Cu2-xS/g-C3N4 heterojunction photocatalyst and preparation method thereof

A photocatalyst and heterojunction technology, applied in the field of photocatalytic materials, can solve the problems of harsh process conditions, complex preparation process, difficult operation, etc., and achieve the effects of no environmental pollution, simple preparation method, and easy availability of raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

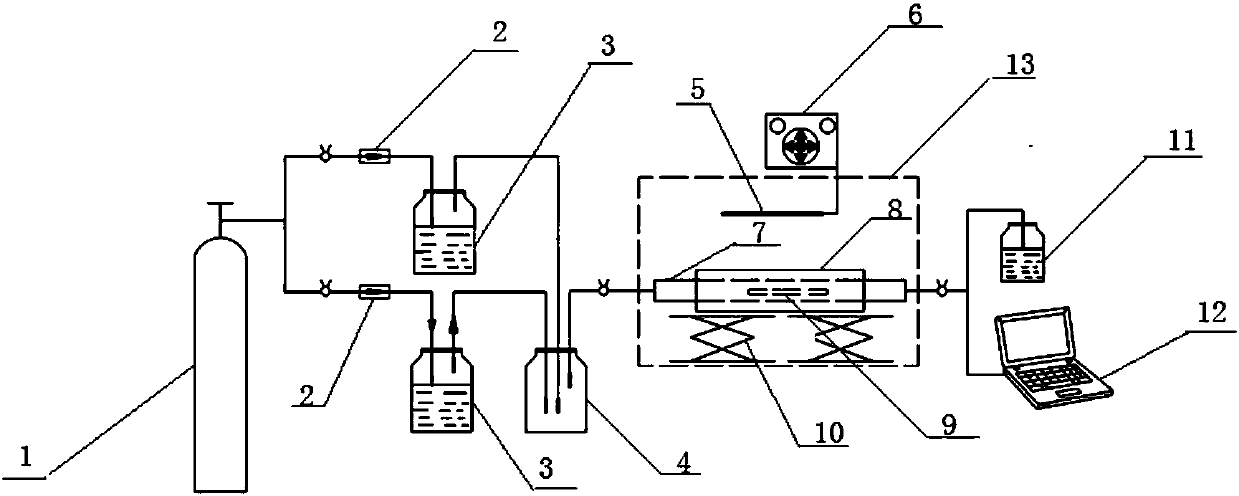

Method used

Image

Examples

Embodiment 1

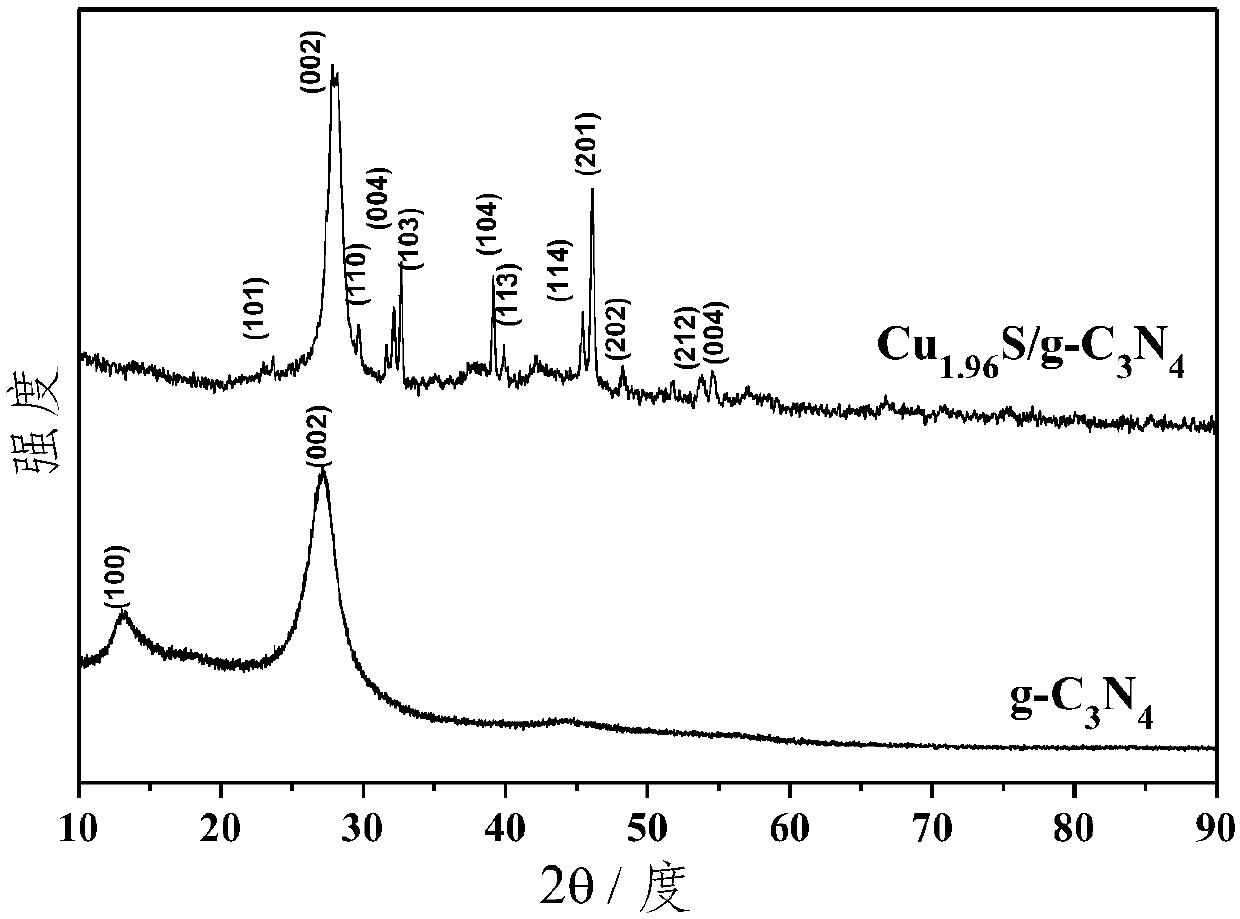

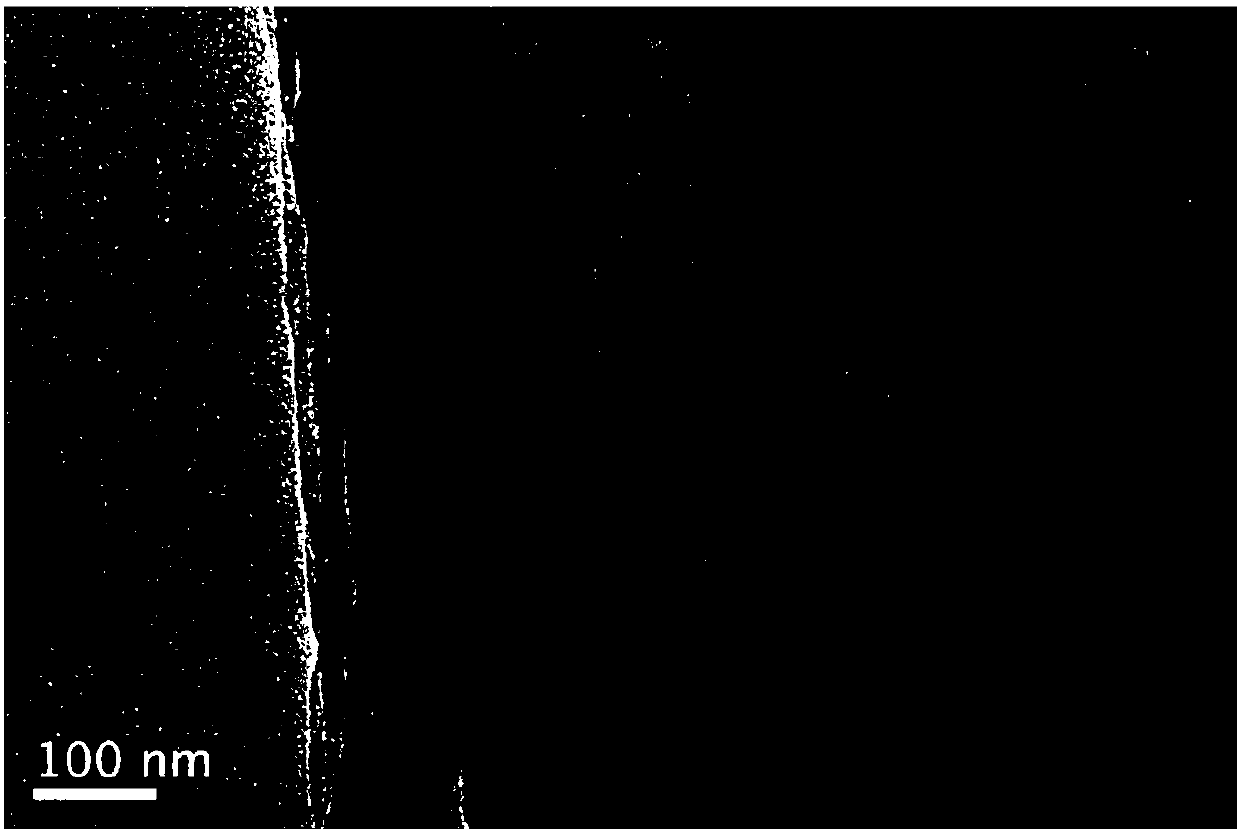

[0021] Mix 5g of thiourea and 1g of copper nitrate uniformly, then place the mixture in a tube furnace, and calcinate at 400°C for 8h under the protection of nitrogen, wash and dry the reacted product with distilled water and absolute ethanol to obtain Cu 2-x S / g-C 3 N 4 heterojunction photocatalysts.

Embodiment 2

[0023] Mix 8g of thiourea and 4g of copper nitrate evenly, then place the mixture in a tube furnace, and calcinate at 500°C for 3h under nitrogen protection, wash and dry the reacted product with distilled water and absolute ethanol to obtain Cu 2-x S / g-C 3 N 4 heterojunction photocatalysts.

Embodiment 3

[0025] Mix 8g of thiourea and 6g of copper nitrate evenly, then place the mixture in a tube furnace, and calcinate at 550°C for 4h under nitrogen protection, wash and dry the reacted product with distilled water and absolute ethanol to obtain Cu 2-x S / g-C 3 N 4 heterojunction photocatalysts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com