Preparation method and application of glutamic acid modified g-C3N4-Cu2O composite catalyst

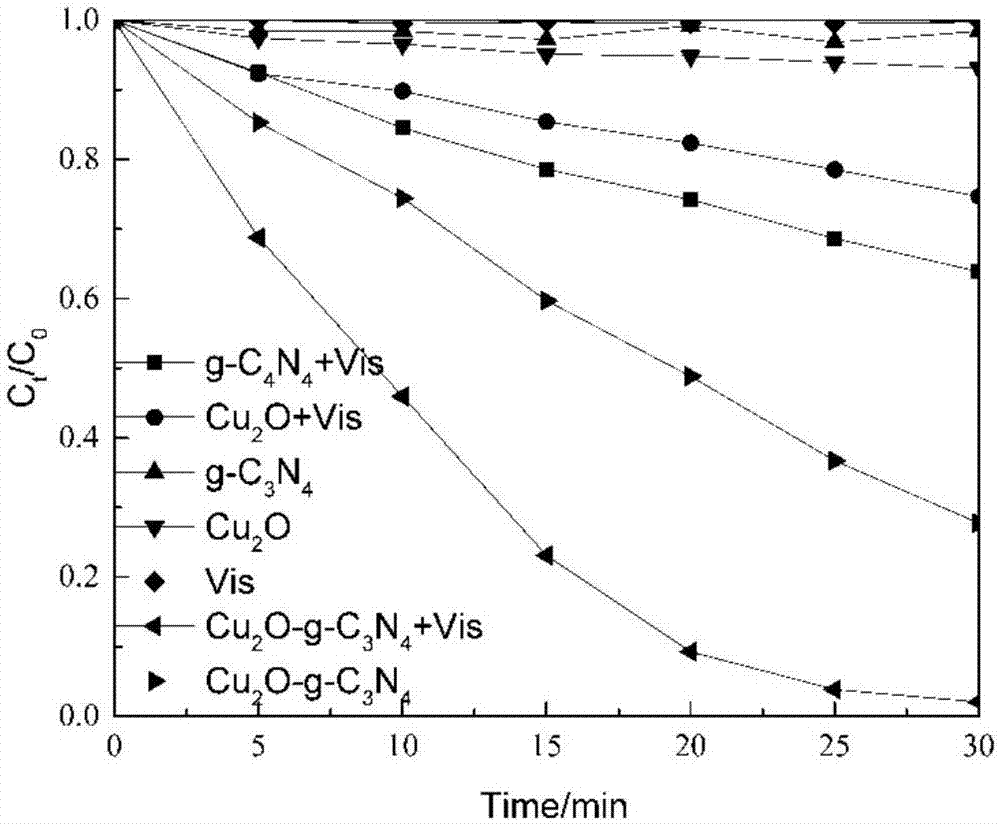

A composite catalyst, glutamic acid technology, applied in physical/chemical process catalysts, chemical instruments and methods, water/sludge/sewage treatment, etc. The effect of photocatalytic performance, good crystallinity, strong visible light absorption ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] Embodiment of the present invention uses PEG to modify g-C 3 N 4 -Cu 2 The preparation method of O composite catalyst, described method comprises the steps:

[0035] obtaining a first solution comprising Cu in dissolved state 2+ , and glutamic acid;

[0036]Add protonated g-C to the first solution 3 N 4 , stirred, sonicated to obtain a suspension;

[0037] Add xylitol to the suspension under stirring, adjust the pH value to 10-12, and stir to obtain a mixed solution;

[0038] Heating the mixed solution to 150-200°C in a high-pressure reaction vessel, and reacting at a constant temperature for 25-35 hours to obtain a reactant;

[0039] The cooled reactant is separated from solid and liquid, washed, and dried in vacuum to obtain a solid product;

[0040] The solid product is heated to 150-250°C under the protection of an inert gas and kept at a constant temperature for 1h-3h to obtain g-C 3 N 4 -Cu 2 O composite catalyst.

