A heat pump heating system with deep exhaust steam waste heat recovery

A heating system and jet heat pump technology, applied in heat recovery systems, heating systems, household heating, etc., can solve problems such as increasing system investment and operating costs, affecting system performance, and reducing the quality of low-temperature heat sources. The effect of system energy utilization efficiency, system performance improvement, and pump power saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

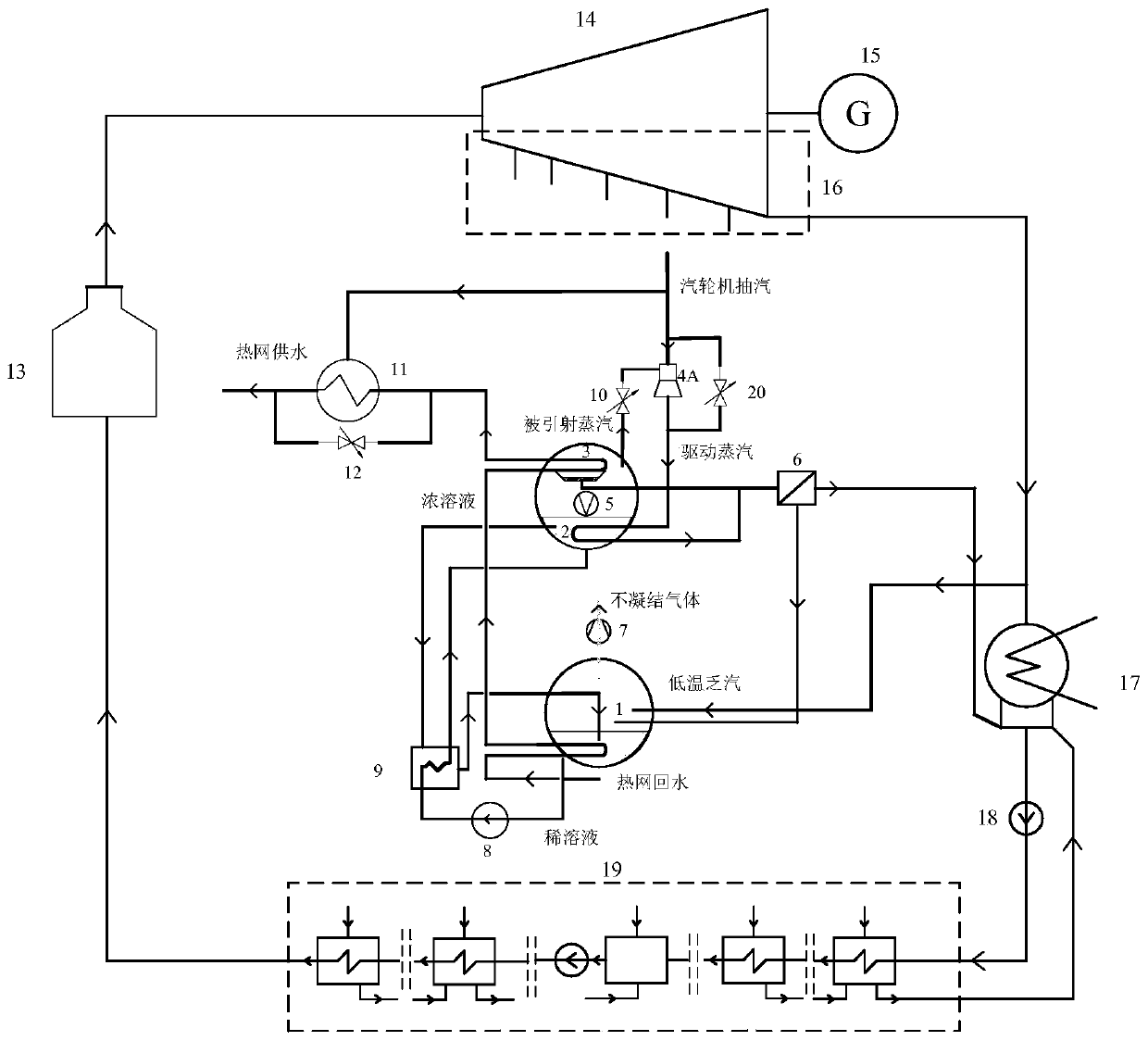

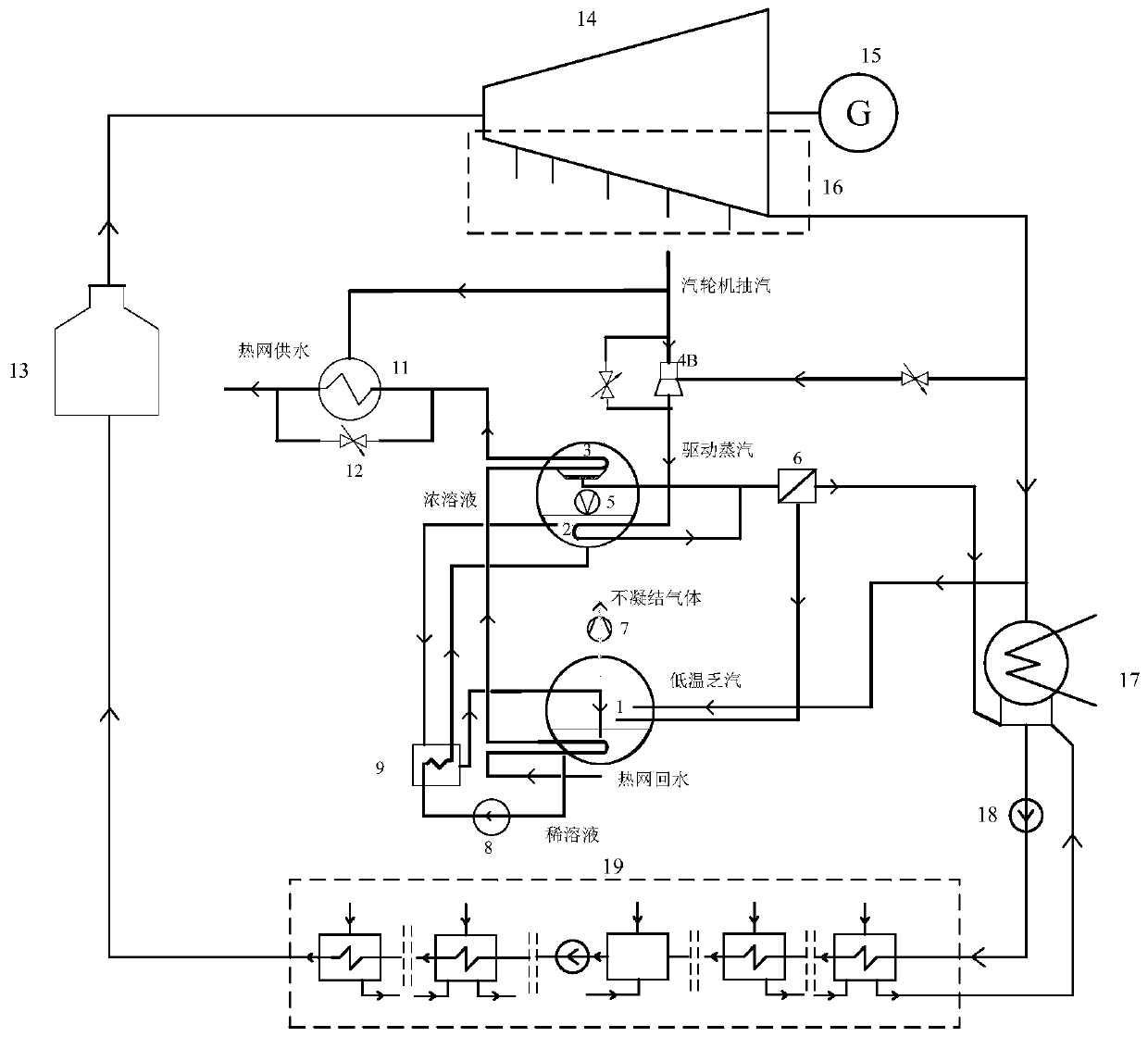

[0013] Attached below Figure 1-3 To further describe the present invention, it should be understood that the content described here is only for illustrating and explaining the present invention, and is not intended to limit the present invention.

