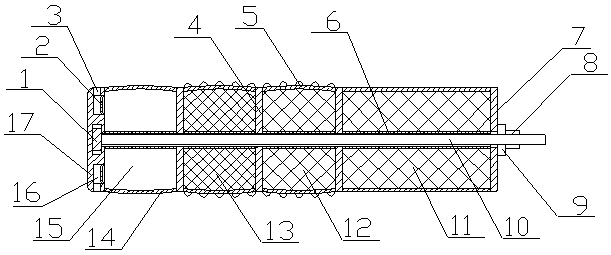

Coal mine blast hole plugging device

A plugging device and blasthole technology, applied in the field of plugging devices and blasthole plugging devices in coal mines, can solve the problems of reducing blasting efficiency, easy plugging, and plugging gaps, so as to reduce the risk of gas explosion and prevent flame injection. , the effect of tight sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028]A coal mine blasthole plugging device of the present invention is realized in this way. When in use, when the blasthole is blocked, the present invention is first inserted into the blasthole, and when the bottom plate (7) is blasted toward the blasthole opening, it is then blasted out of the blasthole. Pull back the screw (10), the screw (10) drives the top plate (17) to move out of the blast hole, and then the elastic sleeve (14) is squeezed and swells, and the multiple rubber sleeves (6) on the screw (10) are respectively pressed Squeeze and compress, the clay in the clay chamber (11) deforms and bulges to seal the outermost side of the blasthole, and the gravel in the gravel chamber (12) deforms and swells under pressure to drive the outer friction protrusion (5) and the inner wall of the blasthole Closely fit, and then block the blast hole in the middle position, the water in the water storage chamber (13) is compressed and deformed to swell, driving the outer frictio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com