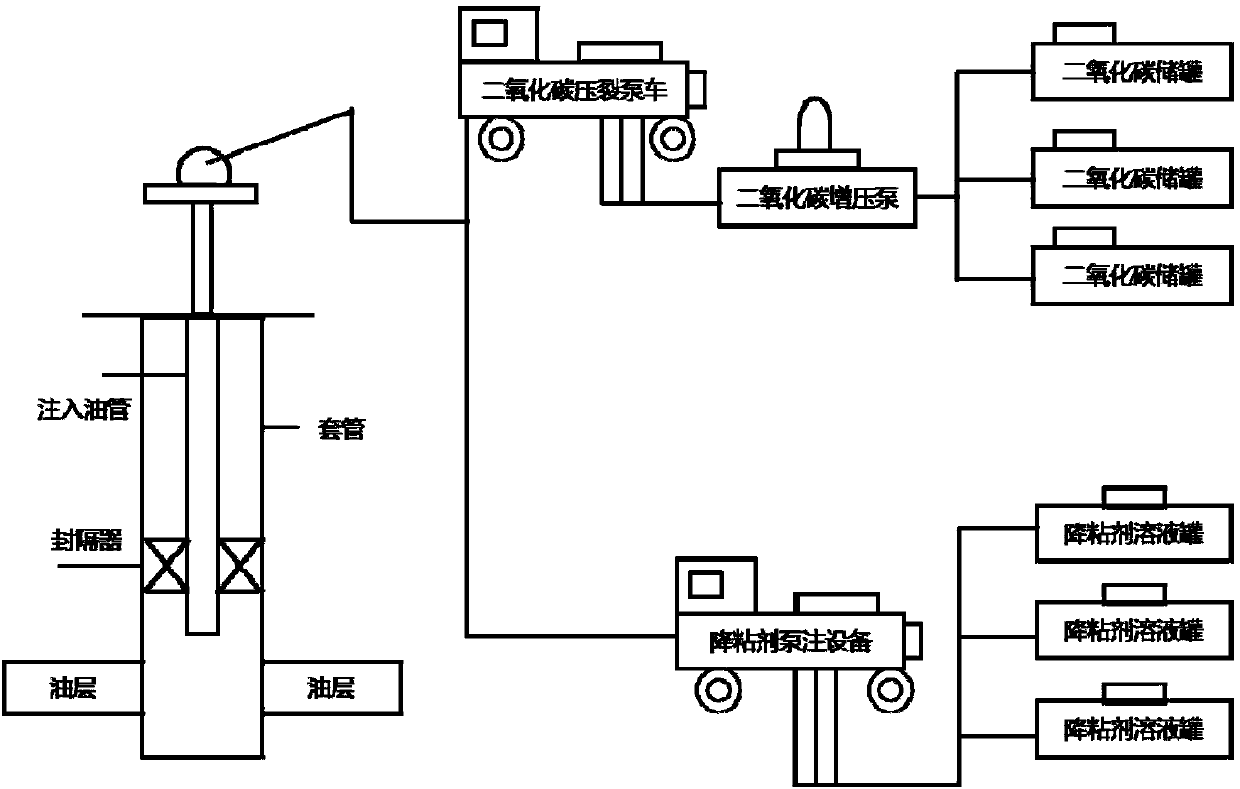

[0027] (2) Pressure test and cycle precooling of pump injection process: according to figure 2 As shown, the process will be connected and the pressure test will be carried out on the ground process part. If the ground pressure test fails, it needs to be rectified. After the pressure test i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com