Cold radiation composite board

A composite board, cold radiation technology, applied in building components, heating methods, lighting and heating equipment, etc., can solve the problems of large spacing between panels, reduced heat transfer efficiency, heat loss, etc., to achieve dense channels and uniform heat transfer. High efficiency and large contact surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

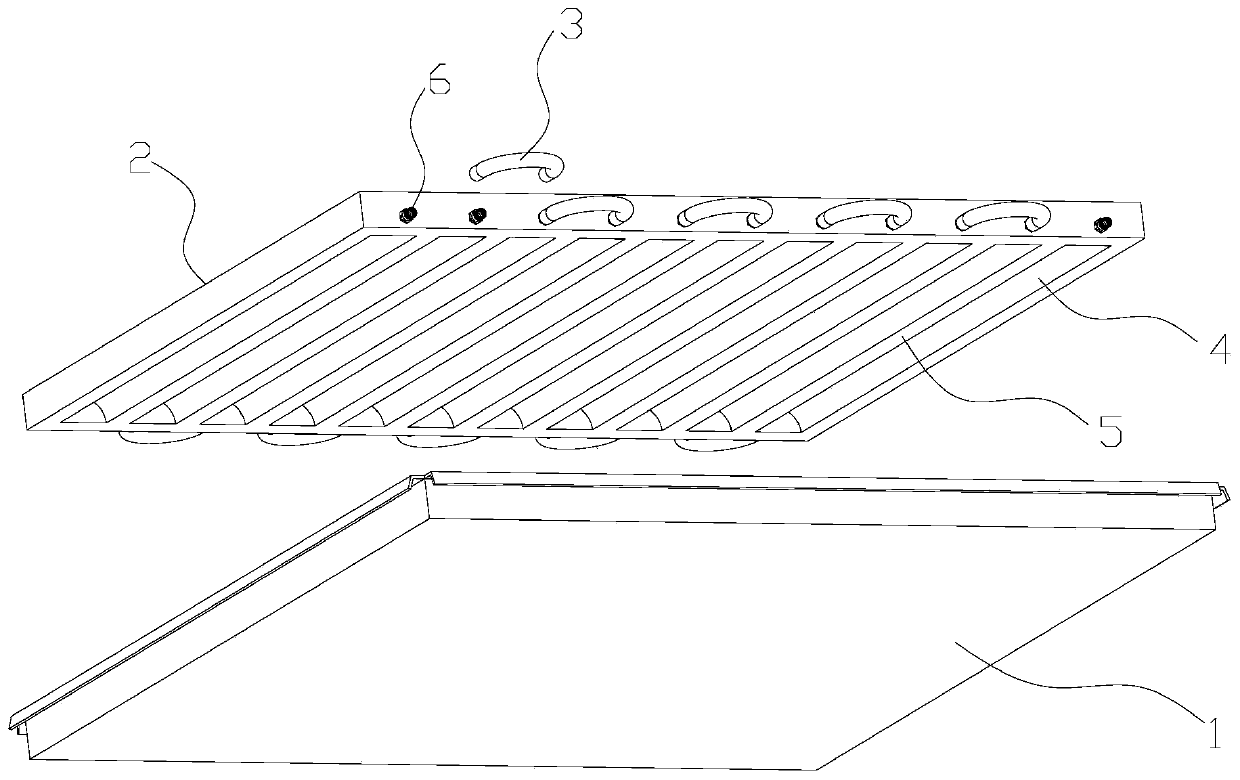

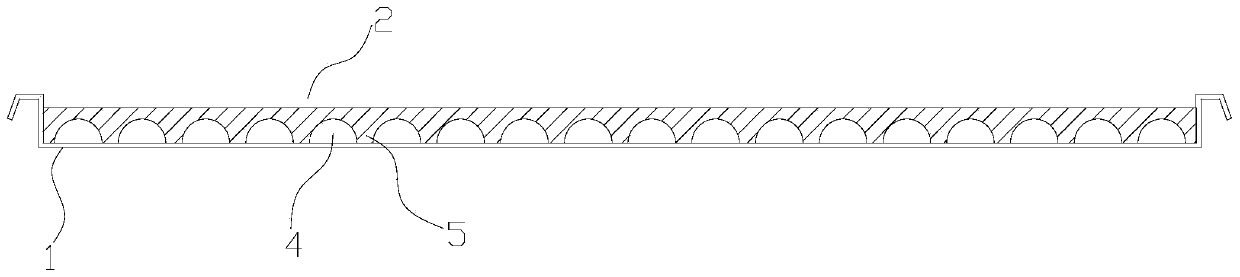

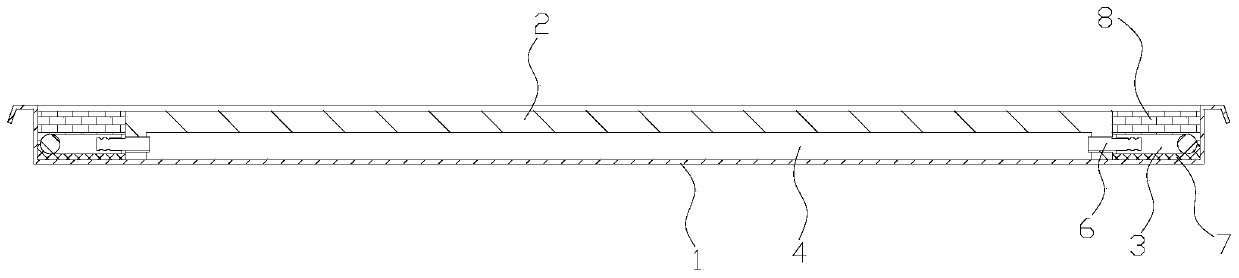

[0035] see Figure 1 to Figure 3 , the embodiment of the present invention provides a cold radiation composite panel, including a panel 1, a thermal insulation backplane 2 and a connecting pipeline 3; the edge of the panel 1 is bent and extended to the back to form a box shape; the thermal insulation backplane 2 is composed of Made of heat-insulating material, it is packaged on the back of the panel 1, and the inner surface of the heat-insulating back plate 2 is provided with a channel 4 for the circulation of the medium liquid. Spacer flange 5; connecting pipeline 3 is located on both sides of the heat insulation backboard 2 and connected to the end of each channel 4, so that all the channels 4 are connected to form a medium liquid channel.

[0036] The greatest feature of the present invention is that the back of the panel 1 does not have the traditional metal coil structure, but a directly sealed heat-insulating back plate 2 instead. The heat-insulating backboard 2 and the...

Embodiment 2

[0045] The only difference between the present embodiment and the first embodiment lies in the connection structure of the connecting pipeline 3, which makes the overall direction structure of the pipeline different.

[0046] see Figure 5 Specifically, preferably, the connecting pipeline 3 includes an inlet main pipe 9, an outlet main pipe 10 and a branch pipe 11; the inlet main pipe 9 extends along the arrangement direction of the channels 4 and is arranged at one end of the channel 4, through which the branch pipe 11 The inlet main pipe 9 communicates with each channel 4 ; the outlet main pipe 10 extends along the arrangement direction of the channels 4 and is arranged at the other end of the channel 4 , and the outlet main pipe 10 communicates with each channel 4 through a branch pipe 11 .

[0047] Different from the coiled pipeline structure of Embodiment 1, this embodiment adopts a straight-line pipeline structure, and the medium liquid is input through the inlet main pi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com