Icing monitoring and ice melting integrated system based on optical fiber grating and graphene thin film

A technology of graphene film and optical fiber grating, which is applied in the direction of color/spectral characteristic measurement, etc., can solve the problems of environmental restrictions on the accuracy of detection results, the failure of real-time synchronous monitoring of ice and ice melting devices, etc., to achieve real-time storage and accurate icing signals Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

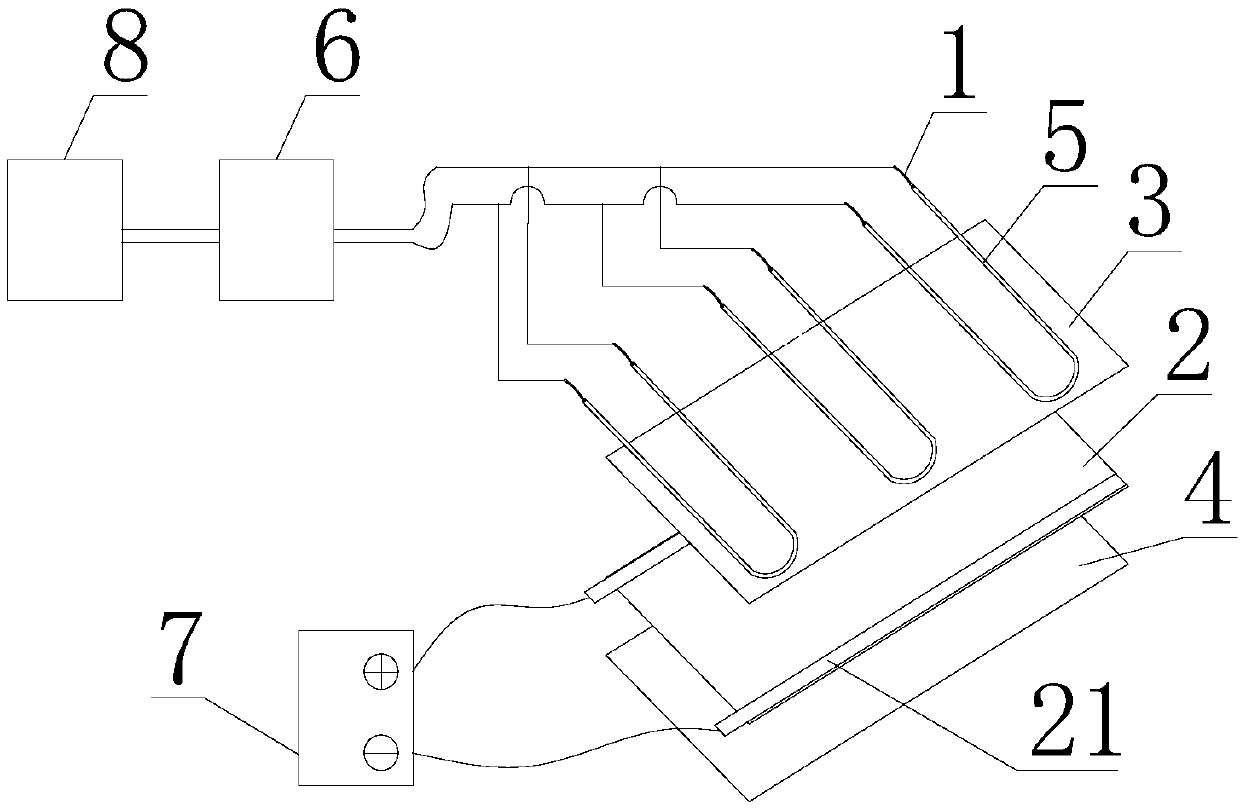

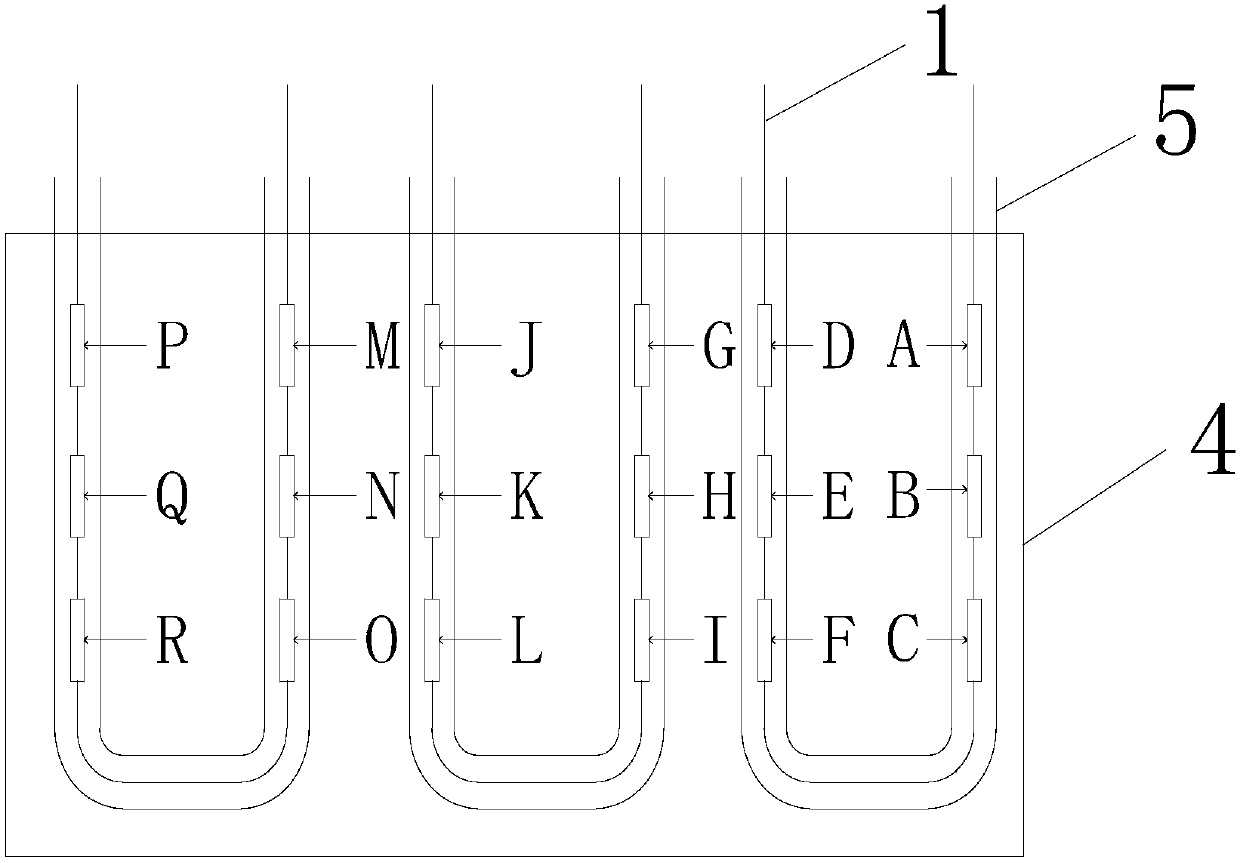

[0033] Specific implementation mode one: combine Figure 1~3 Describe this embodiment, the present embodiment is based on fiber Bragg grating and graphene thin film icing monitoring and ice-melting integrated system by measuring ice and melting ice composite film, fiber Bragg grating sensor demodulator 6, composite film input power supply 7 and computer 8 constitute;

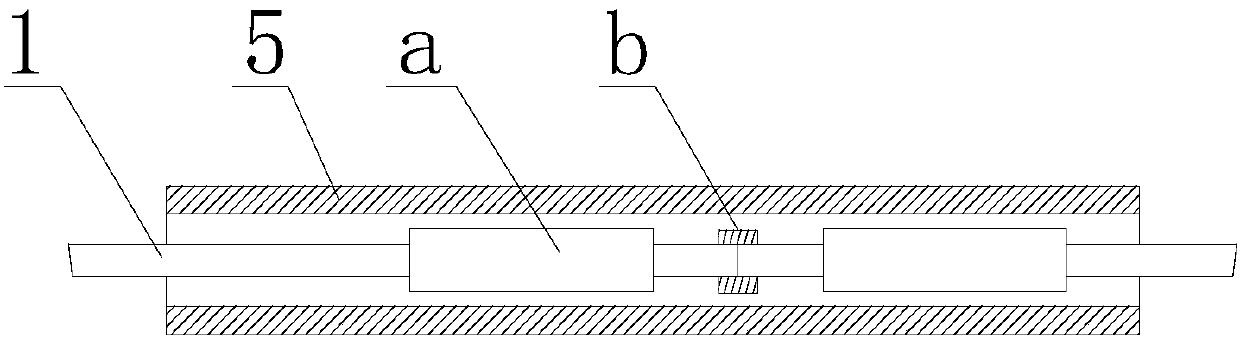

[0034] The ice-measuring and ice-melting composite film consists of several optical fiber Bragg grating sensing strips 1, a graphene film 2, an upper polyethylene terephthalate film 3, a lower polyethylene terephthalate film 4 and Several plastic sleeves 5 are formed;

[0035] The upper polyethylene terephthalate film 3 is arranged on the upper surface of the graphene film 2, and the lower polyethylene terephthalate film 4 is arranged on the lower surface of the graphene film 2, and the graphene film 2 passes through the upper surface The polyethylene terephthalate film 3 and the lower polyethylene terephthalate...

specific Embodiment approach 2

[0042] Embodiment 2: This embodiment differs from Embodiment 1 in that: 3 to 7 fiber Bragg grating sensing strips 1 are arranged per square meter in the ice-measuring and ice-melting composite film. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0043] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the fiber Bragg grating sensor belt 1 is composed of 6 to 40 fiber Bragg grating sensors connected in series. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com