Horizontal type single-motor bidirectional-driving concrete mixing device

A two-way driving and mixing device technology, which is applied in the direction of cement mixing devices, clay preparation devices, chemical instruments and methods, etc., can solve the problem that the mixing of cement and concrete aggregates affects the strength of building structures, the supply of building materials is becoming more and more difficult, and the impact on construction Structural strength and other issues, to achieve the effect of improving the mixing degree of building aggregate and cement, stable transmission, and improving the strength of building structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

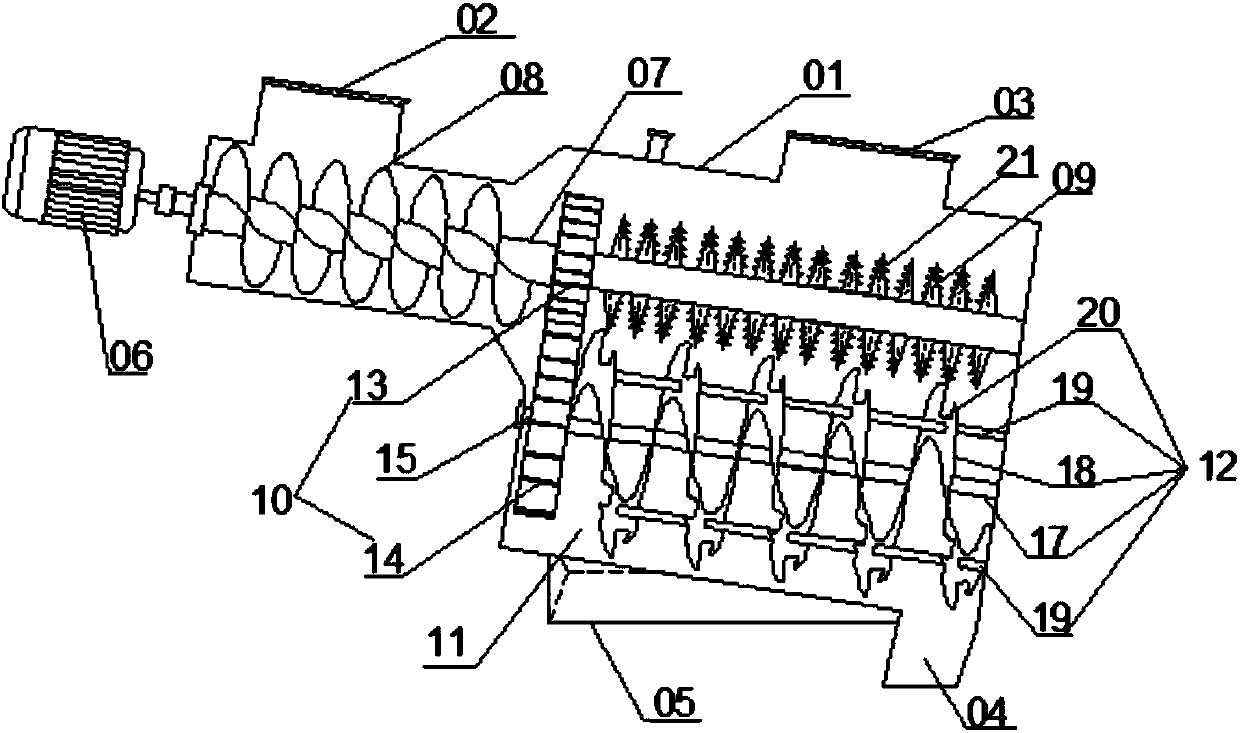

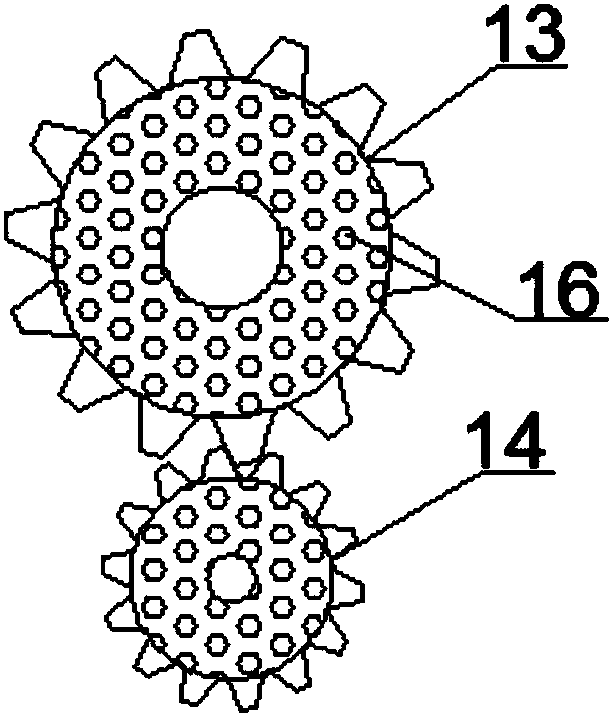

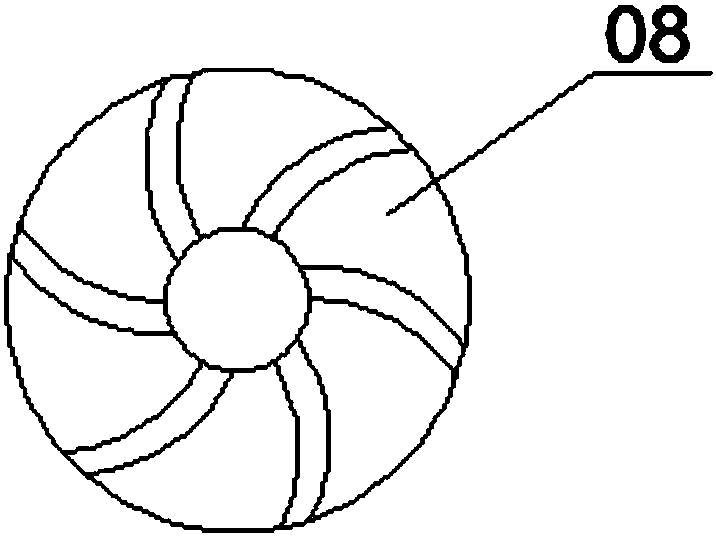

[0027] In order for those skilled in the art to better understand the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and the following embodiments.

[0028] like figure 1 As shown, this embodiment provides a horizontal single-power two-way driving concrete mixing device, including a mixing tank 01, which is installed inclined along the ground, a fixed support seat 05 is provided at the bottom of the mixing tank 01, and the inclination between the mixing tank 01 and the ground The angle is 15°-25°. The setting of inclined horizontal mixing tank 01 is relative to that of pure horizontal mixing tank 01. The material fed in from the feeding port has a certain effect of gravity acceleration, which can speed up the discharge speed of materials. The upper end of the stirring tank 01 is provided with a feed port, and the lower end of the stirring tank 01 is provided with a discharge port 04; specifically...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com