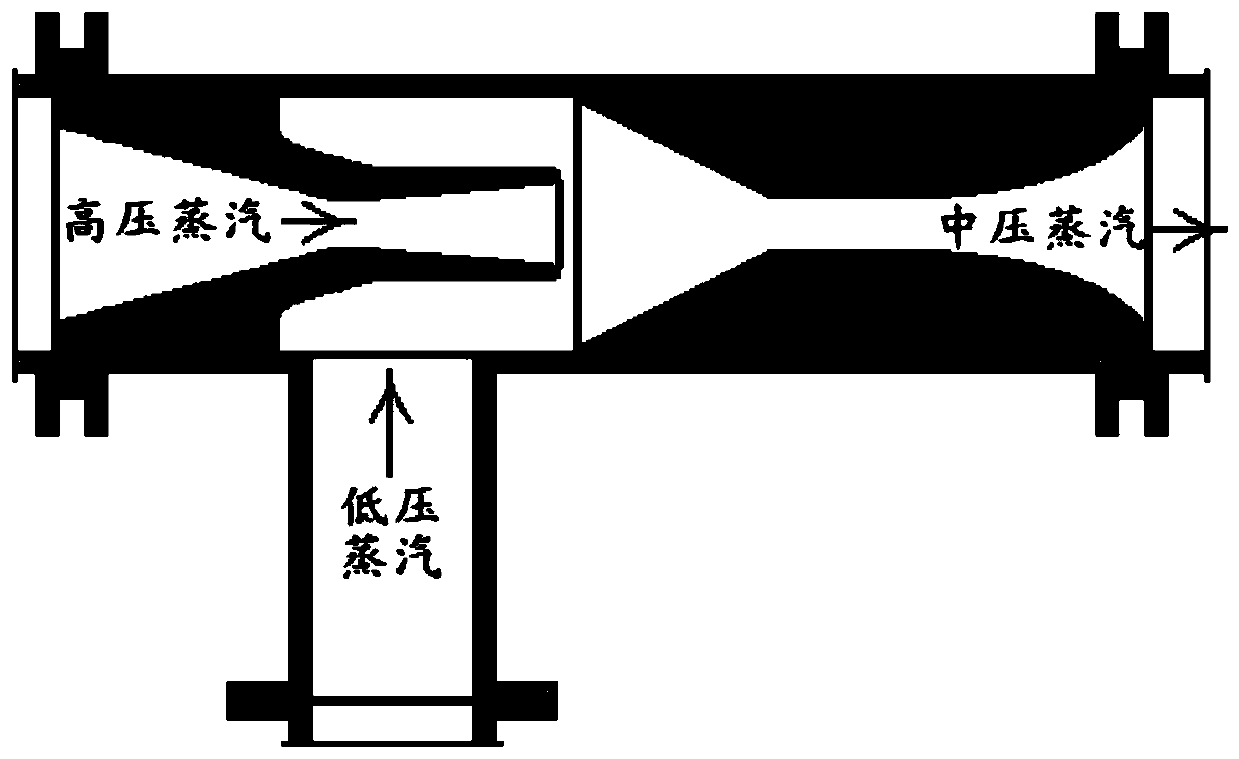

[0014] Jet heat pump is a simple structure, no mechanical moving parts, safe and reliable energy-saving device, widely used in many fields. figure 1 A schematic diagram of the jet heat pump principle is given. The jet heat pump includes a high-pressure steam inlet at the front, a low-pressure steam inlet at the side, and a medium-pressure steam outlet at the end; Steam and low-pressure steam enter the mixing chamber and mix to form medium-pressure steam, which is finally output from the medium-pressure steam outlet at the end. Introduce high-pressure steam from the high-pressure steam inlet as power steam, expand through the nozzle to form a high-speed steam flow, and the pressure drops to form a low-pressure area. The low-pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com