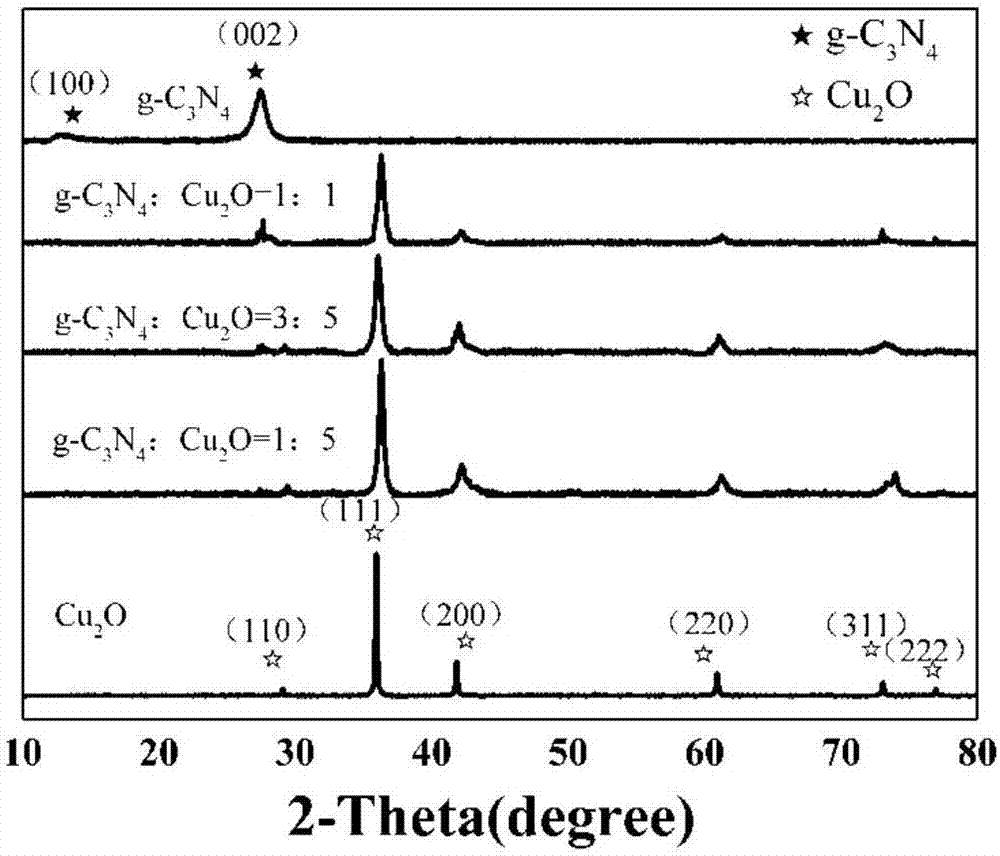

[0041] g-C 3 N 4 It has good chemi...

Embodiment 1

[0048] Raw Materials and Reagents

[0049] Dicyandiamide (C 2 h 4 N 4 ), copper sulfate pentahydrate (CuSO 4 ·5H 2 O), sodium hydroxide (NaOH), and hydrochloric acid (HCl) were of analytical grade (AR), purchased from Sinopharm Chemical Reagent Co., Ltd.; xylitol (C 5 h 12 0 5 ), methyl orange (C 14 h 14 N 3 NaO 3 S) were analytically pure (AR), purchased from Shanghai Aladdin Biochemical Technology Co., Ltd.

[0050] g-C 3 N 4 preparation of

[0051] g-C 3 N 4 -Cu 2 Preparation of O composite catalyst

[0052] First, 1.25 g of CuSO was mixed under magnetic stirring 4 ·5H 2 Add O to 40mL deionized water, add 0.5g glutamic acid, when the solution turns dark blue, continue to add g-C to the above solution 3 N 4 (g-C 3 N 4 : Cu 2 The mass ratio of O is 1:5), after magnetic stirring for 1 h, continue ultrasonication for 1 h to obtain a uniform suspension, then add 1.5 g of xylitol to the above suspension under magnetic stirring, and then use 1 mol / LNaOH s...

Embodiment 2

[0054] The raw materials and reagents are similar to those in Example 1 and will not be repeated here.

[0055] g-C 3 N 4 preparation of

[0056] Preparation of g-C by High Temperature Pyrolysis of Dicyandiamide 3 N 4 : Weigh 4g of dicyandiamide and place it in a corundum crucible with a cover, put the crucible into a muffle furnace, heat up to 500°C with a heating rate of 1k / min in an air atmosphere, and keep it warm for 5h, and wait for the product to naturally After cooling, the obtained yellow powder was ground for 30 min, and the obtained preliminary product was ground for later use. Mix 10ml of concentrated sulfuric acid and add it into a 50ml flask, stir at room temperature for 6h, and sonicate for 2h. The stirred mixture is slowly poured into 100ml of deionized water while stirring. The obtained milky white suspension was centrifuged at 3000 r for 10 min and washed with deionized water. Dry at 80°C. Weigh the acidified g-C 3 N 4 Pour 0.4g into a 200ml flask, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com