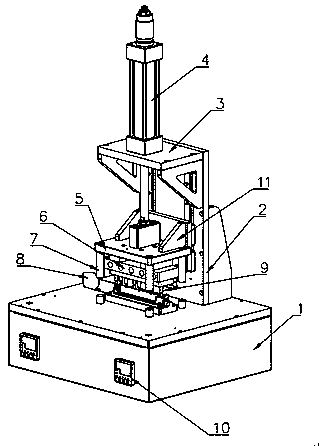

Automatic hot-melting riveting welding machine

A welding machine and riveting mechanism technology, applied in the field of welding machines, can solve the problems of inability to achieve the unification of product process standards, high product defect rate, low work efficiency, etc., and achieve good market application value, easy temperature control, and structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0028]Embodiment 2 is different from Embodiment 1 in that the workbench includes a base, a transmission device and a clamping mechanism, the transmission device is fixed on the base, and multiple clamping mechanisms are arranged on the transmission device, preferably , the transmission device includes a synchronous motor, a synchronous wheel and a synchronous belt, the synchronous wheel is set to two, respectively a driving wheel and a driven wheel, the driving wheel is fixed on the output shaft of the synchronous motor, and the driven wheel passes through the shaft Fixed on the base, the driving wheel and the driven wheel are fixed with a synchronous belt, and the synchronous motor drives the driving wheel and the driven wheel, thereby driving the synchronous belt to move, realizing the movement of the clamping mechanism, and multiple clamping can be set on the synchronous belt The mechanism is used to realize the operation of clamping the plastic workpiece outside the rivetin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com