Blown sand polishing device of finish machining workpieces

A polishing device and wind sand technology, which is applied in the field of polishing machines, can solve the problems of potential safety hazards easily splashed on workers, difficult cleaning, and scattered waste, so as to protect handicrafts, improve cleanliness, and reduce human labor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

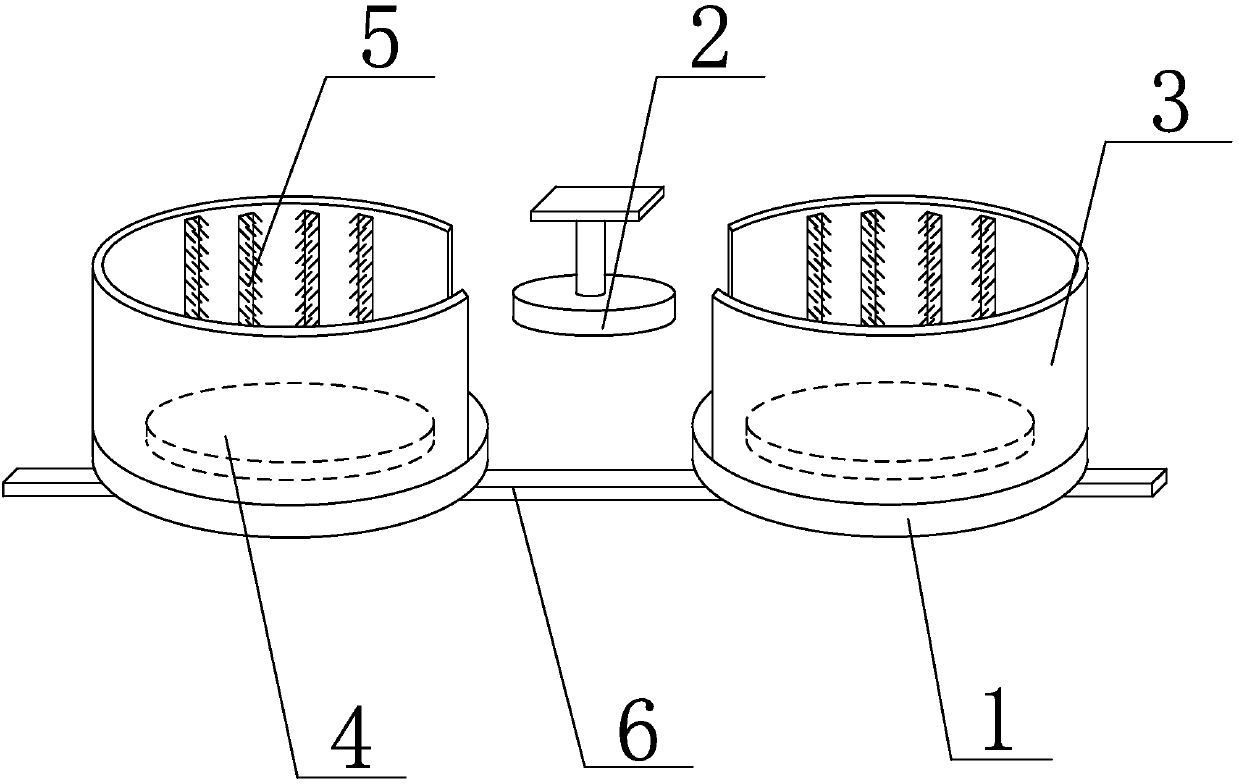

[0022] Such as figure 1 As shown, a wind sand polishing device for finishing workpieces of the present invention includes two polishing workbenches 1 arranged side by side, and a horizontally arranged polishing wheel 2 is arranged between the two polishing workbenches 1. Under the driving of the drive, it rotates horizontally around its own axis. A cylindrical protective cover 3 with a slot notch on the side wall is arranged above the polishing workbench 1. There are two through grooves for the cylindrical protective cover 3 on the two polishing workbenches 1. The gaps are arranged oppositely and are all located on the side where the polishing wheel 2 is located. The length of the through groove gap is the arc of the 1 / 6 cylindrical protective cover 3, and the both sides of the polishing wheel 2 can be embedded in the two through groove gaps. The upper surface of the polishing table 1 in the cylindrical protective cover 3 is provided with a fixed table 4, and a clamping device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com